Articles

H2Tech: Tech Spotlight

T. CAMPBELL, Managing Editor

H2 EQUIPMENT

Fives launches its first 100% hydrogen (H2) duct burner

Fives has launched its first 100% H2 duct burner. The Hy-Ductflam™ is a step toward the decarbonization of heating and drying processes globally because H2 emits zero carbon dioxide (CO2) when burned. Designed for new installations or to replace standard duct burners, Fives’ solution can be easily implemented by manufacturers with limited process modifications.

Manufacturers are looking for alternatives to reduce their carbon and environmental footprint, and H2 is one solution. Fives’ Hy-Ductflam enables customers to easily switch fuels from 100% natural gas to 100% H2 without changing the equipment. For example, using the technology set on 100% H2, a paper plant will emit 170 kilograms (kg) less CO2/t of paper produced, reducing its carbon footprint by about two-thirds.

Providing high efficiency and mechanical reliability, the Hy-Ductflam is suitable for any duct configuration. This means it can be installed in new installations and replace standard duct burners, limiting costs for manufacturers. This technology is mainly dedicated to drying applications in ceramic, minerals and pulp, but could be extended to other applications such as heat recovery boilers. Technical features include:

- Hot gas generators and turbine/motor post-firing for drying applications

- Suitable for any duct configuration

- Going from 100% natural gas to 100% H2

- High turndown (1:10 or higher).

Smoltek wins patent for electro-catalyst for electrolyzers

Smoltek has been awarded a new patent in a new patent family the company calls Electro Catalyst Support, which is targeted toward green H2 production. The innovation displays how carbon nanofibers can support the iridium catalyst load in a proton exchange membrane (PEM) electrolyzer. This technology also increases the output per area of the cell.

The Electro Catalyst Support patent family covers an electrolyzer and method for producing a catalyst supported on a nanostructure. The innovation relates to devices used in electrolysis, particularly for water electrolysis. It provides a means of converting excess electrical energy from intermittent energy sources—such as wind, solar power and chemical energy—for storage and later use.

The patent family contains an electrolyzer containing elongated, vertically oriented nanostructures that connect the catalyst particles on the protected nanostructure and in contact with the membrane, providing conducting paths for ions and electrons. The technology is suitable for nanostructures that are at least partially covered by a protective layer designed to increase resistance to corrosion, enabling them to be used on the anode side of a PEM electrolyzer.

H2 STORAGE AND TRANSPORTATION APPLICATIONS

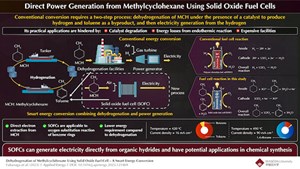

Direct power generation from methylcyclohexane using solid oxide fuel cells

Methylcyclohexane (MCH) is promising as a H2 carrier that can safely and efficiently transport and store H2. However, the dehydrogenation process using catalysts presents issues due to its durability and significant energy loss. Japanese researchers have succeeded in using solid oxide fuel cells (SOFCs) to generate electricity directly from methylcyclohexane and recover toluene for reuse. This research is expected to reduce energy requirements and explore new chemical synthesis by fuel cells.

MCH, a type of organic hydride, is expected to be an excellent H2 carrier because it remains liquid at room temperature, is easy to transport, has low toxicity and has a higher H2 density than high-pressure H2. Dehydrogenation—the process of removing H2 atoms from molecules—in the presence of a catalyst yields H2 and the byproduct toluene, which can generate electricity to produce CO2-free power. However, the dehydrogenation reaction is endothermic, and energy loss and the facilities required for the reaction present challenges.

Recently, a team of researchers from Japan, led by Professor Akihiko Fukunaga from the Department of Applied Chemistry at Waseda University, generated electricity directly from MCH using SOFC.

The research team tried to perform two processes simultaneously in a fuel cell: dehydrogenation from organic hydrides, which is an endothermic reaction, and electricity generation, which is an exothermic reaction. To achieve this, they used an anode-supported SOFC with a higher operating temperature than a polymer electrolyte fuel cell. They operated it at a temperature that did not allow pyrolysis of organic hydrides and under conditions that prevented carbon deposition at the electrodes.

