Articles

Technology Spotlight

Adrienne Blume, Editor-in-Chief

GREEN H2

Offshore green H2 jack-up rig concept planned for North Sea

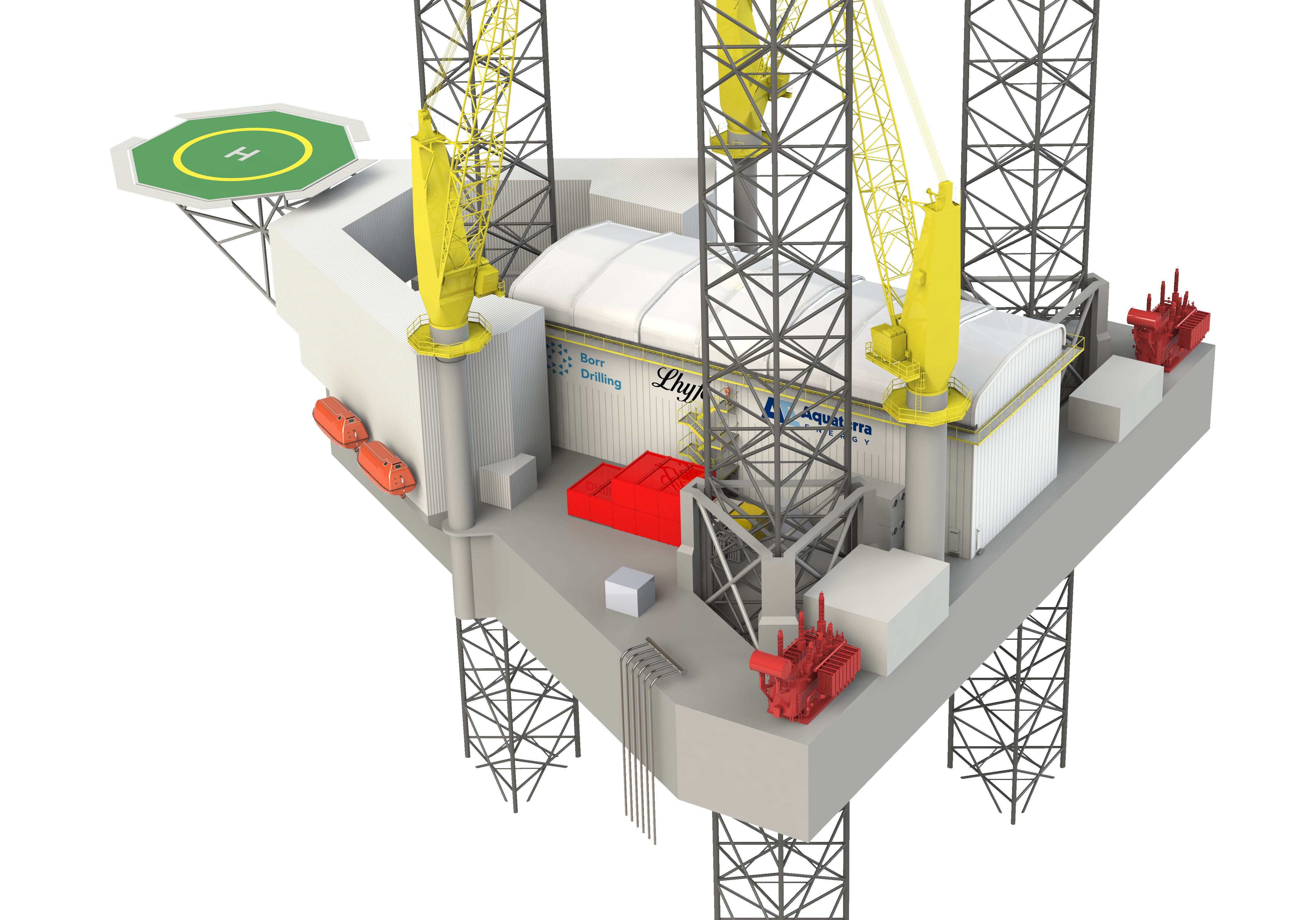

Aquaterra Energy has signed a partnership with Lhyfe and Borr Drilling to develop an innovative concept for offshore green H2 production in the North Sea. The organizations behind Project Haldane will develop an industrial-scale, offshore green H2 production concept, through the deployment of an electrolyzer system on a converted jack-up rig.

Reliable winds far out in the North Sea are an exceptional renewable resource, yet remote locations create challenges around grid connectivity and intermittency of supply. This unique, flexible solution will solve this issue by providing an offtake for the electricity produced in the immediate vicinity of the windfarm and aims to use existing platforms, pipelines, terminal infrastructure and offshore equipment leveraging the existing infrastructure to reduce costs.

Lhyfe is already producing renewable H2 in industrial quantities onshore, with a direct connection to renewable energy, pumping sea water and purifying it to feed the electrolysis process. The production process, therefore, already considers offshore harsh conditions. Over the last few years, Lhyfe has also worked on different projects to deploy its production process offshore.

