Articles

H2Tech: Tech Spotlight

H2 PRODUCTION

Fraunhofer IAP develops anion-conducting membranes for electrolysis

Highly conductive membranes for electrolyzers are a key component of H2 technology. A research team at Fraunhofer Institute for Applied Polymer Research IAP, together with Zentrum für Brennstoffzellen Technik ZBT GmbH, has developed innovative anion exchange membranes (AEM) that allow companies to reduce the costs of electrolyzers and tap the potential of H2 as a climate-neutral energy source in an environmentally friendly way.

Researchers at Fraunhofer IAP succeeded in synthesizing a new class of promising anion exchange polymers and manufacturing membranes from them, forming the basis for developing low-cost, efficient electrolyzers [anion exchange membrane water electrolyzers (AEM-WE)]. Developing the new anion exchange polymers and the resulting membranes is an important step for the H2 industry in Germany.

Available membranes, such as those from the Nafion brand, are based on the principle of proton conduction used in proton exchange membrane water electrolysis (PEM-WE). This requires catalysts made of expensive precious metals, such as iridium. Those membranes also contain a high proportion of PFASs, which degrade poorly in the environment and are suspected of possibly causing cancer. The newly developed AEM enables electrolysis operation with low-cost transition metals. They are free of PFAS and therefore applicable in line with the planned restriction process for PFAS within the EU chemicals regulation beyond 2025.

Based on the PPQs, the team at Fraunhofer IAP created hydroxide ion-conductive membranes suitable for applications in electrolyzers. The performance was evaluated by onsite tests conducted by Zentrum für Brennstoffzellen Technik ZBT GmbH. In electrolysis, the new membranes achieve a current density of 0.5 amperes per square centimeter at two volts. The specific conductivity for hydroxide ions of the newly developed membranes is about 8 millisiemens/cm at 60°C and 95% relative humidity.

ITM Power electrolyzer stack receives UKCA marking

ITM's state-of-the-art MEP30 electrolyzer stack has successfully been marked by United Kingdom Conformity Assessed (UKCA). Manufactured products deployed to the GB market after December 31, 2024, must have the UKCA marking.

This enables green H2 projects in the development stage to benefit from the required certainty of a UK-based partner offering products compliant with legislation that will take effect during their projects. The self-pressurized stack, which also maintains its CE marking for the EEA market, is the core element of ITM's proton exchange membrane (PEM) electrolyzer product portfolio.

ITM is also the first to announce UKCA accreditation, futureproofing and demonstrating continual development of their products, ensuring compliance with legislation crucial to serving the UK market. The legislation has been factored into the product design, with the marking applied in advance of the legal changes taking effect to ensure continuity and no disruption to the decarbonization efforts in the UK.

The UKCA mark is being phased in to replace the CE mark in Great Britain (England, Wales and Scotland). A product's mandatory marking indicates that it conforms to GB legislation, applicable for products placed on the GB market after December 31, 2024.

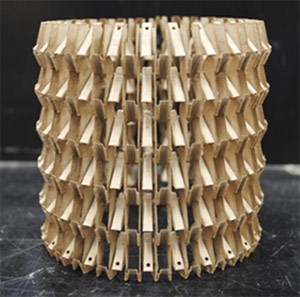

Honeywell and ZFRT commission structured catalyst for steam methane reforming

Honeywell and ZoneFlow Reactor Technologies (ZFRT) conducted pilot plant testing of the ZoneFlow™ Reactor in ZFRT’s large-scale pilot plant at Université Catholique de Louvain in Louvain-la-Neuve, Belgium. The near-commercial-level testing validated increased steam reforming capacity by at least 15% in feed flow compared to conventional state-of-the-art pellets, with no higher methane slip and without increasing the maximum tube skin temperature or pressure drop. This increased production of H2 allows for the steam methane reformer to convert hydrocarbon feeds such as natural gas or naphtha and steam into synthesis gas (syngas).

