Articles

Coriolis and thermal mass flowmeters are essential to maximize tax credits

H2 Equipment and Services

M. FLANNERY, C. MARCON, Endress+Hauser, Greenwood, Indiana

The $369 B of renewable energy initiatives in the U.S. Inflation Reduction Act (IRA) are promoting the shift to green energy with several incentives. Along with public appeal, the availability and flexibility of the various tax credits are projected to spur interest in energy transition projects.

Solar and wind have received most of the attention over the past decade, but their intermittent nature can be a drawback for long-term viability because synchronizing power supply with demand around the clock is difficult. Batteries help with the balancing act, but only for short-duration storage. This is where hydrogen (H2) shines because it can be produced using excess electricity by way of electrolysis—which splits simple liquid water (H2O) into its component H2 and oxygen (O2) gases—and then stored for long-duration use when power is required.

Of the various incentives outlined in the IRA, the H2 production tax credit remains one of the least defined and most actively debated. The stipulations surrounding this tax credit, and the conditions where it applies—including hourly matching requirements for renewable energy—are ambiguous. The complexity lies in the bill’s tiered tax incentives based on the carbon intensity of the H2 produced. The highest tax credits are issued for the least carbon intensive H2 processes, reaching up to $3/kilogram (kg).

This production tax credit is meant to accelerate the learning curve and reduce the costs of producing low-carbon H2 over time. However, rules for measuring carbon intensity and potential allowances of mechanisms to offset emissions, such as renewable energy credits, are still under development (i.e., hourly vs. annual matching). These rules may have significant implications for the economic competitiveness of electrolytic H2 production.

As a result, H2 carbon intensity calculations have created discussions in industry and political circles. According to a study by Wood Mackenzie, the debate largely centers around electrolyzers that rely on grid electricity for all or part of their energy needs. Some organizations would like to see green H2 developers prove they are consuming 100% renewable power by matching their electrolyzer’s electricity consumption to renewable-power generation on an hourly basis. Others are arguing that these requirements will limit the economics and deployment of green H2 projects.1

While the regulations and reporting rules remain foggy in this emerging industry, producers can implement measures to prepare for successful H2 metering that are independent of carbon intensity and, therefore, outside of the current policy debates.

Volumetric flow measurement insufficient. Maximizing the H2 production tax credit—which is paid per kg—depends on an accurate mass flow measurement. The credit is calculated according to the carbon intensity and mass of gas produced, although most producers measure quantity by volume, then multiply by density to convert the figure to mass. Because H2 density is much lower than other gases (TABLE 1), measuring flow accurately can be challenging, especially in changing process conditions. This creates uncertainties, which can cause measurement errors.

For these and other reasons, there is speculation that producers will be required to measure H2 production using direct mass flow measurement methods. However, even if conversions are allowed, these calculations have the potential for underreporting, decreasing the tax credits available.

Regardless of where the measurement and reporting requirements land, direct mass flow measurement can ward off audits or other scrutiny that may otherwise be present with volumetric flow measurement converted to mass.

Two common technologies for measuring mass flow are Coriolis and thermal dispersion. Leading suppliers provide both options, along with support for proper selection and sizing.

Mass flow measurement maximizes tax credits. The low density of H2 gas compounds the inaccuracies of converting volumetric flow to mass, as even seemingly small errors can result in large flow reading corrections. As industry scales, high pressure and large line sizes may become increasingly common, further intensifying errors. It is typically easier to measure fluid flow at high pressure, but measuring H2 before it is compressed yields a more accurate result.

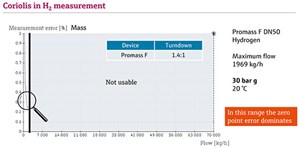

Rangeability, or turndown, with mass flowmeters is typically very large, enabling the use of a single meter in many applications—even those with wildly varying flowrates. However, this measuring range is reduced significantly when measuring low-density fluids, as is the case with H2, making it necessary to ensure appropriately sized instrumentation.