The production ratio of toluene to benzene was 94:6. This achievement demonstrated the possibility of generating electricity without dehydrogenation facilities that were conventionally required and using less energy than that required for dehydrogenation reactions using catalysts.

These results indicate that the MHC reacts with the conducting oxygen ions in the SOFC to generate electricity successfully. Thus, power can be generated directly from MHC, and the energy required for direct power generation is less than that required for the conventional catalyst-assisted dehydrogenation reaction of MCH.

CB&I receives approval for liquid H2 cargo containment system for gas carriers

CB&I, McDermott's storage business, has received Approval in Principle (AiP) for its liquid H2 (LH2) cargo containment system design from DNV, a leading classification society for shipping. CB&I collaborated with Shell International Trading and Shipping Co. to provide safe LH2 shipping solutions that enable H2 energy supply chains.

The AiP confirms that the containment system aligns with applicable safety standards. These include class rules, the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and the Interim Recommendations for Carriage of Liquefied H2 in Bulk, Resolution MSC.420(97), issued by the International Maritime Organization (IMO). A hazard identification (HAZID) risk assessment was carried out as an integral part of the AiP process to ensure that the hazards and uncertainties associated with the containment system were identified and handled appropriately.

The containment system design is based on CB&I's proven vacuum-insulated spherical technology for onshore LH2 storage. CB&I has designed and constructed more than 130 large, field-erected LH2 storage tanks worldwide over the past 60 yr. This experience provides the energy transition industry with an economical, low-risk shipping solution with the best available time to market.

CB&I expects the design to be scalable to 40,000 m3 per tank, with estimated boiloff rates of < 0.1%/d for small tanks and < 0.05%/d for large tanks. The combined cargo containment system and hull design aim to address the energy density challenge, benefitting from LH2's properties and achieving more energy onboard. The cargo containment system was integrated into a concept vessel design developed by Houlder, which includes a hull optimized for the low-density cargo around the three large tanks.

NETL develops coating technology to protect pipelines from corrosion

An invention reported by researchers from NETL can help protect against corrosion in natural gas, H2 and CO2 pipelines. Pipeline corrosion can cause catastrophic failure events, such as explosions and emissions of environmentally damaging substances like methane. The innovation is a new self-healing cold spray coating for internal pipeline corrosion protection.

Traditional approaches to fighting pipeline corrosion include using inhibitors or organic coatings such as fusion-bonded epoxy and polyurethane. Injecting inhibitors in natural gas or CO2 pipelines is challenging due to the difficulty of transporting the inhibitors along the pipelines. The main disadvantage of using organic coatings for internal pipeline protection is their poor abrasion resistance and that they can form a corrosion focal point.

A sacrificial coating, or anode, undergoes oxidation more than the metal surface it protects, effectively stopping oxidation on the metal. However, the existing sacrificial coatings tend to dissolve too fast in natural gas pipelines.

Cold spray is a high-energy, solid-state coating and powder consolidation process for applying metals, metal alloys and metal blends for numerous applications. Cold spray uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic nozzle for particle adhesion. The coating can be applied to the interior of a pipeline by using a robotic cold spray device attached to a pipeline pig.

Some of the features and advantages of the new zinc-rich coating approach compared to existing approaches include its ability to:

- Remain stable regardless of temperature/pressure changes in the service environment

- Avoid defects during cold spray deposition, resulting in extended life

- Self-heal when damaged by forming protective corrosion products

- Prevent periodic application (long life)

- Be used as a structural material to repair used/damaged pipelines.

H2 PRODUCTION

TFP introduces manufacturing technology to accelerate green H2 production

TFP Hydrogen has unveiled its latest technological breakthrough, the TFP Hydrogen modular production unit (MPU). This innovative solution represents a significant stride towards enabling rapid scalability for PEM electrolyzer manufacturing.

Leveraging TFP Hydrogen’s proprietary coating technology, the MPU is strategically designed to operate near customers and component suppliers, streamlining the supply chain for PEM electrolyzer manufacturers. By shortening the supply chain and optimizing logistics, the MPU significantly augments response rates while ensuring uninterrupted operations. Furthermore, the MPU can be swiftly commissioned and fully operational within 6 mos–12 mos.

