Articles

The H2 economy will not accelerate without compressed air energy storage

Executive Viewpoint

M. HOWITT, Chief Technical Officer and Co-founder, Storelectric, Cheshire, UK

Today’s global energy systems are based on two major elements: methane (CH4) and electricity. However, this is set to change in the not-too-distant future. We expect future energy networks to be like today’s networks—the biggest change is that hydrogen (H2) will replace CH4 in the gas grid. H2 will power different things to natural gas, and in turn, the proportion of electricity will rise by at least two-fold.

Transitioning to an electric and H2 economy. In recent years across various markets, grid investments have increasingly been made to establish H2-compatible infrastructure. Why? Because the role H2 will play in the energy transition is significant, focusing primarily on the gas grid, industrial processes (e.g., iron and steel making), high-temperature heating, transportation, synthetic fuels and catalyzing other processes such as compressed air energy storage (CAES). In real terms, this means most H2 solutions must be at the same scale as the gas plants and equipment that they replace.

Of course, electricity is needed to make the H2, which will be used to make synthetic fuels—mainly H2 and electricity will be transmitted along networks. When it comes to H2’s relationship with today’s gas and electricity grids, they are mutually complementary and compete little with each other. Again, some applications presently use both.

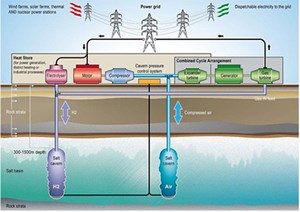

The CAES solution. CAES uses excess or cheap energy (i.e., from an electricity grid or renewable generation) to compress air to a high pressure: 70 bar–90 bar (30–40 times the pressure of a car tire) is typical. When the energy is needed again, the air is released to power a turbine that regenerates the electricity. Because compressed air is not very energy-dense, large volumes are required. Therefore, geological storage is used; existing CAES uses salt caverns that are manufactured within salt basins located around the world (FIG. 1).

When air is compressed to 70 bar, it heats up to ~650°C. However, air cannot be stored in salt caverns much above ambient temperature or the cavern will deteriorate. So, traditional CAES wastes the heat of compression in a cooling tower. Expanding the air then cools it to below –150°C, so the air requires re-heating (traditionally by burning gas). This is the case with existing plants at Kraftwerk Huntorf in Elsfleth, Germany and Plant McIntosh in Georgia (U.S.), which run at roughly 42% and 50% efficiency, respectively.

The author’s company’s H2 CAES solutiona operates similarly, but 10%–15% more efficiently. It is also H2 ready, but until sufficient H2 is available at suitable prices, it can burn natural gas or any mix of H2 and natural gas, making it ideal for the energy transition. H2 can be obtained either from the gas grid (which many countries will convert to H2 and, sooner, mixes of H2 and CH4) or dedicated production onsite or near-site; the plant will decarbonize as the gas grid decarbonizes. For developers, this is hugely important given the costs and complexities of transporting H2.

The author’s company’s adiabatic green CAESb, however, has successfully patented the technology to achieve 68%–70% round-trip efficiency by storing the heat of compression to re-use during expansion, thereby balancing the heat over the whole cycle of compression and expansion and eliminating emissions. The system features zero-to-low emissions and a levelized cost below that of gas-fired peaking plants. Hybrid arrangements are also available to get the best of both systems. The company’s technologies are built with off-the-shelf equipment and are therefore less expensive than traditional CAES.

Both CAES technologies will operate at scales of 20 MW–multi-GW and durations from 4 hr–multi-day. They are more cost-effective and configurable than other technologies to suit a vast range of applications/use cases while delivering grid stability based on real inertia. Real inertia is far superior to synthetic, which is an ultra-fast response time. The pre-transformation grid had no need of such speeds of response because it had enough real inertia. Moving away from that has harmed the grid’s cost-effectiveness, reliability and resilience. Nearly all long-duration energy storage (LDES) delivers real inertia, and the author’s company’s technology provides 24/7 operation at higher rates than an equivalent-sized power station.

The role of H2-powered generation in the natural gas supply chain. If seasonal storage is needed (and the jury is still out on that), then H2-powered generation will be essential as the most cost-effective way of storing such vast amounts of energy. In any case, the cycle of renewable generation to electrolysis to H2-powered generation to electricity on the grid is, at best, 45% efficient.

When it comes to gas, H2 is perfect for the grid. A mix of up to 10%–15% with natural gas can be achieved with minimal modifications and upgrades. Such activity is already underway in the Netherlands and Italy—with numerous plans and projects in motion elsewhere—as countries transform their natural gas infrastructure to enable the transportation of H2. However, beyond the 10%–15% mix, the use of H2 is inappropriate until 100% is reached: a mix is only useful when it is being burned, and the applications for which H2 is best suited require 100% purity.

Making the jump from 15% H2 to 100%. The jump to 100% H2 grids can most easily and inexpensively be made by creating H2-industry hubs in which H2 is both produced and used in bulk. These hubs can then expand to neighboring areas, eventually merging to include the entire grid. Additionally, most long-distance pipelines have multiple pipes side-by-side that can be converted one pipe at a time, as the Netherlands is doing with its “Hydrogen Backbone” project to create a national H2 ring.

