Articles

The hydrogen economy

Viewpoint

B. OFORI, Emerson, Marshalltown, Iowa

In 1969, Apollo 11 allowed humankind to take their first steps on the moon. Unknown to many, hydrogen (H2) made that mission possible through the use of H2 fuel cells to supply electricity and water for the capsule, along with liquid H2 to fuel the rockets.

More than 50 yr later, a confluence of events is enabling H2 to play a significant role in the world’s energy policy by decarbonizing supply sources and addressing the pressing challenges of global warming. This article discusses the benefits and challenges posed by H2, and the steps governments and companies are taking to bring the H2 economy to fruition.

The benefits of H2. H2 provides viable solutions to a number of challenges that face the world today. Specific advantages include:

- H2 is well-understood and already employed in many industries today. Companies are very familiar with the sealing, metallurgy and process requirements of the gas.

- H2 fuel cells generate electricity and emit only water.

- H2 offers an economic means of storing energy and leveling the energy production of variable energy sources like wind and solar. During times of excess energy, power can be used to power electrolyzers, which generate H2 for storage in fuel cells.

- H2 provides enough energy density to handle applications that are difficult to address with battery storage. H2 fuel cell electric vehicles are much better suited to handle long distance road transport, heavy-duty trucking and even commercial aircraft.

- Large amounts of H2 are already being used by the ammonia, methanol, steel and refining industries. The bulk of this H2 is synthesized from natural gas, producing significant greenhouse gas (GHG) emissions. However, if this H2 could be produced by electrolyzers or created from natural gas employing carbon capture technologies, the net carbon emissions reduction would be enormous, and the processes themselves would require minimal modification.

- The simple act of blending clean H2 with natural gas provides an easy and immediate method of reducing GHG emissions in existing equipment.

H2’s challenges. H2 as a material poses challenges associated with leak avoidance and metallurgical effects. The molecule itself is very small and tends to pass through many metals and sealing compounds. Pressurized H2 can also embrittle some metals, so proper material selection is important. Fortunately, H2 is commonly used in many industrial processes, so its handling is well understood, and many options are available for H2 instrumentation and control valves.

Clean H2’s chief problem has been its cost because it has historically been much cheaper to generate H2 from hydrocarbons, stymieing the growth of alternate green options. This cost differential has been the biggest reason a green H2 economy has been slow to develop.

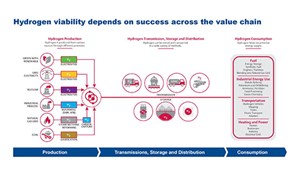

A changing environment. The worldwide focus on GHG emissions and clean energy alternatives has placed a bright spotlight on H2. Numerous governments around the globe have earmarked significant research sums to optimize H2 technologies and lower costs. Money is also being spent on building the infrastructure necessary to safely generate, transport and utilize H2 in world marketplaces. FIG. 1 provides a good overview of the effort required to make a H2 economy a reality. As the figure shows, advancements will occur at each link in the value chain.

Recently, the Southern California Gas Company (SoCalGas) created a 2,000-ft2 microgrid demonstration home designed to use clean H2 24/7/365. Solar cells power electrolyzers to create and store H2 in fuel cells during the day, which provide electricity and heating for the home. Details on the project can be found in literature.1

Ongoing efforts. While global governments have been directing money and resources to speed adoption, the private sector is also working hard to make the H2 economy a reality. Advances in electrolyzer design and fuel cell technology continue to improve the efficiency and reduce the cost of green H2 production.

Control innovations and equipment designs help optimize H2 production, storage and transport, and utilize that H2 in ways that significantly reduce industry’s carbon footprint. Companies are moving beyond words and goals to improve H2 production by taking advantage of incentives for targeted industries, financially supporting pivotal organizations and supplying equipment that enables the latest technologies to be efficiently utilized.

The most productive efforts will include a mix of short- and long-term strategies. Short-term changes, like green H2/natural gas blending, offer immediate decarbonization benefits that can be implemented now. Longer term improvements in green H2 generation and H2 storage/transport infrastructure will enable significant GHG reduction in the future.

It has been a long time since the Apollo missions led the way, but after many fits and starts, the H2 economy is coming into its own.H2T

LITERATURE CITED

1 “Blended hydrogen project: Emerson technologies help SoCalGas deliver clean energy for [H2] innovation experience,” Emerson, online: socalgas-delivers-clean-energy-for-[h2]-innovation-experience-en-8618038.pdf (emerson.com)

ABOUT THE AUTHOR

BRUCE OFORI is the Sales Development Manager for ESG at Emerson for its flow controls products. He works with global customers to help them achieve their emissions and energy reduction targets. Ofori is a graduate of the Kwame Nkrumah University of Science and Technology in Ghana with a BS degree in chemical engineering, and he obtained his MS degree in petroleum and gas engineering from the University of Salford in Manchester, England and from Missouri University of Science and Technology, Rolla, Missouri, U.S.