Articles

Executive Viewpoint: Driving a successful energy transition: From natural gas to H2 and beyond

Executive Viewpoint

Driving a successful energy transition: From natural gas to H2 and beyond

Among the many challenges the world will face in the coming years, there is arguably none greater than reversing the tide of climate change. Global warming threatens to disrupt the ecosystems on which we all depend. At the same time, global energy demand is expected to double over the next three decades. This poses an enormous challenge in and of itself, especially considering that today roughly 770 MM people—more than 10% of the world’s current population—lack access to power.1

We believe solving this dilemma and driving a successful energy transition will require a diverse range of sources, including cost-competitive renewables, natural gas and hydrogen (as well as other e-fuels). It will also need strong partnerships and collaboration between private and public sector stakeholders to facilitate innovation and accelerate the commercialization of emerging technologies.

Building a bridge to H2

A large portion of global greenhouse gas (GHG) emissions comes from the energy sector, specifically from fossil fuel-based power generation. In 2018, coal-fired power plants alone represented nearly one third of all CO2 emissions worldwide.2

Although some believe that the growing use of natural gas for power generation is at odds with the buildout of renewables, like solar and wind, it represents the best possible replacement for coal in the near term and can enable significant emissions reductions.

Not only is natural gas abundant and inexpensive when burned in simple-cycle gas turbines, but it also releases up to 50% less CO2 than coal. Even greater decarbonization opportunities are possible if combined-cycle configurations are used (i.e., incorporation of waste heat recovery and a steam turbine), which can yield another 20%–23% reduction in carbon emissions. In fact, with modern gas turbines in cogeneration applications, it is possible to achieve energy efficiencies as high as 85%.3

With natural gas expected to become the largest global energy source in 2026 and to remain so through 2050,4 the critical question is how to make its lifecycle cleaner—from extraction to transportation to end use.

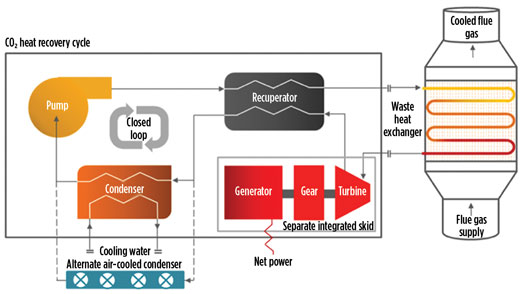

We are working closely with oil and gas customers across the Americas region to address this issue. One specific example is our recent collaboration with TC Energy Corp. Together, our two companies are implementing a first-of-its-kind waste heat-to-power solution at a pipeline compressor station in Canada. The solution, which Siemens Energy helped commercialize, is licensed under Echogen Power Systems and uses supercritical CO2 (sCO2) as the working fluid to capture and convert waste heat from a gas-fired turbine into emissions-free power (Fig. 1). Enough electricity will be generated from the system to power approximately 10,000 homes. It will offset approximately 44,000 t of GHG—the equivalent of taking up to 9,000 vehicles off the road.

Fig. 1. Process flow for supercritical CO2-based waste heat-to-power solution.

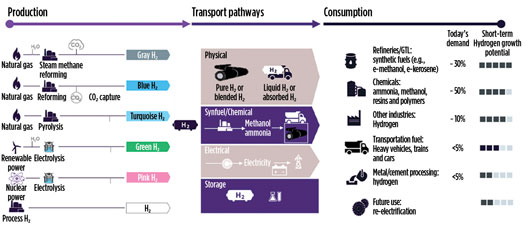

I am confident these types of joint efforts will accelerate as we work to make more sustainable options, such as H2, increasingly economical. In the long term, displacement of natural gas with hydrogen is a viable means of enabling carbon-neutral power plant operation, as H2 combustion produces no CO2. Furthermore, if the H2 being used is “green” or “blue,” the entire process—from H2 production to end use—is entirely emissions-free (Fig. 2).

Fig. 2. The H2 economy will support global decarbonization efforts in myriad ways.

At present, the major impediment to scaling green H2 production is the availability of renewable electricity. It is estimated that 4,700 GW of new renewable generating capacity will be needed to fulfill the H2 demand forecast by 2050 with green H2—nearly five times the world’s current installed base.5 Blue H2 production can be scaled more easily and represents the most feasible option over the next decade.

Although operating large gas turbines with very high H2 content fuel mixtures is not economically viable today, it is within reach for smaller gas turbines. However, even blending in small amounts of H2 with the natural gas fuel stream (i.e., co-firing) can yield impactful emissions reductions. For example, adding just 10% volume of H2 reduces CO2 turbine emissions by 2.7%. Although this may not seem significant, for a 600-MW combined-cycle power plant that runs for 6,000 hr/yr at an average 60% efficiency, it would result in a reduction of approximately 1.26 MM metric t of CO2—the equivalent of taking nearly 275,000 internal combustion engines (ICEs) off the road.a

Many of the gas turbines at Siemens Energy are already capable of burning H2-rich fuel streams. At present, we have 55 gas-H2 turbines in operation worldwide, which have amassed more than 2.5 MM operating hours since the 1960s. Our goal is for all of our turbine models to be compatible with 100% H2 fuel by 2030. We are also taking steps to avoid technological obsolescence by ensuring that all new turbine installations can be upgraded to handle 100% H2 fuel streams. Doing so will enable units that are currently installed (or will be in the near future) to be converted into even more powerful decarbonization agents.