Coriolis flowmeters. Coriolis flowmeters are useful for measuring the mass flow of numerous fluids, such as solvents, fuels, crude oils, vegetable oils, gases and liquefied gases. In gas streams, they are capable of multivariable measurement, including mass flow, corrected volumetric flow, density, temperature, solids content, concentrations in multi-phase fluids and others.

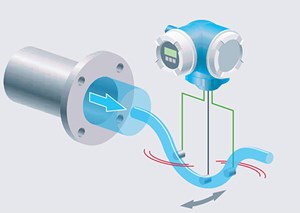

Coriolis meters consist of one or more measuring tubes that oscillate via an artificially induced pulse from an exciter. As fluid flows through each tube, its inertia imposes additional twisting, changing the oscillatory pattern. Two detectors—one upstream of the exciter and the other downstream—distinguish this phase difference, which directly correlates to the mass flow (FIG. 1).

Additionally, oscillation frequency can be used to determine fluid density and viscosity, and the sensors measure temperature to compensate for thermal influences. These signals are often available from Coriolis instruments as secondary process variable outputs.

Coriolis flowmeters are characterized by their high accuracy, typically within ±0.1% or less, and they remain accurate regardless of physical fluid properties and flow profile. Additionally, these sensors do not require an inlet or outlet straight pipe run, increasing installation versatility over other flow measurement methods.

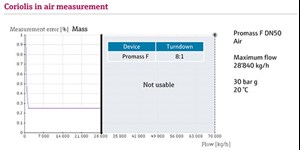

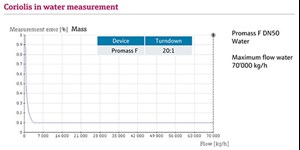

Typically, Coriolis flowmeters exhibit respectable turndown (FIGS. 2 and 3), but because of H2’s extremely low density, this ratio is significantly reduced (FIG. 4).

Additional design considerations include relatively high cost, large size, lack of availability for pipelines more than 16 in. diameter, and some reduction in line pressure.

Thermal mass flowmeters. When high turndown and/or low-pressure loss are critical, thermal mass flowmeters are often the most desirable choice for flow measurement in process control and monitoring applications. These instruments are particularly useful for measuring gas flow, even in large pipelines and irregularly shaped ducts.

Thermal flowmeters work on the principle of heat transfer, transmitting energy from a heated probe to the fluid as it flows past. The sensor is comprised of two PT100 temperature probes. One is used to measure the current fluid temperature as a reference, while the second is heated to maintain a constant temperature differential relative to the first.

As fluid flows past both probes, energy is transferred from the heated probe to the fluid, cooling this probe. The sensor, meanwhile, supplies the required electricity to maintain the temperature differential between the probes, which is proportional to mass flow, with higher flow corresponding to greater heat transfer (FIG. 5).

Thermal mass flowmeters provide excellent low-flow sensitivity and a high turndown ratio, often 100:1 or more. Additionally, these instruments do not require pressure or temperature compensation like other flowmeters and react quickly to flow fluctuations for consistent accuracy. Temperature is available from most thermal mass flow transmitters as a secondary process variable.

Because H2 is so light, its presence can be difficult for Coriolis flowmeters to capture at low pressures, making thermal dispersion flowmeters the preferred choice. However, at higher flowrates, H2 can draw heat away from thermal probes too fast for the meter to sustain.

Additional design considerations for thermal mass flowmeters include the need for a fully developed flow profile, a rigid definition of a static gas composition, the limited ability to measure wet gas/steam and accuracy reduction from sensor buildup.

Diagnostic data provides accuracy assurance. Leading modern digital instrumentation comes equipped with smart diagnostics, providing increased accuracy and quality assurance over time. These data and capabilities can include sensor health parameters, process disturbance recognition (e.g., deposits, abrasion, corrosion, multiphase fluids), calibration records, onsite verification techniques and more.

