Articles

Key safety considerations for the rollout of H2 infrastructure

Safety and sustainability

Key safety considerations for the rollout of H2 infrastructure

The international hydrogen economy is set to boom in the next few years with Europe emerging as the clear leader in investment and policy support for the sector. Despite the COVID-19 pandemic heavily impacting economies, 2020 saw six European countries, as well as the European Commission, release H2 strategies as part of a green recovery plan.1 Annual global investments are expected to exceed $1 B by 2023, with spending increasing rapidly after that year. With lofty goals of 55% decarbonization by 2030 and net-zero carbon emissions by 2050, five key European countries (France, Germany, Italy, Portugal and Spain) are predicted to invest more than $44 B in blue and green H2 projects.

In the U.S., major oil companies, automakers, H2 producers and fuel cell manufacturers are pushing policymakers to follow Europe’s lead in making a major commitment to H2 infrastructure. In a recent report by McKinsey & Co., “Roadmap to a U.S. hydrogen economy,” forecasts show that H2 for low-carbon sources could supply approximately 14% of the country’s energy needs by 2050.2 The report goes on to state that the U.S. already has an H2 industry valued at about $17.6 B. Reaching the outlined targets could result in $140 B/yr in revenue by 2030 and $750 B/yr by 2050.

The factors driving this rapid acceleration are the decreasing costs of H2 production technology and transportation, and increases in public and government support. To date, government incentives and investments have been instrumental in assisting with the advancement of H2 fueling technology and infrastructure. However, research suggests that state aid to co-fund the H2 network is not enough to drive the buildout of the technology, meaning that costs will need to shift to private industry and public investment. Industry has reported challenges with small stations remaining profitable due to the large capital and operating costs, as well as the limited opportunity to generate income through fuel sales.3 To grow public adoption of H2 technology, education on the safety aspects of H2 and successful mitigation of the risks associated with the technology are of utmost importance.

One aspect of H2 that is under-appreciated outside of the industry is that the technology is well established, which sometimes is not thoroughly understood with increasing interest in new applications of H2 technologies. H2 has been an industrial gas for a long time, and the production, transport and storage logistics are well established. However, for H2 to be used widely as a consumer product, the existing infrastructure must be modified and expanded.1 With falling costs and a push for clean energy, new companies are entering the H2 value chain. These rapidly evolving companies, unlike traditional producers and sellers, may not fully appreciate the unique safety challenges posed by H2.

Recent H2 incidents

As stated previously, it is essential that safety remains an integral part of the aggressive rollout of H2 technology and infrastructure. H2 has unique characteristics and must be handled differently than traditional fuels. Integrating a rigorous approach to risk management early in the process may prevent incidents from happening that disrupt networks, slow the acceptance of H2, or derail the industry indefinitely. The following H2 incidents occurred within a month of one another, each with an important lesson to be learned:4

- Limitations of H2 vehicle fueling infrastructure were demonstrated by the network impacts following the Santa Clara, California explosion

- Poor public perception of H2 safety was evident in protests following the explosion in Gangneung, Korea

- Lack of confidence in technology caused multiple station closures across Europe following the station explosion in Baerum, Norway.

Santa Clara, California. On June 1, 2019, an H2 explosion occurred at the Air Products chemical, gas storage and transportation facility in Santa Clara. In this incident, an H2 tanker truck was being filled when a leak occurred. During the shutdown of the H2 transfer to the tanker truck, an explosion occurred that damaged the emergency shutoff panel and valve near the tanker. While two valves were shut off, the valve closest to the tanker truck could not be closed, and the fire continued to burn for nearly 2 hr. This fire, which was not visible to the human eye, resulted in the shutdown of the Air Products facility through September 2019.

As the only provider of H2 for H2 fueling in the Bay Area region, the shutdown of the Air Products facility resulted in a disruption to the distribution network that lasted for months. While a small supply was available from southern California, the limited availability of fuel was not enough to meet demand. By the time the facility reopened in September 2019, left with no reasonable choice but to abandon their vehicles until fuel supplies returned, many local FCEV owners traded in their cars for low-carbon options such as electric vehicles and hybrids.

Gangneung, Korea. In May 2019, an H2 tank explosion destroyed a complex half the size of a soccer field, killing two people and injuring six more at Gangwon Technopark. Preliminary investigations suggest that the explosion resulted from a spark after oxygen found its way into the tank. This event hampered South Korea’s goal of 1 MM-plus FCEVs on the road when resident groups began protesting stations both planned and under construction around the country (Fig. 1).