The coating technology developed by TFP Hydrogen and integrated within the MPU effectively addresses the material challenges associated with titanium components in PEM electrolyzers. These components included porous transport layers, bipolar and unipolar plates, and cell separators. The range of innovative coatings provided by TFP Hydrogen plays a central role in enhancing the durability of the components, shielding against corrosion and minimizing contact resistance, ultimately improving the overall operational efficiency and extending the lifetime of the electrolyzer, thereby driving down long-term costs associated with green H2 production.

H-TEC SYSTEMS and EKPO cooperate to develop stack components for PEM electrolyzers

EKPO Fuel Cell Technologies GmbH (EKPO) and H-TEC SYSTEMS have agreed on a development contract to realize PEM electrolyzer stack components. As part of the cooperation, EKPO will contribute its know-how in developing large-scale production components and scrap reduction through a highly automated production level. The development and production of the prototypes that will be delivered to H-TEC SYSTEMS as part of the agreement will take place in Germany.

The stack components will be specially designed and developed for use in PEM electrolyzers in the megawatt (MW) range. H-TEC SYSTEMS is building its new stack manufacturing and development center, which will be one of the largest of its kind in the world, in Hamburg-Rahlstedt. At this new, ultra-modern and climate-neutral production and development plant, the H2 expert wants to produce PEM electrolysis stacks with a potential total electrolysis capacity of up to 5 gigawatts (GW) in a highly automated process to facilitate the global H2 ramp-up. The stacks form the heart of the PEM electrolyzers, which are built at the company's headquarters in Augsburg in Bavaria.

EKPO's expertise is based on more than 20 yr of experience developing and researching fuel cell technology. The joint venture benefits from the metal processing expertise of the parent company, ElringKlinger, and can also access the elastomer technology division's fundamental knowledge during this development project.

Nu:ionic Technologies and Liberty partner for 2.4-tpd H2 production equipment

Nu:ionic Technologies has entered into a Memorandum of Understanding (MoU) with Liberty Utilities (Gas New Brunswick) LP for the development of a 2.4-tpd (2,400-kg/d) H2 production system, utilizing Nu:ionic’s proprietary microwave catalytic reformers (MCRs). Liberty will utilize the facility to pilot H2 and natural gas blending. This is the first commercial application of Nu:ionic’s onsite, on-demand H2 production technology using microwave energy to decarbonize natural gas with electrified reforming.

Nu:ionic’s highly efficient microwave reformers eliminate the need for fuel combustion, greatly reducing the amount of feedstock required to produce H2 and significantly reducing greenhouse gas (GHG) emissions, while also allowing for the efficient use of renewable electricity to reduce the carbon footprint of the natural gas grid.

Nu:ionic’s proprietary process technology will generate low-carbon H2 at low cost, for blending into Liberty’s natural gas distribution system, clean power generation and fuel production for zero-emissions fuel cell electric vehicles in the heavy-duty and mass transportation sector. The MCR design includes a carbon capture system to produce readily transportable liquid CO2. Nu:ionic will also provide equipment commissioning, maintenance and remote monitoring support for the components.

The proposed facility is scheduled to be operational in the first half of 2025, and Liberty is negotiating with H2 and CO2 offtakers. When fully operational, this pilot-scale H2 blending project is projected to have the GHG capture capacity equivalent to more than 400 hectares (1,000 acres) of forest; depending on the use of the H2, this could potentially result in significantly more GHG emissions reductions.

Conventional steam methane reforming, the most prevalent reforming approach to H2 production and responsible for significant CO2 emissions, requires large amounts of natural gas (methane) as feedstock and a fuel source and cannot be cost-effectively deployed with carbon capture at distributed production capacities.

Nu:ionic Technologies’ MCR process uses approximately 30% less natural gas compared to conventional reformer methods, reducing the associated upstream emissions of natural gas exploration, production and transmission and eliminating the need for cost-prohibitive post-combustion carbon capture. It is also significantly more compact compared to conventional equipment. The MCR process results in more than three times the CO2 reduction per unit of renewable electricity used than electrolysis.

Owner-operators benefit from lower capital investment, a simplified, modular and compact equipment design, increased energy efficiency and the ability to cost-effectively produce H2 with 90% lower emissions.