Articles

CCUS measurement for low-carbon H2 production

Measurement and Instrumentation

CCUS measurement for low-carbon H2 production

The UK has committed to drastically reducing its emissions of carbon dioxide (CO2) and other greenhouse gases and achieving net zero emissions by 2050. To meet this target, substantial changes to the ways in which energy is generated, stored, transported and consumed are required. One potential route to decarbonization involves the use of hydrogen (H2) as an energy vector, to power low-emissions vehicles, for heating homes and buildings, and for industrial applications.

Decarbonization with H2 and CCUS

The H2 pathway, as it is described in the UK Government’s Clean Growth Strategy, is attractive for several reasons. First and foremost, H2 is clean-burning, producing only water as a byproduct, whether it is used in direct combustion or with fuel cells to generate electricity. It should be noted that H2 itself is not a primary energy source (i.e., naturally occurring) and must be produced; however, it can be considered as a means of storing energy. For the overall process to be climate neutral, the H2 must be produced with net zero emissions. This can be achieved in several ways, including the electrolysis of water, provided the electricity used is generated from clean sources such as solar or wind. The H2 produced in this way is often referred to as “green” H2.

It could be argued that using the renewable electricity directly would be more energy efficient, rather than producing green H2, to subsequently convert it back into water. In many cases this is true, but it is important to consider that the supply of renewable electricity is generally intermittent. Solar and wind power are both subject to diurnal and annual fluctuations. At times, the supply will be insufficient to meet demand, and during periods of peak generation there can be an excess, leading to production being curtailed. Producing H2 via electrolysis would provide an energy buffer for when demand cannot be met and could even act as a long-term storage mechanism for energy.

In some processes, it may be preferable to use H2 produced from renewable electricity rather than to use electricity directly. Electric battery vehicles are increasingly common and represent a major step toward the decarbonization of transport. This works well for light-duty vehicles, but the weight and charging times of lithium ion batteries are prohibitive for use with heavy-duty vehicles and long-distance transportation. H2 has a gravimetric energy density of 140 MJ/kg, which is higher than natural gas (53.6 MJ/kg) and diesel (45.6 MJ/kg), and much higher than lithium ion batteries (< 5 MJ/kg). However, in volumetric terms, H2 is the least-dense gas and takes up more space than both natural gas and diesel. When stored as a compressed gas, the volumetric energy density of H2 (2.7 MJ/L at 350 bar or 4.7 MJ/L at 700 bar) is still greater than that of a lithium ion battery (2.2 MJ/L), making it a serious contender for use with larger vehicles, such as HGVs.

Similarly, for the decarbonization of domestic heating, one option is to use heat pumps and electric cooking appliances. However, the replacement of natural gas with H2 in the gas grids is also being considered in many countries, including the UK. This could potentially minimize disruption to end users and allow the gas network infrastructure, and the cumulative skills and experience of its work force, to be repurposed. It would also negate the need to upgrade the UK electricity grid to accommodate the increased electricity generation required. The Clean Growth Strategy estimates that under the electricity pathway, 647 TWh/yr of electricity would need to be generated, a 93% increase compared to the 335 TWh generated in 2018. Under the H2 pathway, the annual electricity requirement would be similar to today, at 339 TWh. The use of H2 could also decarbonize industrial direct flame applications, which are essential to provide many chemical products but cannot be replaced with an electrical equivalent.

A strong case can be made for the use of green H2 in the decarbonized energy supply of the future. However, at present, most H2 is not produced from electrolysis but from a chemical process called reforming, typically either steam methane reforming (SMR) or autothermal reforming (ATR). In these processes, methane reacts with high-temperature steam in the presence of a catalyst and at elevated pressures. Syngas is produced, which is a mixture of H2 and carbon monoxide (CO), before a water-gas shift reaction is used to convert the CO into CO2 and more H2. In the final step, H2 is separated from the CO2 and other impurities by pressure swing adsorption (PSA), a process that exploits the differing tendencies of pressurized gases within a mixture to adsorb to solid surfaces.

Measurement challenges in CCUS

Since the feedstock includes a fossil fuel and the products include CO2, this process is neither renewable nor carbon neutral. It is, however, a viable route to producing vast amounts of H2, enabling the use of H2 vehicles and appliances while the infrastructure to produce green H2 at the scale required is developed. The key question then is how to deal with the CO2 produced? Carbon capture, utilization and storage (CCUS) can be used to create a net-zero emissions process. The UK Government Clean Growth Strategy envisions that 700 TWh of energy could be produced from H2 in 2050, with most H2 produced from reforming, coupled with CCUS to keep the process carbon neutral. The H2 produced from this route is known as “blue” H2.