Fig. 1. South Korea protests against H2 fuel cell technology.5

South Korea was significantly behind the goal of 114 stations by the end of 2019, with only 29 built. The country has a lot of ground to make up to hit the 310 stations targeted by 2022. Further slowdowns from public protests and a refusal to incorporate H2 technology into existing stations by station owners have been recognized as a show of resistance due to safety concerns.

Baerum, Norway. An Uno-X fueling station experienced an explosion event on June 10, 2019, due to a leak from an improperly installed plug on a high-pressure storage tank. The explosion resulted in two airbag-related injuries from a nearby car and a subsequent fire that burned for approximately 3 hr. Not only did this incident result in a distribution network interruption in Norway, but also the closure of 10 similar stations throughout the Uno-X distribution network. The public, which did not understand or trust the technology, were reluctant to accept the similar stations as safe until an inspection and integrity testing scheme was completed. Knock-on effects continued with Toyota and Hyundai both halting sales of FCEVs in Norway, virtually eliminating the market since they were the only two vehicle providers in the country.

How do regulators and owner-operators cultivate public support and adoption? Looking to other alternative fuel safety regulations may provide a framework for proactively addressing safety and network concerns, rather than reactively addressing public concerns and implementing lessons learned. If a reactive approach is taken (which is common practice for regulatory agencies), H2 technology may hit a significant roadblock in the future.

H2 fueling safety concerns. It is essential that in the accelerated buildout of H2 infrastructure, the focus on safety is not left behind. An area where this is of particular importance is for planned H2 vehicle fueling stations, which if added to existing diesel/gasoline stations, could be near busy intersections or in close proximity to other businesses. However, stations sited based on safe distances for gasoline/diesel may not be safe for alternative fuel infrastructure due to the differences in safety characteristics of the fuel sources requiring larger safety margins.

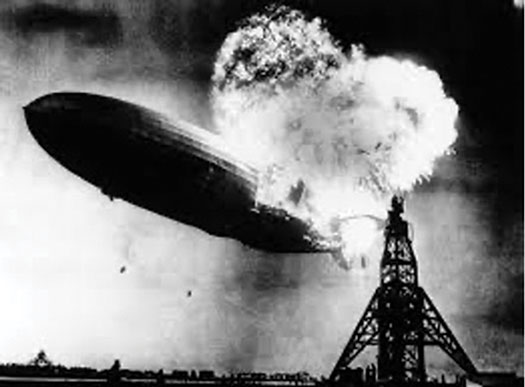

The key to H2 safety is to be aware of all hazards related to the handling and use of the material. Due to historical incidents such as the Hindenburg disaster (Fig. 2) and the public’s perception of H2 bombs (Fig. 3), it is a commonly held belief that H2 is much more dangerous than gasoline/diesel or natural gas. While the worst-case consequences of H2 may be more severe than those of traditional fuels, with a proactive approach to design, infrastructure and safeguards using information learned from incidents and testing programs, H2 can be utilized as fuel at an acceptable level of risk.

Fig. 2. The 1937 Hindenburg Disaster.6

Fig. 3. The 1946–1958 Marshall Islands testing.7

H2 safety concerns are simply different from other fuel sources. The primary H2 hazard is the production of a flammable or explosive mixture in air. H2 has a low minimum energy for ignition (0.02 mJ), meaning that it is easily ignited. H2-air mixtures have nearly an order of magnitude lower ignition energy and a wider flammability range than methane-air mixtures, while the MIE for gasoline and diesel vapors in air are higher than methane-air mixtures. Therefore, major emphasis must be placed on containment, leak detection and ventilation of areas where H2 can accumulate. In chemical processing facilities, safety measures such as elimination of likely sources of ignition, frequent inspection and maintenance, and formal operator training can significantly improve safety. Despite these best practices, leaks, fires and explosions still occur. This inevitability becomes increasingly problematic for H2 vehicle fueling due to the involvement of the public as the primary “operators.”

Lessons learned from existing fueling regulations

While H2 fueling is “new” technology, vehicle fueling is not. The most common vehicle fuels are gasoline and diesel, both of which are readily accepted materials for internal combustion engines (ICEs). Individuals do not question driving to the nearest fueling station and “filling up” with a material that is flammable and capable of forming explosive mixtures in air. We should take a step back to remember that there are inherent risks associated with gasoline and diesel fueling operations, as demonstrated throughout history. As incidents occurred, governments began instituting regulatory requirements such as the Environmental Protection Agency (EPA) Fuel Handling and Storage Regulations in the U.S., and the Petroleum (Consolidation) Regulations and Dangerous Substances and Explosive Atmosphere Regulations in the UK. Even with these regulations, material releases do occur and accidents do happen (Fig. 4).