Partnerships to drive innovation

While leveraging existing infrastructure and technologies will be critical to driving a successful energy transition, it is only one piece of the puzzle. The path to an H2 economy—and, more broadly, to carbon neutrality—will require co-creation and collaboration among diverse public and private industry stakeholders to drive innovation. After all, no single company on the planet can reverse the tide of global warming singlehandedly.

Over the past 12 months, I have been extremely encouraged by the growing number of leaders who have embraced this mindset. Never before have so many companies in the energy space showed a willingness to come together and invest in bringing new emissions-reducing technologies to market.

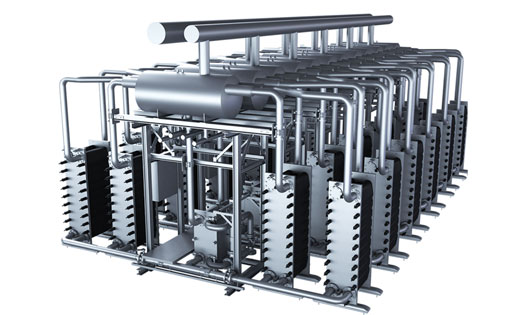

We have been very active in our efforts to co-create with customers and other technology providers to accelerate decarbonization through innovation—the TC Energy collaboration is one example. Another is our recent collaboration with Air Liquide. Together, we are working to advance proton exchange membrane (PEM) electrolysis technology and lay the framework for the mass manufacturing of electrolyzers (Fig. 3).

Fig. 3. Siemens Energy Silyzer 300 PEM module array.

Another example is our joint project with Braskem, the largest producer of thermoplastics resins in the Americas and the world’s leading biopolymer producer. We are designing a cogeneration plant for Braskem in Brazil fueled with residual process gas with high H2 content to reduce water use and CO2 emissions. Our two gas turbines and the advanced combined cycle will generate 38 MW and provide 160 t/hr of steam. Braskem estimates that the upgrade project will reduce the cracking unit’s water consumption by 11.4% and decrease CO2 emissions by 6.3%, mitigating environmental impacts and improving the company’s sustainability target achievement.

These are two of many examples that we believe demonstrate what is possible when industry leaders come together and aspire to serve a common cause.

Considering the human element

To date, much of the dialogue surrounding the H2 economy and the energy transition has been focused on what technologies must be deployed to meet carbon reduction targets. As a result, less attention is given to the human element of the equation. People, however, are the true drivers of change. To be successful, we as energy leaders must attract, develop and unite the brightest minds in a diverse and inclusive environment committed to tackling climate change.

Developing the necessary future-fit workforce will, for the most part, involve directing the existing extensive experience and technological expertise of our existing workforce into new market growth areas through training and upskilling. We may also complement our versatile, vibrant, and experienced workers with specific skill sets in fields such as H2, decarbonization and digitalization to give us the burst of innovation necessary to tackle climate change.

Leaders and executives will also need to demonstrate that we can unlearn old ways and learn new ones. To this end, we must strive to eliminate siloed thinking. It is only through a willingness to change and collaborate that we will drive a successful energy transition.

References:

1 International Energy Agency, “SDG7: Data and Projections, Report extract: Access to electricity,” Paris, France, 2020, online: https://www.iea.org/reports/sdg7-data-and-projections/access-to-electricity

2 International Energy Agency, “Global Energy & CO2 Status Report 2019, Report extract: Emissions,” Paris, France, 2019, online: https://www.iea.org/reports/global-energy-co2-status-report-2019/emissions

3 Siemens Energy, “Hydrogen power with Siemens Energy gas turbines,” Technical paper, online: https://www.siemens-energy.com/global/en/offerings/technical-papers/download-hydrogen-capabilities-gt.html

4 Anouti, Y., R. Kombargi, S. Elborai and R. Hage, “The dawn of green hydrogen: Maintaining the GCC’s edge in a decarbonized world,” strategy& (PwC), 20202, online: https://www.strategyand.pwc.com/m1/en/reports/2020/the-dawn-of-green-hydrogen/the-dawn-of-green-hydrogen.pdf

5 Corner, E., “DNV GL’s Energy Transition Outlook 2020,” World Pipelines, September 8, 2020.

Note

a Assumes a car with annual emissions of 4.6 metric t of CO2.

Arja Talakar is Senior Vice President of the Industrial Applications Products business unit at Siemens Energy. As a member of the Siemens Energy leadership team, he is responsible for the new products business, which includes power generation and rotating equipment for the oil and gas industry. Arja Talakar has extensive leadership experience that covers more than 25 years with Siemens in multiple global roles in the U.S., Germany, South Korea and Saudi Arabia.

Previously, he was CEO of Siemens Saudi Arabia, where he led large international JVs with a focus on projects, manufacturing, solutions and services. Over the past decade, jointly with his team, Arja Talakar has worked on several turnarounds and driven the profitable growth of organizations. As CEO in Saudi Arabia, he helped develop close ties and strategic partnerships with the world’s leading oil and gas, energy and petrochemical companies. The company he led also succeeded in securing and executing large infrastructure projects.

Arja Talakar started his career with Siemens in the fields of engineering and technology for rotating equipment and automation systems, prior to embarking on assignments with increasingresponsibility across the globe. He holds an MBA degree from IMD Business School in Switzerland, as well as an engineering degree from the University of Braunschweig in Germany.

Fig. 1. Process flow for supercritical CO2-based waste heat-to-power solution.

Fig. 2. The H2 economy will support global decarbonization efforts in myriad ways.

Fig. 3. Siemens Energy Silyzer 300 PEM module array.