Articles

Reliable machinery enables cost-effective H2 liquefaction

Hydrogen Equipment and Services

L. MANN and D. PATRICK, Atlas Copco Gas and Process, San Luis Obispo, California; I. RICHARDSON, Plug Power, Colfax, Washington

The demand for hydrogen (H2) is expected to increase in the coming years, driven by the growth of H2 applications in mobility and investments in H2 infrastructure, such as the announced $8-B funding from the U.S. Department of Energy (DOE) for regional H2 hubs. In the past, the adoption of H2 technologies as an alternative to fossil fuels was hindered by the high cost of producing green H2 from renewable energy sources. However, the recent passage of the U.S. Inflation Reduction Act provides up to $3/kg production tax credit for green H2, making it cost competitive with the fossil-based gray H2 in all markets. This increased demand will require a reliable and efficient supply chain for green H2, including the production and transport of liquid H2.

H2 liquefaction. Liquefaction is a critical step in the H2 supply chain because it enables the transportation and storage of pure H2 in an energy-dense form. In addition, liquid H2 may be preferred over other mediums (e.g., gaseous H2, chemical carriers) due to the cost-effectiveness of transport and minimal infrastructure investment at the end-use site. Compared to gaseous H2, one liquid H2 tanker holds more H2 than eight standard tube trailers. Consequently, the H2 liquefaction capacity in the U.S. is expected to double in the next few years (FIG. 1).

Several cycles have been developed and commercialized for H2 liquefaction, including the Joule-Thomson, Brayton and Claude cycles. Each cycle has three main components: a precooling cycle, a cryogenic purification system and a liquefaction cycle.

The refrigerant used in the precooling and liquefaction cycles is carefully chosen to minimize the specific energy consumption of the processes. Nitrogen and H2 are the most used refrigerants for the precooling and liquefaction cycles, respectively, while helium is common in smaller-capacity liquefiers to reduce capital expenditure. Mixing these refrigerants with neon (e.g., Neon-H2, Neon-He mixtures) has also been proposed, but it is not yet commercially available. Once-through options may also be used, where a sacrificial refrigerant is vaporized to provide necessary precooling—e.g., using the available cold energy potential by vaporizing liquid natural gas (LNG) at an LNG import terminal to provide the precooling for H2 liquefaction.

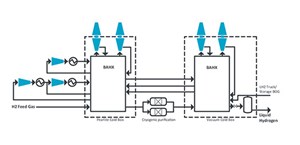

Liquefaction of green H2—H2 produced via electrolysis powered by wind and solar—necessitates operational versatility due to the variability of renewable energy production. Of the refrigeration cycles available, Brayton cycles for both precooling and liquefaction offer the unique advantage of utilizing solely gaseous refrigerants. This enables dynamic operation and control of the liquefier, allowing it to turn down and ramp up to match fluctuations in renewable energy prices and other dynamic factors. A schematic for dual-Brayton cycles for H2 liquefaction is depicted in FIG. 2. Critical to any refrigeration cycle are the operability and reliability of the machinery required to produce the needed cooling.

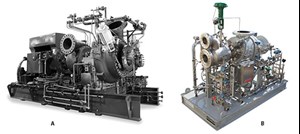

Machinery in liquefaction. The H2 liquefaction process relies heavily on machinery. Centrifugal compressors are employed in nitrogen precooling cycles, while reciprocating compressors are commonly used in the primary liquefaction cycle for positive displacement compression of the H2 refrigerant. Cryogenic turboexpanders, which play a central role in refrigeration, are utilized in precooling and primary liquefaction cycles.

A turboexpander is a radial inflow turbine that expands a gas in a nearly isentropic process to produce refrigeration and shaft power. A H2 turboexpander design can be challenging due to the low mole weight and high enthalpy drop of H2, resulting in machines with high impeller tip speeds that often require multiple stages to expand the gas effectively. Recovering the turboexpander shaft power to generate electricity or reduce the compressor duty can improve cycle performance. Early liquefier designs dissipated the turboexpander shaft power in the form of a braking device, but the ability to incorporate energy recovery can improve plant-specific energy consumption. Oil-free designs are the best practice for all machinery to handle the deep cryogenic temperatures and prevent any possibility of oil contamination of the heat exchanger. Turboexpanders with magnetic bearings enable an oil-free, hermetically sealed system with no loss or venting of the refrigerant (FIG. 3).