H2 producers can then use the author’s company’s massive-scale bulk storage for buffering their output and providing reserve capacity, whether for gas grids or for users of pure H2 within the “island grid.” Once they have the capability, producers will focus their activities on transporting directly to their customers while other producers take their place in feeding the 10%–15% mixed-gas grid. In turn, this will greatly accelerate the transition to the widespread use of H2 across global energy systems and the industries that use it.

The key point to realize here is the huge opportunities for first-mover advantage in this space. The businesses that establish themselves first, at scale, will be the ones leading the global supply of H2 as the transition gathers pace.

Storage solutions for the H2 economy. H2 will require as much storage per unit of demand as the gas grid, although the author believes the H2 economy will require about half the demand as the electric economy grows and partially supplants demand. This can be tempered by the fact that H2 generation can be local, which could reduce the importance of strategic stocks held in case of geopolitical or economic turmoil.

However, this does not mean that a significant amount of bulk storage is not required—perhaps even more will be required, as the energy density of H2 is approximately two-thirds that of CH4. This is why, if governments are serious about the H2 economy, the integration of storage solutions to the grids must be prioritized.

Presently, the only way to store H2 in the needed vast quantities is in salt caverns, like those the author’s company will use (at least initially) for its CAES solutiona. Across the 9,000 available salt caverns in Europe (and the potential for many times more, seen in FIG. 2), of which many are adjacent to industrial sites like Teesside in the UK, the author’s company can provide integrated projects that are safer, more efficient and cost-effective.

Developing plants for long-duration storage. First-of-a-kind plants must be supported and encouraged by all technologies that offer a potential solution. The support for these technologies could be limited, so only the most cost-effective should be built. They also require contracts that suit them: all such technologies have long construction lead times—the biggest issue being the time that grids take to make the connections—and are naturally inertial, so they deliver a range of services to the grid that cannot be delivered separately and so should be contracted together.

The CAES opportunity. CAES is a proven solution. The author’s company’s versions offer between 60% and 70% efficiency (depending on size) while utilizing off-the-shelf technologies, are ready for widespread scale and can immediately be integrated within electricity systems.

Compared to other long-duration energy storage (LDES) solutions, such as pumped hydro or liquid air energy storage (LAES), CAES boasts the lowest capital expenditure (CAPEX) with an efficiency that is almost as high as that of pumped hydro (which is much more expensive and disruptive) and much higher than all other known LDES (including other CAES) technologies.

It is vital that investors and governments work with experts to integrate LDES into the electricity grid. There is real urgency for storage solutions to be prioritized when it comes to grid connectivity. The sooner investors and policy makers understand this, the sooner they will realize returns, including progress towards net-zero targets and profit generation.

The intermittency challenge. Most developed countries—including those in Europe and the U.S. (as well as China and India)—are decarbonizing fast. To power grids primarily through wind and solar power would require at least a tripling of the grid’s size to manage the intermittency of renewable generation; it would also require the procurement of expensive balancing and ancillary services. Connecting renewables to the grid through LDES can vastly reduce the extent and costs of both grid reinforcement and services procurement.

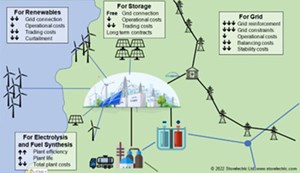

Many people suggest using electrolysis to remove the intermittency of renewable generation, but electrolysis—and most technologies that utilize H2—is hampered by intermittency, which reduces efficiency and plant life while multiplying the investment needed.

Solely using electrolyzers is clearly not a viable long-term solution to balancing intermittent generation, but why is that? First, flexing the electrolysis process only addresses that intermittency while ignoring the variability of electricity demand, so it only does half the job that CAES can do. Secondly, even ignoring the reduction in efficiency and plant life, such flexing requires some 2.5–8 times the amount of expensive electrolysis equipment than if supplied by baseload electricity, which the appropriate configurations of CAES can provide. Powering electrolysis with curtailed electricity would further require more than twice as many electrolyzers.

The above applies equally to plants that use H2 (e.g., fuel and chemical synthesis, iron and steel making) and plants that use electricity, such as nitrogen fixing, water treatment and desalination. The more integrated these developments are, the more efficient and cost-effective they will be. The author’s company’s CAES can be a key to enabling both the electricity system and the entire H2 economy (FIG. 3).

Takeaway. Intermittency is a solvable challenge. Using the proprietary CAES solutiona to eliminate intermittency before it hits the electrolyzers (and other plants) is extremely cost-effective, enhances efficiency and extends plant life. This highlights the value of ensuring H2 industrial sites are localized and integrated with storage, supply and demand. The more integrated the local H2-related industry is, the more efficient and cost-effective it will be.H2T

NOTES

a Storelectric’s Hydrogen CAES™

b Storelectric’s adiabatic Green CAES™

About the author

MARK HOWITT is the Chief Technical Officer and a Founding Director of Storelectric. He is also a United Nations expert advisor in energy transition technologies, economics, regulation and politics; a member of the UK advisory team to the International Energy Agency (IEA); a member of the Energy Storage Steering Group of the Renewable Energy Association; a frequent consultee to the British Energy Ministry, Regulator and National Grid; and an experienced speaker at many conferences.

A graduate in physics with electronics, he has 12 yr of global management and innovation consultancy experience before moving into senior management in industry. In a rail multinational, Howitt transformed processes and developed three profitable and successful businesses in commercializing a non-destructive technology he innovated, in logistics (innovating services) and in equipment overhaul. In electronics manufacturing, he has developed and introduced five product ranges and helped two businesses expand into new markets.