In 2021, Honeywell UOP and ZFRT signed a joint development agreement to grow and commercialize the ZoneFlow™ Reactor technology. This technology can significantly improve the productivity and cost-effectiveness of steam methane reforming for H2 and syngas production.

Tel Aviv University researchers produce highly efficient, low-cost green H2

Tel Aviv University researchers have achieved a groundbreaking milestone by producing highly efficient and low-cost green H2. By harnessing the power of green electricity and utilizing a highly efficient biocatalyst, this innovative process generates H2 without any air pollution.

H2 plays a vital role as raw material in both agriculture and industry. However, most of the H2 produced globally, approximately 95%, falls in the black or gray category. These types of H2 are derived from coal or natural gas, emitting a significant 9 t–12 t of CO2 for every ton of H2 produced.

The promising research results were published in Carbon Energy, focusing on advanced materials and technology for clean energy and CO2 emissions reduction. The researchers used a hydrogel (a water-based gel) to attach the enzyme to the electrode, and can produce green H2 utilizing a biocatalyst with over 90% efficiency.

H2 EQUIPMENT

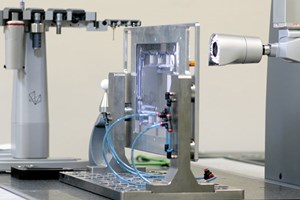

Cell Impact enables precise measurements in flow plate production for fuel cells

Fuel cell flow plates are created by forming very thin metal sheets with high velocity in a single stroke to create complex patterns. Extreme precision is required for the finished flow plate to work. With this new measuring technology, there is a unique capacity to measure up to one-twentieth of a single strand of hair.

The measuring facility is built as a separate entity within the company's factory in Karlskoga, Sweden to secure the best possible conditions. The slightest vibrations affect the measurement result—as do temperature changes. Therefore, there is no contact between the room and external walls and the temperature is kept at 20°C around the clock, with a permissible variation of 0.4°C. The measuring equipment measures flow plates, forming tools and fixtures.

Investing in new measurement technology is part of Phase II, Cell Impact's strategy to develop its offering and productivity, aiming to better satisfy the customers' development objectives. The instruments include Hexagon Global Blue 7.10.7, Hexagon Global Blue 12.22.10 and Leitz PMM Gold 7.7.5, and give Cell Impact better opportunities to measure complex geometries quickly, accurately and continuously.

GSR Ventiltechnik introduces new valve series for the H2 sector

GSR Ventiltechnik GmbH & Co. KG has developed a new valve series for the H2 sector. The direct pressure-controlled valves are characterized by a long service life, which is achieved by the unique design of the stem seal. It enables 35% more switching cycles than comparable competitive products.

The generation of electricity from wind and solar power plants will be massively expanded in the coming years. However, since these forms of electricity generation are subject to fluctuations due to the time of day and weather conditions, and the electricity generated cannot be stored easily, new concepts are still needed here. The production of green H2 from the surplus electricity of renewable energy plants could be the solution. H2 can be temporarily stored, transported and used in gas grids, or converted back into electricity in gas turbines.

This green H2 is produced by splitting water (H2O) into H2 and oxygen (O2) using electrolyzers and renewable electricity. The new externally controlled valves from GSR control the processes surrounding electrolysis.

A version for H2 and O2 processes will be available soon. The body materials have been specially qualified for use with H2 or O2. The H2 version has reliable, tested sealing elements; these are even BAM-certified for the O2 version.

The valves are optimally designed for the prevailing pressure and temperature ranges, have excellent flow characteristics, and feature sophisticated materials that ensure long service life.

Oxford nanoSystems develops coating technology to accelerate the adoption of green H2

Oxford nanoSystems (OnS), an advanced materials technology company, has announced a breakthrough in the race to reduce the production cost of zero-emissions green H2. OnS’ proprietary coating, nanoFLUX, improves the H2 production capacity of alkaline electrolyzers by over 50%. This is a significantly lower cost than current state-of-the-art coatings. The coating will accelerate the transition to a H2 economy by radically reducing production costs. It also addresses the key challenge of making green H2 competitive against fossil fuels.

nanoFLUX, an advanced metallic-alloy coating applied to the electrodes, promotes the formation and release of gas bubbles within the electrolyzer. This enhances the overall efficiency of the process. This innovative coating has been combined with a proprietary catalyst that accelerates the H2 generation reaction.