Fig. 4. Petrol station fire in St. Louis.8

With respect to H2 fueling, one can look to the propane fueling market for lessons learned. In Canada, automotive propane is the most popular alternative fuel. Demand for automotive propane increased dramatically in the 1980s due to the government’s introduction of CA-400 in 1981 to encourage conversion of vehicles to propane fuel. The automotive propane fueling infrastructure naturally followed the bulk storage and loading infrastructure for traditional propane markets.

On August 10, 2008, a boiling liquid expanding vapor explosion (BLEVE) at the Sunrise Propane facility rocked Toronto. This explosion was the result of the illegal practice of swapping propane loads between trucks, which was faster than unloading to and loading from storage tanks. The event forced 12,000 residents to evacuate and resulted in two deaths and dozens of injuries. Houses and businesses near the blast site were destroyed, and the total cleanup bill was approximately C$1.8 MM, with an additional multimillion-dollar class-action lawsuit settlement.9 The Sunrise Propane event caused a significant reaction from regulators and the public, ultimately resulting in new regulations (Fig. 5).

Fig. 5. Sunrise Propane BLEVE.10

The Technical Standards and Safety Authority (TSSA) for the Ontario Province responded to the incident with Ontario Regulation 211/01: Propane Storage and Handling, which requires propane facilities to have risk and safety management plans (RSMPs) in place to ensure public safety.11 The Propane RSMP requires strict risk criteria to be met for offsite impacts as part of a detailed site risk assessment. Unfortunately, because this standard was reactive instead of proactive, it meant that a portion of the propane autofilling infrastructure was not compliant and either had to be taken out of the network (shut down) or brought into compliance, with heavy investment, to make stations safety compliant.

Practices for assessing risk

Regardless of location, safety requirements tend to incorporate one or more of the following approaches to siting: spacing distances, HAZOP/LOPA and/or select detailed modeling. With regard to spacing distances, a number of international standards exist for various parts of the H2 technology process. These standards are often supplemented by local regulatory requirements for minimum design spacing for facility layouts. The problem with spacing distances is that they are not site specific and tend to focus on minimizing equipment damage and business interruption due to small, more likely accidental releases, and they fail to address more severe accidents that could occur with impacts to nearby populations.

Countries with specific regulatory and permitting requirements tend to also require a qualitative hazard review process, such as a hazard and operability study (HAZOP) or layers of protection analysis (LOPA). Using these methodologies to apply order of magnitude consequences and frequency to hazardous events can be challenging with emerging technology in potentially densely populated areas, such as H2 fueling stations. This often involves defining one or more “maximum credible events” (MCEs) and has the unintended consequence of missing low-frequency, catastrophic events as well as high-frequency, low-impact events. As a result, safeguards are identified and selected based on MCEs rather than a thorough range of potential events and the associated risk profile. This is especially troubling for a technology with a lack of historical data on the likelihood of human errors associated with filling activities—a traditionally applied HAZOP/LOPA methodology may struggle to account for these risks in a meaningful way.

In rare instances, detailed modeling is conducted to quantitatively address the hazard and/or risk impacts of a facility. Many of the up-and-coming fueling station owner-operators are utilizing free, open-source software codes with inherent simplifications to conduct risk assessments. While these may be good for a quick answer in some situations, companies should be wary of using any code that they do not fully understand when making important safety and infrastructure decisions. A good rule of thumb is that if it is not readily apparent what calculations are being done and what the model limitations are, then expensive and life-impacting decisions should not be based on those answers.

Key takeaways for safe rollout of H2 infrastructure

To date, the availability of publicly accepted and mandated hazard and risk criteria is limited; therefore, risk assessments are compared to company guidelines or applicable best practices rather than reviewed critically against a given standard. Due to the unique properties of H2 with respect to ignition and explosion characteristics, care must be shown when undertaking detailed hazard and risk modeling to ensure that results are representative of current knowledge and technology. Be wary of falling into the trap of using readily available tools without understanding their basis and limitations. Pitfalls to watch out for include:

- Spacing distances that consider only small hole sizes or are focused on fire events and are generally intended to limit property damage or minimize the likelihood of fire propagation

- Qualitative, experience-based reviews have inherent bias and may lack sufficient knowledge when dealing with new technology and applications without verifying with quantitative analysis

- Assuming that safety shutdown or isolation systems ensure safe operations:

° History has shown us that these systems have limitations and limited reliability

° High-pressure H2 releases form a dangerous flammable vapor cloud, or could lead to a jet fire with lethal impacts faster than the release could feasibly be detected and isolated

- Using models without understanding the basis and limitations of those models (i.e., lack of flexibility to model site-specific conditions, buildings and scenarios)

- Models that do not take into account the surroundings; if the results are the same regardless of the location and neighboring properties, then the answers may not reflect the actual environment and should be investigated further

- Failing to recognize that investing early in safety saves significant money and time over the lifetime of the project and operations.

