Articles

Digital real-time H2 ecosystem management

Digital Technologies

K. FINNAN, Yokogawa, Hartford, Connecticut

While other industries are amid digital transformations, the hydrogen (H2) ecosystem is a greenfield that can begin operations with transformative technologies in place. They empower people, optimize processes and automate systems to enhance business performance across the enterprise.

A H2 hub can start up with digital, real-time management using contemporary technologies such as advanced analytics, advanced process control (APC), artificial intelligence (AI), the Cloud, connected workforce, digital twins, Edge devices, 5G communications, the Internet of Things (IoT), machine learning (ML), robotics and virtual reality. Digital twins can begin even earlier at the inception of the facility design process and sustain themselves through operation and maintenance. Any brownfield assets will only be included if the H2 ecosystem extends to existing resources on the grid. Of course, the brownfields would be ripe for digital transformations.

The completely digital environment uses an enterprise-wide, collaborative information platform. Based in the Cloud, on-premises or a combination of the two, this environment enables centralized management and allows rapid decision-making by integrating the handling of large amounts of data from the widely varying types of equipment and process units in use throughout the ecosystem. Broad scalability enables expansion within the H2 hub, consumer base and grid assets.

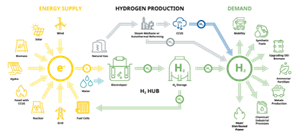

The following examples describe how some transformative technologies can make H2 optimized, integrated, autonomous and sustainable (FIG. 1).

DIGITAL TWIN EXAMPLE: GAS TURBINE USING H2 ENRICHED FUEL

A greenfield operation such as a H2 hub will incorporate various digital twins, which optimize assets, operations and safety. According to a subsidiary of the author’s company, leaders in the power generation industry hail gas turbines as the turbomachinery of excellence. Using natural gas instead of other fossil fuels has been shown to reduce carbon dioxide (CO2) emissions by 20%. Using H2 in gas-fueled turbines has proven to be a promising solution to reduce CO2 emissions even more.

However, switching to H2-natural gas fuel blends has some drawbacks due to differences in heating efficiency between H2 and natural gas. Additionally, the CO2 intensity reductions with an increase of H2 are constrained by the size of existing facilities. Finally, H2 in the gas turbine fuel gas lowers the exhaust temperature, which could impact the performance of the combined cycle systems. By deploying a digital twin, leading gas turbine manufacturers can manage these issues to significantly curb CO2 emissions while most effectively integrating H2 into the fuel mixture.

Optimizing steam methane reformers (SMRs) and other fired assets. The operation of combustion assets, such as SMRs, is expected to continue through 2050, focusing on minimizing emissions and optimizing operations. Keeping emissions as low as possible simplifies the carbon capture processes required for net zero.

A benefit of modern process control systems is their support for APC and holistic methods targeted to specific assets. Holistic methodologies have already been proven to optimize the operations of assets such as SMRs. These include improving safety; increasing asset and catalyst life spans, fuel efficiency and productivity; minimizing downtime and nitrous oxide and CO2 emissions.

Overall energy management. Digital greenfields such as H2 hubs can also immediately exploit the energy management technologies other operations have implemented in response to the energy transition. A single energy management system includes integrated monitoring, scheduling and real-time optimization technology for energy systems. It provides insights for minimal emissions and cost-effective energy production, distribution, scheduling and trading.

The energy management system combines first principles digital twins and multi-period optimization to proactively schedule and operate at the lowest emissions and economic cost, enabling real-time actions in an open or closed loop system to deliver fast and accurate operational decisions. It scales from site-wide to area-wide under a virtual power plant scope spanning several geographically distributed assets. These capabilities maintain the license to operate for the emerging H2 ecosystem enterprise.

Managing distributed energy resources on the grid. Unlike H2 hubs, electrical power generation and distribution assets often combine greenfields and brownfields, the latter of which would need measurement and control system updates and digital transformations. Today, many operators manage multiple power generation technologies, often over widely distributed geographical areas. It is not unusual for an enterprise to use intermittent sources (e.g., wind and solar) and traditional fossil fuel-powered generation. Managing the distributed resources quickly becomes complex for an enterprise that combines a H2 hub with existing power generation and grid assets.

Operators of traditional power generation find management of renewable intermittencies throughout the grid to be a new, unfamiliar issue. Those managing solar generation along with wind note that there could rapidly be a significant loss of output, affecting energy regionally and power quality locally. A solar photovoltaic (PV) system can transition from full power to 30% output in a matter of seconds.