According to Lhyfe, offshore wind offers the greatest potential for sustainable H2 production because of the cost-effectiveness that can be achieved through scalability and technological innovation.

Permascand, Verdagy to develop electrochemical cell for green H2 production

Permascand Top Holding AB has signed a collaboration agreement with Verdagy for the development of a novel electrochemical cell to produce green H2. The agreement will accelerate the commercialization of the electrochemical cell that is the foundation for the Verdagy Water Electrolysis (VWE) process.

Verdagy and Permascand will collaborate on the development and commercialization of a novel large-aspect-ratio electrolysis cell capable of managing the heat and stress created by operating at much higher current densities than presently available with water electrolysis technology. The nearly 3-m2 cell and membrane architecture are key to dramatically lowering the upfront capital costs of a cell and system. Taken together, very large cells operating at high current densities are more productive, thereby lowering H2 production costs.

By partnering together, Verdagy and Permascand will be able to bring this technology to the broader market with the unprecedented speed necessary to accomplish net-zero goals. Furthermore, Verdagy is modifying its pilot plant facilities in Moss Landing, California to operate 200-kW cells at current densities two to four greater than its nearest competitor.

Cummins to scale up green H2 production with SOEC automation

Cummins Inc. has been awarded $5 MM from the U.S. Department of Energy’s Hydrogen and Fuel Cell Technologies Office for the automation of solid oxide electrolyzer cell (SOEC) and stack assembly, reducing capital costs and facilitating the scaleup of the H2 economy.

The aim of the 3-yr project is automated assembly of an SOEC stack with low direct labor input, increased cell throughput and a 100% quality control check. Following successful development, the automation concept should enable over 100 MW of electrolyzer production capacity.

SOECs operate at much higher temperatures than PEM and alkaline electrolyzers, giving this technology the potential to become more efficient, especially when coupled with industrial processes that utilize steam or high-grade heat. This makes SOECs a potentially important tool in efforts to decarbonize industrial sectors, such as steel production and e-fuels like ammonia.

STORAGE

C-Crete Technologies to develop H2 storage materials

C-Crete Technologies entered into a cooperative agreement with the U.S. Department of Energy to develop and commercialize a new class of nanoengineered materials for storing H2 onsite at industrial plants where it is produced as a byproduct. The H2 could later be used as energy at the same site where it was produced and stored.

The new material would be low cost and scalable, while exhibiting a desirable balance among the storage capacity, the charge and discharge speeds, and the energy required to do those things, otherwise known as the capacity-kinetics-thermodynamics relationship.

Not only will the new material be capable of long-duration storage, but also the subsequent use of the H2 byproduct in the industrial plants where it is produced. This means there would be no transportation or shipment required for the H2. For example, utility companies could store their H2 byproduct, which would otherwise be vented out as waste, in the sorbent material, and then months later use it to generate electricity when the grid demands more.

While H2 production and conversion are mature, its large-scale utilization is impeded by the lack of efficient storage. At present, none of the storage options in the market satisfy the needs of end users, especially for long-duration storage.

The new, nanoengineered materials would be an improvement over existing technologies, such as liquid H2, hydrides and salt caverns, which are good on capacity, kinetics or thermodynamics, but not all three. For example, hydrides have very high H2 uptake capacity, but their release kinetics are slow. The new material would have high H2 uptake, fast kinetics and be scalable, with low cost, as compared to present options.

C-Crete plans to offer its solution as a modular storage system that can be modified for specific types of H2 streams in industrial processes, providing a fresh path to low-cost and efficient long-duration energy storage.

POWER GENERATION

McPhy to equip COEG plant with alkaline electrolyzer technology

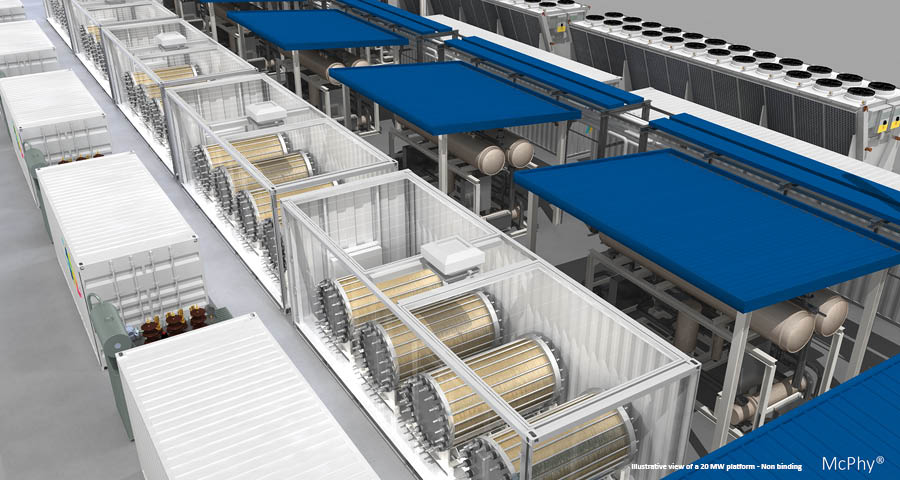

McPhy has been selected to equip the Centrale Électrique de l’Ouest Guyanais (CEOG, or the Western French Guiana Power Plant), the world’s largest power plant project combining photovoltaic energy and massive storage of 128 MWh, mainly in the form of H2.