With CCUS, many potential measurement challenges are expected due to both the physical properties of CO2 and the processes involved in CCUS projects. Crucial to the implementation of large-scale CCUS is the method by which it will be monetized, with numerous different approaches being considered, from taxation through to credit-based systems. Whichever mechanism prevails, monetization requires accurate knowledge of how much CO2 has been sequestered, much the same as custody transfer metering in the oil and gas industry. For context, the UK Oil and Gas Authority requires measurement uncertainty of ±1% for fiscal metering of natural gas, while uncertainties of ±2.5% or less for the total mass of CO2 measured are required under the EU Emissions Trading System (EU ETS).

In addition to the pecuniary aspects, the ability to accurately measure the flowrate of process streams at various points and reconcile this data to provide a holistic mass balance across the entire system will be important for two other reasons. The first is reservoir management, which will require knowledge of the amount of CO2 and other process stream components fed into the geological formation. The second is safety; CO2 is a heavy, asphyxiant gas that can readily pool upon leakage if conditions are correct, and so any breach of system integrity will need to be detected and located quickly.

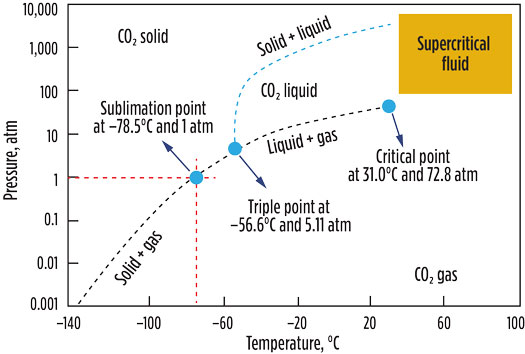

CO2 is unusual because of the closeness of its triple point and critical point to the temperatures and pressures commonly found in industrial processes. Compared to other substances that are transported by pipeline (e.g., oil, natural gas and water), the critical point of CO2 lies close to ambient temperature. This means that even small changes in pressure and temperature may lead to rapid and substantial changes in the physical properties of CO2 (e.g., phase, density, compressibility) (Fig. 1).

Fig. 1. CO2 phase envelope.

In CCUS applications, tightly regulating the temperature and pressure can be a difficult undertaking, particularly over long distances. Pipelines can span hundreds of miles and be subjected to various climates and conditions that affect operating pressure and temperature. When operating near a phase boundary line, there is a risk that the fluid will change phases, or even that multiphase flow conditions will arise. If this occurs at measurement points, it will have a significant detrimental effect on measurement accuracy, where flowmeters are designed to operate in one specific phase.

Impurities in CO2 streams

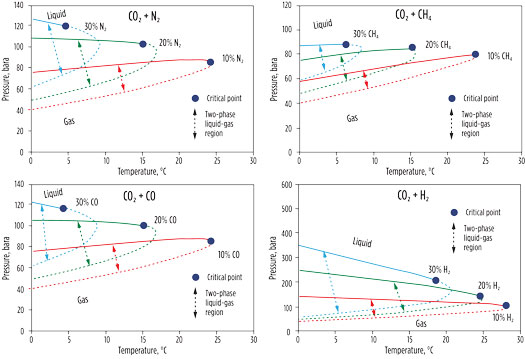

Another major challenge for measurement is coping with impurities in the CO2 stream, which vary depending on the capture process, capture technology and fuel source used. Without knowing the exact phase envelope and physical properties of the CO2 stream, it can be extremely difficult to control the CCUS processes and undertake accurate flow measurement (Fig. 2).

Three main measurements are essential to monitor CO2 across the CCUS chain:

- Composition measurement of the CO2 mixture

- Determination of physical properties

- Flow measurement.

Sampling of the CO2 stream is necessary to determine the CO2 concentration and for the regulatory reporting of other non-CO2 components in the stream. As the composition of the stream will vary continuously, sampling points are necessary at the capture plant and at various points throughout the transportation network where the composition can vary.

Fig. 2. Phase envelopes for CO2 with impurities.

Ensuring flow measurement certainty

After the composition of the stream has been measured, the physical properties can be calculated to provide the necessary data for handling and transporting the CO2 throughout the different parts of the CCUS network and for flow measurement purposes. New equations of state and phase diagrams must be established to accommodate the many different CO2 mixtures that are likely to arise in CCUS schemes.

