Articles

The future of aviation fuel: Are we on the right track?

Special Focus: Pathways for Sustainable H2

T. REINERTSEN, REINERTSEN New Energy AS, Trondheim, Norway

There is no doubt that the aviation industry has revolutionized travel by significantly reducing travel times between destinations. However, with increased air travel comes additional climate effects. For example, the global aviation sector emits about 1 Btpy of carbon dioxide (CO2). In addition, studies on condensation trails—those line-shaped clouds produced by aircraft engine exhaust—show that they are contributing to global warming.

The emissions from aviation represent about 3%–4% of the negative climate changes from human activities and are equivalent to the emissions from 500 MM fossil-fuel-powered cars.

The Clean Sky Joint Undertaking (CSJU) program (a public-private partnership between the European Commission and the European aeronautics industry) and other programs focus on efficiency improvements and the blending of new fuels such as biofuels, sustainable air fuel (SAF) and synthetic fuel. However, these fuels are expensive, and the implementation and utilization of these new fuels has been slow, as the availability of sustainable sources are limited—e.g., biofuels represent only approximately 1% of total air fuel. There seems to be a weak sense of urgency in the aviation industry for solving emissions challenges.

H2 as aviation fuel. In the future, global H2 production will increase, and H2 is expected to be available in sufficient volumes for the decarbonization of multiple sectors. H2 can be produced emissions-free in centralized natural gas plants, with carbon capture and storage (CCS) or in decentralized electrolyzer plants from water and renewable power.

Airbus and other aviation companies have started to develop large airplanes with liquid H2 as fuel. The plan is to store liquid H2 in the aircraft as fuel for modified jet engines. Other concepts are based on electric motors using batteries or fuel cells, but these are not technically feasible for large airplanes.

For a large airplane that needs more than 50,000 horsepower for liftoff, turbines fueled with H2 and/or ammonia seem to be the logical choice. The development of turbines that use H2 and ammonia as feedstock is ongoing in other sectors, as well, and these turbines are likely to be available in 3 yr–5 yr.

Numerous studies and projects performed by the author’s company and others demonstrate that H2 can be transported efficiently as compressed gas in pipelines, but not in tanks as liquefied or compressed H2. The transportation and storage of compressed H2 in tanks at 300 bars–700 bars are very inefficient and costly, while transportation and storage of liquid hydrogen at –253°C is very complex and is probably unrealistic for distribution to the world’s airports.

Is clean ammonia more realistic? H2 can be efficiently transported as compressed gas in pipelines or as ammonia by ships or trucks. The expanding pipeline infrastructure for H2 will facilitate the decarbonization of many sectors, but will not be sufficient to reach the world’s airports.

However, ammonia is a traded commodity, and the global ammonia infrastructure is well developed. Ammonia is far less explosive than H2, but it is toxic and must be handled safely by professionals. It is easy to transport in large quantities, and it exists in a liquid phase at atmospheric pressure and at –33°C or at room temperature and 10 barg pressure. A fleet of marine vessels already exists in global ammonia trading, transporting approximately 20 MMtpy of ammonia around the world, with many ports having installed ammonia receiving and storage facilities. The ammonia can then be shipped by trucks, pipelines or marine vessels to demand centers.

An alternative path for low-carbon aviation? Global ammonia distribution and storage infrastructure will be expanded, partly due to the demand for clean fuel from marine shipping. Presently, there is a strong trend for redesigning and modifying marine vessel engines to accommodate ammonia as fuel. Several companies are actively researching and developing technologies for this transition. Emissions from the shipping sector produce approximately 1 Btpy of CO2, about the same as from the aviation sector. To reduce the marine sector’s emissions to zero will require about 500 MMtpy of ammonia.

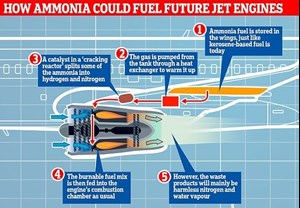

In 2021, a group led by Reaction Engines Ltd. presented a concept for ammonia-fueled jet engines (FIG. 1). Recently, NASA, Boeing and the University of Central Florida presented a program for the development of similar technologies. These concepts for the use of ammonia are based on loading ammonia into aircraft fuel tanks, cracking some of the ammonia into H2 and feeding the mixture to modified jet engines. The heat from the combustion is used for the cracking process.

For this to be a sustainable solution, the ammonia production must be clean, with little or zero greenhouse gas emissions. The primary goal is that no CO2 will be emitted from the production or from the use of ammonia in jet turbines. Nitrogen oxide (NOx) emissions from turbines must be controlled, and the safety aspects of toxic ammonia should be handled.

Large-scale, emissions-free ammonia production. Several large projects are emerging to produce low-carbon ammonia from natural gas. The high production capacity of such plants will typically be 10–100 times larger than from water/clean-power electrolyzer plants, and the production cost is less than half.

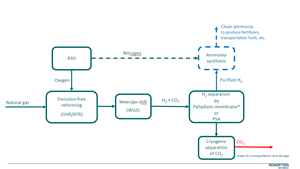

Large-scale ammonia synthesis, based on clean H2 from natural gas and nitrogen from an air separation unit (ASU), is available. The author’s company has developed an emissions-free proprietary processa to produce H2 and ammonia from natural gas with CCS (FIG. 2). The technology is based on proven processes such as autothermal reforming (ATR), fed by oxygen from an ASU, a palladium membrane or pressure swing adsorption (PSA) for H2 separation, and the cryogenic separation of CO2. This process solution has been further developed to an ultra-high CO2 capture rate of nearly 100% and is independent of clean power input. Additionally, the process can be tailor-made to fit a client’s project needs, and this shows that world-scale, emissions-free H2/ammonia plants can be built now.

Hopefully, the aviation industry will include clean ammonia in its development strategy as an alternative path for low-carbon aviation. It is urgent to address and solve the many challenges of reaching our global climate goals today. H2T

NOTES

a HyPro-Zero process

b HYDROGEN Mem-Tech AS

TORKILD REINERTSEN is the Chairman and Market Lead Hydrogen at REINERTSEN New Energy AS, which focuses on providing solutions and technologies for clean and efficient H2 and ammonia production with CCS, as well as complete value chains for H2, H2 carriers and clean fuels. Dr. Reinertsen is also the Founder and Owner of HYDROGEN Mem-Tech AS, which has developed an efficient palladium membrane technology for the separation of H2 from gas mixtures. Previously, Dr. Reinertsen was President of REINERTSEN AS, a company that has delivered engineering and EPC projects to oil and gas companies for more than 30 yr.