Companies involved in the aggressive growth of H2 fueling infrastructure should look to the propane fueling industry in Ontario, Canada as an important historical lesson. In this case, one large incident resulted in strict, risk-based regulations. The most cost-effective way to maintain sustainability over the long term is to ensure that risk management keeps pace with infrastructure rollout. This includes a risk-based approach for siting fueling stations by looking at impacts on facility users and nearby populations, as well as evaluating aggregate fueling risks on a yearly basis (i.e., fueling risks on a national level or broader applicable population).

Safe spacing distances and HAZOP/LOPA studies lack the ability to defensibly estimate potential consequences and do not tell an owner-operator about the risk exposure for surrounding areas. Furthermore, because H2 poses more severe jet fire and vapor cloud explosion hazards than gasoline or diesel, assuming the safe siting of gasoline stations is adequate for a station that also handles high-pressure H2 may lead down a dangerous and unsafe path.

Finally, it is recommended to look to traditional H2 producers for guidance on safely operating H2 installations. These long-term companies have learned over years of experience the rigor that should be used when properly managing H2 risks. Companies that have produced and sold H2 understand that H2 can be handled safely, but it requires thoroughly examining risk exposure early and often. Those knowledgeable of H2 hazards can help navigate the challenges of safely and aggressively pursuing H2 infrastructure growth.

Literature cited

1 Adler, K., “Europe emerges as leader in hydrogen economy,” December 15, 2020, IHS Markit, online: https://ihsmarkit.com/research-analysis/europe-emerges-as-leader-in-hydrogen-economy.html#:~:text=The%20EC’s%20hydrogen%20roadmap%20estimated,carbon%20fossil%20fuel%2Dbased%20hydrogen

2 St. John, J., “Can the US catch up in the green hydrogen economy?” Green Tech Media, October 5, 2020.

3 California Air Resources Board (CARB), “Annual evaluation of fuel cell electric vehicle deployment & hydrogen fuel station network development,” July 2019, online: www.arb.ca.gov

4 Vilas, K. R. and R. J. Magraw, “Why proactive assessment of hydrogen fueling risks is essential,” HAZARDS 30, Institute of Chemical Engineers (IChemE) Conference, November 2020.

5 Jin, H. and J. Chung, “Hydrogen hurdles: a deadly blast hampers South Korea’s big fuel cell car bet,” Reuters, 2019, online: https://www.reuters.com/article/us-autos-hydrogen-southkorea-insight/hydrogen-hurdles-a-deadly-blast-hampers-south-koreas-big-fuel-cell-car-bet-idUSKBN1W936A

6 De Syon, G., “Why the Hindenburg disaster is still worth remembering,” Time, 2017, online: https://time.com/4764799/hindenburg-disaster-80-years

7 Abadi, M., “The US dropped 67 nuclear bombs on this tiny island nation—and now it’s far more radioactive than we thought,” Business Insider, 2016, online: https://www.businessinsider.com/marshall-islands-nuclear-bombs-radiation-2016-6

8 Wicentowski, D., “Incredible dumbass turns Lamborghini into fireball at St. Louis gas station,” Rivertfront Times, 2018, online: https://www.riverfronttimes.com/newsblog/2018/07/09/incredible-dumbass-turns-lamborghini-into-fireball-at-kirkwood-gas-station

9 Doherty, B., “Sunrise Propane plant explodes,” The Star, August 10, 2008, online: https://www.thestar.com/news/gta/2016/08/10/august-10-2008-sunrise-propane-plant-explodes.html

10 Alchetron, “Toronto propane explosion,” 2018, online: https://alchetron.com/Toronto-propane-explosion

11 Technical Standards & Safety Authority (TSSA), “Propane RSMP,” Ontario, Canada, 2017, online: https://www.tssa.org/en/fuels/propane-rsmp.aspx

Karen Vilas is the Supervisor of Business Development and Marketing at Baker Engineering and Risk Consultants Inc. (BakerRisk) in Houston, Texas. She is also a Principal Consultant in the Houston Process Safety Group, specializing in consequence and risk modeling as well as insurance risk engineering. Ms. Vilas has worked extensively with clients in the refining and petrochemical industries with a focus on risk quantification and mitigation of blast, toxic, flammable and fire hazards. In addition to servicing clients’ process safety needs, she oversees the business development and marketing group, focusing on industry education of key risk management topics through conference technical content coordination and media content development.