An independent assessment conducted by E4Tech (part of the ERM Group), a leading international consulting firm focused on sustainable energy technologies, confirmed the breakthrough cost-benefit advantage of nanoFLUX.

MAN compressor technology set for Louisiana clean energy complex

Air Products & Chemicals has awarded MAN Energy Solutions an order for six air-compressor trains for use in an air-separation unit in its Clean Energy Complex in Darrow, Louisiana (U.S.). The complex will produce more than 750 MMsft3 of blue H2 daily (which will be transported along a 700+ miles pipeline on the U.S. Gulf Coast) for Air Products’ customers, and blue ammonia for global H2 markets such as the transportation and mobility sectors. The facility will also capture and permanently store about 95% of its CO2 emissions—over 5 MMtpy—equivalent to the annual CO2 emissions from more than 1 MM passenger cars.

MAN's air-compressor trains will be deployed at the core of Air Products' air-separation unit, separating the air into its primary constituents of oxygen and nitrogen. Both gases are needed to produce H2 and ammonia.

Air Products' Clean Energy Complex is expected to commence commercial operation in 2026. For MAN Energy Solutions, the installation will add to an already extensive list of air-compressor train references with more than 250 air-separation facilities with MAN compressor technology currently in commercial operation globally.

MAN Energy Solutions' scope of work for Air Products' blue H2 energy complex comprises two air-compressor trains—each equipped with a single shaft compressor type, RIKT 160-3. It includes two booster air-compressor trains—each with an integrally geared compressor type, RG 63-6—and two gaseous nitrogen compressor trains—each with an integrally geared compressor type, RG 45-5. All the trains will be electrically driven.

The main air-compressor trains—the largest in MAN’s RIKT portfolio—have three centrifugal stages and deliver more than 600,000 Nm3/hr of air. The booster compressors are integrally geared and have six (air) and five (nitrogen) stages, all with external intercoolers.

H2 APPLICATIONS INNOVATION

MAHLE wins series order for H2 engines

MAHLE has received a series order from engine manufacturer DEUTZ to develop and supply components for H2 engines. These are so-called power cell units—units consisting of a piston, piston ring pack and piston pin—which DEUTZ plans to use in stationary H2 engines for the first time at the end of 2024. Further applications in the off-highway sector, such as agricultural and construction machinery, are planned.

These new engines can be operated climate-neutrally using H2 produced from renewable sources since no CO2 is produced when the H2 is burned. MAHLE has been working on engine systems for H2 and other climate-neutral fuels for years. The Stuttgart-based technology group is contributing this expertise to the DEUTZ project.

For use in the H2 engine, MAHLE has adapted and further developed the aluminum piston and piston ring pack from classical diesel technology. In H2 combustion, a key challenge is finding the optimum between the gas mixture forced into the crankcase during the combustion process and the oil consumption. MAHLE has already verified the reliability of the H2 components in a wide variety of engine classes.

H2 STORAGE AND TRANSPORTATION APPLICATIONS

GTT receives AiP for new tank concept for transporting liquid H2

GTT has received an Approval in Principle (AiP) from ClassNK for a new concept of membrane type containment system for liquefied hydrogen (LH2). As part of the energy transition toward a carbon-free future, the ability to transport H2 in the liquefied form at -253°C is one of the technological challenges to building a reliable, efficient and competitive H2 supply chain.

To this end, GTT has developed a scalable containment system, which can be adapted to any size of LH2 carrier without major design modifications, as well as the cargo handling system, the design of which has been validated based on ClassNK rules accompanied by a risk analysis.H2T