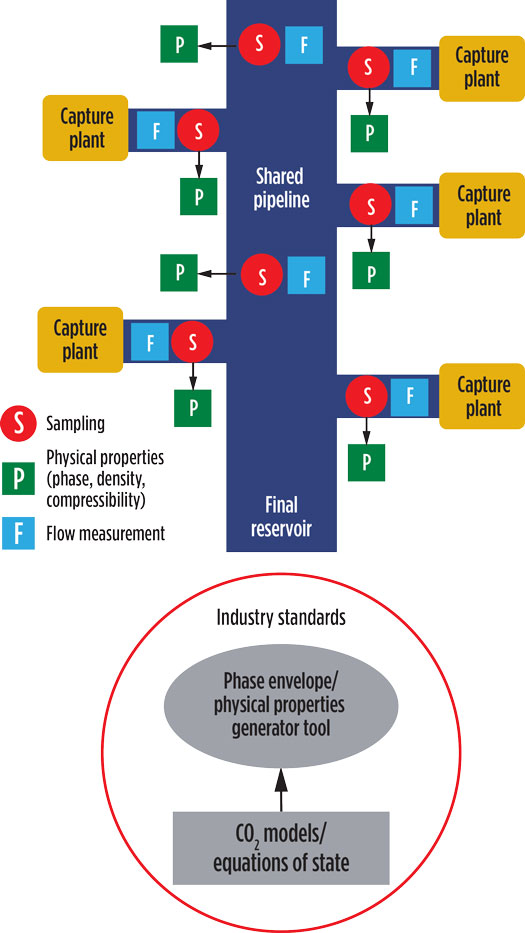

Physical properties software modeling packages can be used to generate new data for the different CO2 mixtures. However, wide variation in results can exist between different software packages and algorithms when used to model the same CO2 mixture. It may be necessary, therefore, to establish validated industry standards and tools to minimize inconsistencies and ensure a uniform approach. This is particularly important in cases where different parties are sharing the same CCUS network (Fig. 3).

Fig. 3. An integrated measurement system in a shared pipeline.

Flow measurement, in conjunction with the CO2 concentration derived from the sampling of the CO2 stream, is required to calculate the transfer of CO2 on a mass basis across the CCUS chain. To meet the EU ETS required measurement uncertainty of ±2.5% for the total mass of CO2 measured, it is essential to install the correct type of flowmeter at locations along the network where the flow conditions are stable, and in the specific phase under which the flowmeter is designed to operate. This may necessitate the use of gas meters at certain locations and liquid meters at other locations along the network.

To ensure and maintain a traceable measurement uncertainty for the purpose of regulatory reporting, flow measurement systems should be calibrated, maintained and inspected at regular intervals. Flowmeters should be calibrated at traceable laboratories, using CO2 at the conditions and ranges under which they will be required to operate. Any secondary instruments used to convert into mass flow, such as pressure, temperature and density instruments, should be calibrated and traceable to national standards and located as close as possible to the flowmeter.

The ability to accurately measure the amount of CO2 sequestered will be a fundamental foundation of large-scale CCUS, but this presents some interesting technical challenges that require an integrated approach to resolve, such as real-time determination of process stream composition, bulk flowrate and fluid properties. The essential technologies exist, but the challenges of integration and economic viability should not be underestimated.

TÜV SÜD National Engineering Laboratory operates a traceable H2 calibration facility for domestic gas flowmeters, and a primary flow standard for validating H2 refueling station dispensers is in development. In addition, capabilities developed for CCUS include gas flowmeter calibration with CO2 and CO2/N2 mixtures at up to 1,000 m3/hr at 25 bar, as well as a facility for testing densitometers, sampling systems and various sensors with CO2 and CCUS mixtures in liquid, gaseous or supercritical states. As the energy transition progresses, it is essential that the UK’s National Measurement System has the capability to support industry needs to meet the target of net zero emissions by 2050.

Dale Anderson is a Clean Fuels Engineer at TÜV SÜD National Engineering Laboratory (NEL), where his primary focus is understanding the flow measurement challenges for H2, CO2 and LNG. Since joining NEL, he has been involved in various projects related to the design and uncertainty assessment of physical testing facilities. Part of the TÜV SÜD Group, NEL is the UK’s Designated Institute for Flow and Density Measurement.