Machinery reliability. Reliability is an important factor to consider when evaluating process designs and selecting machinery. Reliability is the equipment’s ability to perform its required function under given conditions for a specified time interval. Decades of experience operating turbomachinery in critical processes have led to the development of industry standards, such as API 617. This standard—which covers the minimum requirements for integrally geared centrifugal compressors and turboexpanders—specifies a service life of 20 yr and continuous operation of 5 yr. Decades of operating experience in demanding services have demonstrated that turbomachines such as centrifugal compressors have an availability up to 99.7%.

Many factors must be considered by the original equipment manufacturer to ensure the reliability of turbomachinery. From the engineering and design phase through manufacturing and testing, each phase requires meticulous attention to detail to ensure a long-lasting product. In design, mechanical analyses—such as computational fluid dynamics and finite element analysis—evaluate impeller stress and natural frequencies to avoid resonance modes during operation. Rotordynamic stability is another critical factor to evaluate to avoid rotor instabilities, which can lead to mechanical failures. Simulation results require validation and testing, including vibration and mechanical run testing.

To maximize the reliability of turbomachinery, it is also important for the owner-operator to implement proper maintenance practices and follow the manufacturer's recommendations. This can include regular inspections and replacements of worn parts and proper equipment operation and control. By considering reliability at every stage of the equipment lifecycle and implementing best practices for maintenance and operation, the lifespan and performance of turbomachinery can be maximized.

Impact of turbomachinery reliability on liquefier economics. Thanks to economies of scale, a H2 liquefier’s capital cost improves relative to increases in size, meaning larger liquefiers can drive down the costs of producing liquid H2. Additionally, larger liquefiers can improve plant performance and reliability due to the scalability of turbomachinery, which keeps the overall unit count to a minimum. This phenomenon is especially apparent when comparing turboexpanders, magnetic bearings and other oil-free technologies, such as static or dynamic gas-bearing turboexpanders. Gas-bearing units are limited in capacity and may require additional units as plants scale. As a result, they do not offer the same scalability and reliability advantages seen with magnetic bearing designs.

Machinery reliability is critical to plant throughput because an outage of the liquefier may lead to a production shutdown if other storage means are unavailable. This can result in lost revenue and an inability to meet customer supply guarantees. Companies looking to enter the H2 industry must have confidence in their ability to source H2 consistently. Furthermore, for the plant’s longevity, it is important to minimize unexpected shutdowns, as frequent thermal cycles on the equipment can introduce thermal stresses that can lead to failures in cryogenic equipment.

While unplanned shutdowns are never welcome, planned maintenance is always required. The most maintenance-intensive equipment in a H2 liquefier is the reciprocating compressor, which requires a planned shutdown of up to 2 wk/yr. In the case of the reciprocating compressor, running two 50% capacity compressors instead of one 100% capacity compressor allows for continued partial production during planned maintenance. Such turndown in capacity and continuous operation is enabled by the turbomachinery's reliability and longer maintenance intervals, which typically only require turnaround service every 5 yr.

Takeaway. The growth in demand for H2 as a cleaner fuel source drives the need for a robust and efficient supply chain for green H2. H2 liquefaction plays a critical role in the supply chain by enabling the mass transportation and storage of H2 in an energy-dense form. The Brayton cycle offers operational versatility and dynamic control, and machineries such as centrifugal compressors, reciprocating compressors and cryogenic turboexpanders are critical components in the process. The reliability of these machinery systems is crucial to ensure the success of H2 liquefiers, which are pivotal to driving down H2 costs for widespread adoption. Adherence to industry standards and best practices in design, manufacturing, testing and maintenance throughout the machinery's lifecycle is vital to optimize the reliability and performance of the equipment.H2T

About the authors

LOUIS MANN is the marketing and R&D Manager for Atlas Copco Gas and Process Division, California, U.S. Mann joined Atlas Copco in 2008, holding roles in package engineering, applications, engineering management and R&D. He earned a BS degree in mechanical engineering from California Polytechnic State University, San Luis Obispo, and he is a registered professional engineer in California.

DANIEL PATRICK is the H2 and CCUS application Manager for Atlas Copco Mafi-Trench Company (part of Atlas Copco Gas and Process). Patrick joined Atlas Copco in 2012 and has worked on the applications and project engineering teams. Before moving to his current role, he served as senior team lead and applications lead for new energy and H2. Patrick earned a BS degree in mechanical engineering from California Polytechnic State University, San Luis Obispo.

IAN RICHARDSON is the H2 product development and R&D Manager for Plug Power’s H2 liquefaction program. He is an expert in cryogenic systems and green H2 technologies. Prior to joining Plug, Richardson co-founded a startup commercializing lightweight liquid H2 fuel tanks and the associated fueling systems to support the energy transition in the aerospace sector. Richardson earned his PhD from Washington State University focusing on cryogenic fluid mixtures for NASA.