Articles

Producing green H2 on a gigawatt scale

Editorial Comment

TYLER CAMPBELL, Managing Editor

Scaling electrolyzer technologies is an essential ingredient to cleaning up the world’s energy mix. Green hydrogen (H2) production must be scaled up, but electrolyzer production must keep up with the rising demand for clean H2. Electrolyzers have proven more efficient at producing H2 than thermochemical and photocatalytic methods, but this will not matter if the supply does not keep up with demand. Proton exchange membrane (PEM) electrolyzers use iridium, which is expensive, but research is being conducted to use alternative materials, such as cobalt.

According to Future Market Insights, the U.S. electrolyzer market size is projected to expand at a compound annual growth rate of 23.8% from 2023 to 2033, and PEM electrolyzers are estimated to contribute to more than 45% of the market value share.1 Precious metals, such as iridium, are not feasible to scale with the growing prominence of the technology; thus, alternative catalysts are crucial. Another option is solid oxide electrolyzer cells (SOEC), which do not require precious metals as catalysts.

Regardless, a massive amount of electrolyzers must be manufactured. Topsoe is constructing an industrial-scale SOEC manufacturing facility with an initial 500-megawatts (MW) production capacity. Nel plans to build an automated gigawatt (GW)-electrolyzer manufacturing facility in Michigan, U.S. The facility aims to have a production capacity of up to 4 GW of alkaline and PEM electrolyzers. The company is also planning to build a new fully automated production line at its facility in Norway. Larsen & Toubro plans to set up a GW-scale manufacturing facility for electrolyzers based on McPhy’s alkaline electrolyzer in India.

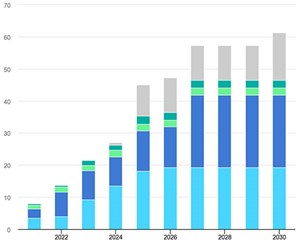

According to the International Energy Agency (IEA), the total installed electrolysis capacity is set to reach 5.5 GW by the end of 2023 and 134 GW−240 GW by 2030 if all current projects are realized.2 However, more than 700-GW electrolyzer capacity is required to meet 2030 targets (FIG. 1). Therefore, much progress is still needed.

LITERATURE CITED

1 Future Market Insights, “USA hydrogen electrolyzer market outlook (2023 to 2033),” April 2023, online: https://www.futuremarketinsights.com/reports/usa-hydrogen-electrolyzer-market

2 IEA, “Electrolysers,” September 2022, online: https://www.iea.org/reports/electrolysers