The key emerging technologies to optimally manage such resources include distributed energy resource management systems (DERMS), microgrid control and renewable power plant control. A DERMS manages renewable energy assets, coordinating distributed resources such as power generation and storage alongside traditional grid components. The microgrid controller locally manages renewable energy assets and coordinates with traditional grid components. The renewable power plant controller can maximize the efficiency and production of any combination of small-scale and utility-scale renewable energy assets, such as those in a H2 hub.

A DERMS helps utilities control the expansion of renewable energy assets, including those throughout a H2 hub, plus batteries and electric vehicles. Operators can balance simultaneous resource, load, demand and network constraints while enabling a 100% renewable grid.

A DERMS can remotely communicate with and control a combination of distributed energy resources (DERs) quickly and securely. It compensates for load changes by coordinating utility-owned and customer-owned assets, such as solar panels, across the grid.

The DERMS mitigates intermittency and coordination challenges by optimizing the energy mix of all DERs under its purview. It also perceives the system as a whole. It identifies opportunities to shape, shift and balance power across the whole system rather than solely at the point of generation or demand.

Today’s microgrid controller is a hardware-agnostic software application that works with existing assets to improve equipment efficiency, thus reducing or eliminating the need for expensive infrastructure upgrades. Its primary task is to maintain reliable, renewable power during any type of grid event—expected or unexpected—without sacrificing power quality or consistency.

The renewable power plant controller maximizes return on investment (ROI) by unifying solar, wind and energy storage assets under a single platform. It independently controls real and reactive power as measured at the point of interconnection (POI) to support participation in energy markets and ancillary service products. It also integrates and autonomously adjusts to demand response program and peak-load energy shifting parameters.

Today’s DERMS are scalable and allow for physically and financially phased integration, thus, simplifying the integration of new assets such as H2 hubs. Ultimately, they support the energy transition to fully sustainable power generation.

H2 ECOSYSTEM AS AN AUTONOMOUS, SUSTAINABLE OPERATION

Today’s new technologies enable unprecedented levels of automation, including remote and unmanned operations. A facility might entirely automate its operations, maintenance and incident management to put people out of harm's way. Similar to greenfields, H2 hubs are perfectly positioned for autonomous operations from their inception.

An autonomous operation (industrial autonomy) is where plant assets and operations possess learning and adaptive capabilities that enable responses with minimal human interaction, empowering operators to perform higher-level optimization tasks.

An autonomous H2 ecosystem employs sensing and digital infrastructure that spans the entire operation and integrates data, smart devices at the edge and robust hardware and software that deliver the necessary flexibility, adaptability and resilience levels. The autonomous H2 enterprise is optimized from the start and can learn and adapt to changing market conditions.

A system of systems. A system of systems is an emerging concept representing the ultimate destination for the autonomous operations journey. The H2 ecosystem illustrates a future symbiosis between industry and society in which all entities function autonomously yet in a coordinated manner.

In a system of systems, formerly disparate components will benefit from compatibility in terms of data, networking and protocols, and they will be autonomous. Using technologies such as AI and digital twins, individual systems can learn from each other without human intervention and rapidly adapt to market dynamics and disruptions. That allows them to advance continually and makes them inherently sustainable.

According to the system of systems concept, multiple, independently operating and managed systems coordinate to achieve a purpose that extends well beyond the capabilities of any single system. The H2 hubs, grids and consumer applications that comprise the H2 ecosystem can be part of a world in which entire societies function as systems of systems.

Takeaway. The H2 ecosystem is arriving on the scene at a favorable time regarding available technologies. For many companies, digital transformation empowers people, optimizes processes and automates systems to optimize business performance. While other industries are amid digital transformations, H2 hubs are greenfields, which can begin operations with transformative technologies in place.

Additionally, transformative technologies provide the benefit of scalability. Enterprises can think big but start small with infrastructure components and scale up to span entire ecosystems. They can make H2 sustainable, optimized, integrated and autonomous. The autonomous operations will eventually enable entire societies to operate as systems of systems, where multiple, formerly independently operating and managed systems coordinate to achieve a purpose that extends well beyond the capabilities of any single system.

About the author

KEVIN FINNAN is a Market Intelligence and Strategy Advisor at Yokogawa. He was previously an independent consultant, Vice President of Marketing for CSE-Semaphore and Director of Marketing at Bristol Babcock. Finnan has more than 30 yr of experience in various vertical markets and has launched more than 40 products in automation and measurement technologies.