Articles

Scaling up green H2: Five critical steps to success

Special Focus: Pathways for Sustainable H2

N. MARTI, Emerson, Paris, France

Green H2 represents a viable path toward decarbonization and continues to attract global interest and investment. In the past few years, new policies have begun to pave the way for widespread adoption of green H2 as a sustainable energy carrier. Original equipment manufacturers (OEMs) are producing the electrolyzers, fuel cells and fueling equipment that will make adoption a reality. However, much work remains to be done: while today’s technologies are ready to safely produce, store, move and use green H2, manufacturing enough of it to build a global ecosystem remains a challenge.

Successfully scaling up production across the H2 value chain will require commitment from H2 providers and consumers alike. This article addresses five critical actions that H2 providers, particularly OEMs, must take for decarbonization through green H2 to become a reality.

Scale designs and capacity responsively to market demand. Today, fewer than 600 H2 fueling stations1 are in operation around the world and only 0.2 GW of green H2 is produced per year.2 By 2030, however, the global demand for green H2 is expected to reach 200 GW and an estimated 10,000 fueling stations will be in use. This rapid projected growth makes it a lucrative time to be in the green H2 industry; it also increases the difficulty of scaling designs and capacity to meet market demand.

To deliver, manufacturers must quickly scale up resources, factory extensions and procurement efficiency. To achieve this, OEMs are advised to work closely with an industry partner or partners with a proven history of successfully managing massive projects to completion. Such partners can meet OEMs at each stage of growth and reduce complexity by ensuring project and operational certainty.

Additionally, growing energy demands necessitate greater efficiency in the H2 production process. For proton exchange membrane (PEM) electrolyzers, reaching maximum efficiency is linked to accurately measuring the ratio of O2 and H2 production as the product gases exit the electrolyzer stack. To achieve this, consider using a backpressure hydraulic regulator loop with an electropneumatic PID (proportional integral derivative) controller.

Keep projects on time and on budget. Optimizing production is rarely easy even in well-established industries, let alone a still-developing one such as green H2. An obvious solution does not always exist, particularly for those new to the industry, and there is little room for guesswork. Once again, finding a management partner early on is recommended: an experienced project manager can lay the foundation for a successful startup and execution.

Digital tools can also be helpful in this regard. Dynamic simulation software, for example, can be used to create a digital twin of a physical environment, helping to optimize process and products before they are commissioned. Digital twin solutions allow OEMs to perform advanced testing for compatibility and other issues, as well as to train operators without affecting running processes. In this way, digital twins are able to reduce startup and commissioning time, improve project execution and mitigate risk.

Reduce cost and complexity of production and distribution. OEMs of all sizes and capabilities are emerging in the green H2 market. Some may have a unique design process that they understand in all aspects yet require assistance to develop and optimize current solutions; others may need help enacting a plan due to a lack of personnel, skills or resources to make production and distribution more efficient. OEMs experiencing these limitations can lower costs and simplify production and distribution by taking advantage of integrated solutions and educational resources.

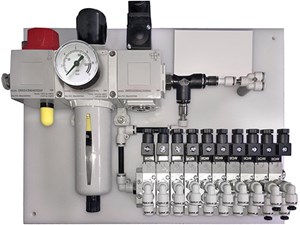

Integrated solutions. These are complete, ready-to-install, tested and certified solutions that simplify production processes, freeing up resources that OEMs can then put into technological development. Cabinets and panels are two excellent examples of integrated solutions that may be useful to OEMs in the green H2 industry. Cabinets (FIG. 1) house all control assemblies, including communication and power, inside an enclosure made of stainless steel or some other durable material, protecting the components within from extreme environments. Panel solutions connect components housed on a sub-plate assembly. Panels (FIG. 2) minimize system footprint and, as they make components easier to access, can help simplify diagnostics, maintenance and the replacement of parts. Cabinets and panels can be customized to exactly meet application requirements, taking the complexity out of ordering and assembling multiple components, and are good choices for H2 fueling stations.

Educational resources. These resources help OEMs better understand their design process and/or develop ways to make it more efficient. Some suppliers, for example, offer collaborative engineering workshops that not only operate as an extension of an OEM’s expertise, but also help build it. In these workshops, OEMs work with engineers and product experts to identify performance metrics and requirement definitions, create strategies that integrate findings, and learn about application-specific technology options and pilots. Educational resources help OEMs integrate new technologies (such as those that continue to emerge in the H2 field), design best practices regarding them, develop cost-saving strategies and accelerate their own technological developments.

