Articles

Challenges in making green H2 a reality at mass scale

Blue/Green H2 Production

A. RASTOGI, Fluor Daniel India Private Ltd., New Delhi, India

Green hydrogen (H2) has been in the news often lately and is the trendiest clean energy source globally. Many countries are focusing on renewable energy sources and green H2 in a bid to cut carbon emissions worldwide to meet net-zero by 2050. Presently, few green H2 plants are in operation or are at the pre-commercial phase with limited electrolyzer capacity (typically < 50 MW). Their contribution is less than 1% of the total H2 produced globally—most H2 is produced from unabated fossil fuels, with deleterious effects on the climate. Global H2 production is equivalent to about 3% of global final energy demand with a negligible contribution of green H2. The green H2 sector is at the nascent stage and must ramp up to mass scale production. However, a few barriers, such as high capital and operational expenditures (CAPEX and OPEX) and inefficiencies, must be conquered before mass scale production. This article addresses the challenges involved in the production of green H2 at a large scale.

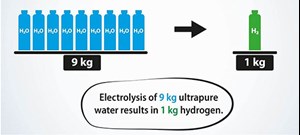

Green H2 overview. Green H2 is produced by water electrolysis to split water (H2O) into H2 and oxygen (FIG. 1). Electricity from renewable energy sources—such as solar, hydro or wind power—is used in this production method, emitting zero-carbon dioxide (CO2) throughout the entire production process.

Challenges in the mass production of green H2. Hurdles to be overcome include:

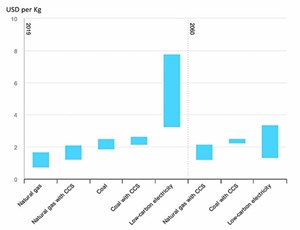

- Green H2 production involves significant CAPEX and OPEX, which makes it presently commercially unviable compared to other H2 production technologies (FIG. 2). However, technology experts believes that costs will lower in the future due to decreasing renewable energy prices, and the improved efficiency and reduced cost of electrolyzers.

- Current electrolyzers used in green H2 production have very low efficiency. About 52.5 kWhr of energy are required to produce a kilogram (kg) of H2, which holds 39.4 kWhr of energy. Electrolyzer manufacturers are advancing their technology to increase efficiency as high as 95%. This could lower green H2 costs to an estimated $1.50/kg in the future.1

- Green H2 production uses electricity from renewable sources like solar, wind and hydro, which have availability constraints. Renewable power is not available 24/7, making it difficult to operate electrolyzers at baseload capacity all the time. Large battery storage is required to continuously supply power for the non-stop production of H2.

- One m2 of area produces 5 kWhr of solar energy and 52.5 kWhr of electricity are required to produce 1 kg of H2. Approximately 10 m2 of area are required to produce 1 kg of H2. Scaling H2 production requires more area for increased solar power production.2

- In addition to electrolyzers, the balance of plant also utilizes renewable energy ranging from 5 kWhr–15 kWhr/kg of H2. The overall renewable power consumption will further increase with the scaling of production.

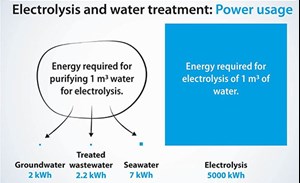

- Nine kg of ultrapure water is required to produce 1 kg of H2. This is very high-purity deionized water that requires a special water treatment system. An existing water treatment system cannot be used. This would further increase CAPEX and OPEX costs (FIGS. 3 and 4).

- The average life of electrolyzer modules is 80,000 hr (10 yr), which is 1/3rd of the design life of a H2 production facility (typically 30 yr). This increases OPEX costs. This also leads to a longer turnaround period due to the replacement of an electrolyzer every 10 yr.3

- H2 cars are less efficient than battery-powered cars according to a study by car manufacturer Volkswagen—a H2 car consumes two to three times more electricity for the same distance than a battery-powered car. According to the study leader Dietmar Voggenreiter, “No sustainable economy can afford to use twice the amount of renewable energy to drive with fuel cell passenger cars rather than battery-powered vehicles.”4

Takeaway. Green H2 is a clean renewable fuel that releases no greenhouse gases (GHG). However, its viability is subject to its cost and efficiency. High CAPEX and OPEX cost—including the high cost of renewable energy—make green H2 2–3 times more expensive than H2 produced using other technologies. Also, the present low efficiency of green H2 technology makes it less favorable compared to other fuels and electricity. These factors will further ramp up the scaling of a H2 production facility. In the current scenario, it would be beneficial to use renewable power directly rather than using it (52.5 kWhr) to produce 1 kg of H2, which holds 39.4 kWhr of energy. Presently, green H2 is not yet commercially attractive, but advanced technologies, improved efficiency and decreasing renewable energy prices will definitely make it a commercially viable clean energy source in the future.H2T

LITERATURE CITED

1 Blain, L., “Record-breaking hydrogen electrolyzer claims 95% efficiency,” New Atlas, March 2022, online: https://newatlas.com/energy/hysata-efficient-H2-electrolysis/

2 “Solar irradiance—Solar irradiance and solar irradiation,” Alternative Energy Tutorials, online: https://www.alternative-energy-tutorials.com/solar-power/solar-irradiance.html

3 Plug, “Plug electrolyzer stack reliability,” online: https://resources.plugpower.com/electrolyzer-hydrogen-production/plug-electrolyzer-stack-reliability

4 VW Newsroom, “Battery or fuel cell, that is the question,” March 2020, online: https://www.volkswagen-newsroom.com/en/stories/battery-or-fuel-cell-that-is-the-question-5868

About the author

ANUJ RASTOGI is a Mechanical Engineer with Fluor Daniel India Private Ltd. New Delhi and has been with the company for 12 yr. He has more than 18 yr of experience in packaged equipment and holds a B.Eng degree in mechanical engineering. The author can be reached at anuj.rastogi@fluor.com.