Combining a photovoltaic solar farm, a high-power, 16-MW electrolyzer, an H2 storage unit and high-power fuel cells, the CEOG plant will produce H2 that will be stored under pressure in tanks. This H2 will then be recombined with O2 from the air in fuel cells to produce continuous, non-polluting electricity and secure the supply of competitively priced electricity to 10,000 households in French Guiana.

The H2 production platform, scheduled to be commissioned in 2024, will be equipped with McPhy’s “Augmented McLyzer” technology. The combination of high-pressure alkaline electrolysis (30 bar) and high-current-density electrodes will enable almost 860 tpy of green H2.

Based on non-polluting energies, CEOG will avoid the emission of 39,000 tpy of CO2, compared to a fossil fuel power plant. This project will also be the first time that McPhy will offer an outdoor version of its alkaline electrolysis technology. In addition to being the most suitable solution for an isolated geographical area, containerization ensures a high level of profitability for the customer. The reduction in civil engineering costs and the preassembly of the equipment directly in McPhy’s plants make it possible to optimize time and total installation and assembly costs.

Panasonic launches 5-kW H2 fuel cell generator

Panasonic Corp. has developed a pure H2 fuel cell generator, which generates power through a chemical reaction with high-purity H2 and O2 in the air. The generator was launched in October 2021 for commercial use in Japan.

Technology from the development of Panasonic’s ENE-FARM fuel cell cogeneration system was applied to the pure H2 fuel cell generator. By adopting the common stack unit, a key device of the fuel cell that is used in ENE-FARM, the new product offers stable performance of power generation and achieves electrical efficiency of 56%. The power output can be scaled up according to demand by connecting and controlling multiple generator units. In addition, by taking advantage of its lightweight and compact housing, this generator can be flexibly adapted to various installation conditions, including the rooftop and in narrow spaces.

Main features of the product include the 5-kW unit, which is scalable to increase power output by connecting multiple units. A single unit is suitable to meet the power demand of small-scale commercial facilities. Moreover, connecting and controlling multiple generator units can increase the power output according to demand. Furthermore, by connecting the product to a dedicated PC application, it allows the system to be remotely controlled to display the power output and conditions, turn the power generation on and off, and send error notifications. One PC allows the simultaneous connection of up to 10 units (50 kW). Further, by integrating 10 units into one level unit, MW-class power output is also possible.

By connecting a hot water storage unit with the product, heat generated from the fuel cell can be converted into hot water for use. The generator has achieved a total energy efficiency of 95% including the heat recovery, thereby allowing the effective use of energy without waste.

The use with a resistor unit and a startup power supply unit enables the product to generate power even during power outages. By connecting these units with the product, which is designed for power outages, users can continue to generate power and use up to 2.5 kW power for 120 hr, even during a power outage.

GREEN H2

Hydrogen Optimized gets grant to advance green H2 technology

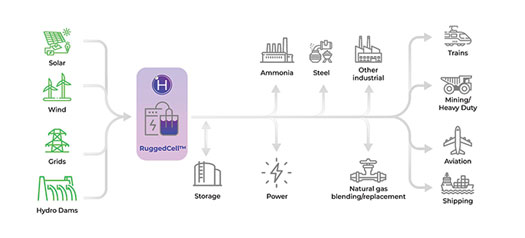

Hydrogen Optimized will receive $300,000 in funding from NGIF Industry Grants, a division of NGIF Capital Corp., to optimize the operation of its RuggedCell water electrolyzers, using an unstable electrical supply. The funding will be applied to a $900,000 project to demonstrate the company’s large-scale green H2 production technology under solar panel, simulated wind turbine and intermittent electrical grid conditions.

The funding will help Hydrogen Optimized obtain critical data on the performance of RuggedCell electrolyzers in conjunction with unstable renewable electricity sources and, ultimately, to achieve the company’s goal of driving down the cost of producing green H2 at scale. It will also support the work of Canada’s natural gas industry to reduce the carbon emissions intensity of natural gas. Green H2, when reacted with CO2, can produce renewable natural gas (RNG) through the methanation process.

Hydrogen Optimized’s RuggedCell water electrolyzers have a unipolar design that overcomes the historic difficulties of bipolar electrolyzers in effectively using all the available energy from intermittent electricity sources. This functionality makes the RuggedCell a solution for industrial end users to significantly reduce emissions from their processes using green H2. H2T