Select scalable, advanced technology platforms. Advanced technology platforms provide data and insights that can empower informed decision-making throughout the H2 value chain. This, in turn, can improve operational safety and reliability, reduce emissions and optimize production and energy use.

Solutions can monitor the wear of pneumatic valves and actuators, detect decompressed air leaks in pneumatic systems and optimize compressed air consumption. Without these, operators have little to no information about the health and performance of their machines, resulting in expensive trial-and-error troubleshooting and higher-than-necessary downtime and carbon footprint.

Flexible and scalable software, when backed by suppliers with domain and application expertise, mitigates the risk of such situations. The software and expertise can also provide users with increased levels of control than would otherwise be obtainable, as well as relate critical device process and diagnostic data. Intelligent platforms with open-source software are particularly recommended: these can grow with each stage of development and help companies maintain a competitive edge while scaling up production.

Use the correct components for safe and reliable operation. In electrolyzers, fuel cells and fuel dispensing stations, H2 must be controlled safely, effectively and efficiently: H2 is a light, explosive element and represents a safety risk should leakage occur. Reliable pressure and flow control, up-to-date monitoring systems and robust components built for hazardous conditions (FIG. 3) are all necessary to keep people, equipment and operations safe.

To prevent leaks and explosions, electrolyzers and H2 dispensing stations should be installed in shelters with proper ventilation and protective systems, including relief valves and bursting disc systems as well as safety system shut-off valves (FIG. 4). Ultrasonic gas leak detection can also help protect these areas by constantly monitoring for the ultrasound generated by the release of pressurized gas. Fueling stations can utilize a programmable logic controller (PLC) with integrated edge gateway capabilities to further improve safety while guaranteeing gas purity and precise metering. PLCs such as these offer control by executing predictive analytics, including dispensing level, which in turn results in simplified supply chain logistics and a reduction in costs and unplanned downtime. Connecting reliable pressure transmitters and flowmeters to the gateway helps manage high pressure and flow applications more effectively, and also improves safety by producing real-time alerts.

Precise flow is also vital to H2 fueling stations (and also elsewhere in the H2 value chain). The H2 fueling ramp, in accordance with H2 fueling protocol SAE J2601, is handled by a pressure control valve and controlled via PID closed loop with a pressure transmitter and a Coriolis meter. Once an H2 fuel cell has been properly fueled, onboard fuel regulators can help maximize fuel efficiency by precisely controlling the flow of H2 to the fuel cell. It is important to choose a regulator that provides consistent pressure in the full range of operating conditions, such as the model illustrated in FIG. 5.

Finally, in cases where green H2 is injected into natural gas pipelines, a gas chromatograph can verify H2 purity to achieve an approved natural gas/H2 blend percentage, and injection accuracy can be determined by a flowmeter connected to a pressure control valve that is actuated with a PID controller. These combined measures will help prevent H2 from causing embrittlement and corrosion of the pipeline through which it flows.

It is highly recommended that OEMs source components like those mentioned above from suppliers that have comprehensive, specialized portfolios of such products. This allows OEMs to obtain field devices, valves, control systems, educational services and support from a single source, simplifying the supply chain and helping to meet production targets. Expert suppliers of this kind should also have the necessary knowledge to fulfill all necessary requirements and certifications: it is critical that suppliers and OEMs alike comply with all regulations regarding equipment installation, commissioning and operation.H2T

NOTES

a Emerson DeltaV™ Electronic Marshalling with CHARMs

b Emerson AVENTICS™ Air Prep Panel

c Emerson TESCOM™ VA and VG series valves

d Emerson TESCOM™ HV-3500 Series Hydrogen Onboard Regulator

LITERATURE CITED

1 “Record number of newly opened hydrogen refuelling stations in 2020,” FuelCellWorks News, February 17, 2021, online: https://fuelcellsworks.com/news/record-number-of-newly-opened-hydrogen-refuelling-stations-in-2020/

2 “Companies are developing over 200 GW of hydrogen electrolyzer projects globally, 85% of which are in Europe,” Aurora Energy Research, May 11, 2021, online: https://auroraer.com/media/companies-are-developing-over-200-gw-of-hydrogen-electrolyser-projects-globally-85-of-which-are-in-europe/

NICOLAS MARTI is the business development manager for EMEA—alternative fuel and combustion/fluid and motion control at Emerson. Marti joined Emerson in 2012 and specializes in H2 technology, including technologies for H2 filling stations and onboard H2/CNG applications. He received his education at the Paul Cézanne University Aix-Marseille III.