Collectively, these attributes provide verification alternatives that can often extend calibration intervals, along with sensor degradation warnings to enable predictive maintenance and reduce downtime due to failure. As H2 producers expand operations to multiple trains, digital data by default significantly simplifies process management at scale, empowering the use of cloud-based software for data collection, visualization and analysis.

H2 blending success for natural gas-fired turbines. H2’s role in the energy transition was recently put on display at an Appalachian U.S. 485-MW power plant by blending H2 with natural gas feedstock to reduce emissions. H2 burns cleaner than natural gas, providing a path for partial decarbonization.

The H2 co-firing effort required:

- An accurate H2 injection system with blend validation

- The ability to scale operations easily and efficiently

- Modern, smart measurement technology

- Safety assurance.

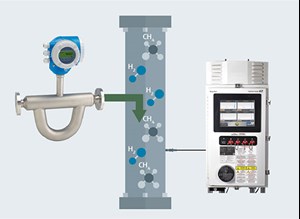

To meet these and other objectives, the power plant partnered with a leading instrument supplier to design and implement a system to safely control the sensitive H2 and natural gas blend. The facility was fitted with two Coriolis flowmetersa,b—one at the H2 injection point and the other downstream to measure main line gas flow—in addition to a Raman analyzerc to measure and validate H2 doping (FIG. 6). This setup provided precision accuracy, well within the required error band of 0.25%, without requiring restrictive upstream or downstream straight-run piping.

Raman spectroscopy-based analyzers perform precise measurements by employing laser light and optical analysis techniques to determine the constituents in a gas and its concentrations. The instrument’s probe requires only 15 sec to conduct an accurate snapshot of the gas under measurement, enabling near instantaneous feedback to the control system regarding the integrity of the gas blend, helping prevent H2 overshoot (FIG. 7).

Four comprehensive and successful tests of injecting and controlling 5% blends of H2 in natural gas have been completed to date. Both flowmeters in the application comply with the U.S. Environmental Protection Agency (EPA) standards on fuel flows for calculating emissions, including adjusted emissions after introducing H2. Additionally, the analyzerc provides calculations of the Wobbe Index, a number for comparing the energy output of different gas blends. This is critical when using alternative fuel sources like H2, which has a lower British thermal unit (Btu) per volume than natural gas.

The main modifications required to enable the use of H2 blends were external to the turbine, an encouraging detail for future use of alternative energy sources. There are tens of thousands of gas turbines in operation worldwide and, with similar small adjustments and retrofitting, many of these can also run on H2 blends, which will help decarbonize electricity generation.

Prepare operations for profitable H2 production. As the energy transition moves forward, reliable means of storing energy are in greater demand, and H2 is proving to be a worthy vessel. With the IRA’s H2 production tax credit, producers are incentivized like never before to produce and report low-carbon intensity H2.

As the debate between hourly matching and unrestricted electrolytic H2 production continues, producers can position themselves for success regardless of where the legislation lands by fitting their applications with reliable and accurate mass flowmeters. With low-carbon intensity H2 becoming more prevalent and power generation facilities committing to decarbonization goals, both industry and society are bound for a more sustainable future.H2T

Notes

a Proline Promass Q meter

b Proline Promass F meter

c Raman Rxn5 analyzer

LITERATURE CITED

1 Wood Mackenzie, “Green hydrogen: What the Inflation Reduction Act means for production economics and carbon intensity,” March 2023, online: https://www.woodmac.com/news/opinion/green-hydrogen-IRA-production-economics/#:~:text=The%20Inflation%20Reduction%20Act's%2045V,up%20to%20US%243%2Fkg

About the authors

MASON FLANNERY is a Product Marketing Manager for Flow Measurement products at Endress+Hauser. He started his career with Endress+Hauser in the Rotational Engineering Program and has spent time in tech support, inside sales, application engineering and as a Regional Flow Product Business Manager. Flannery has extensive field experience with flow measurement in industrial environments and a wide range of application knowledge. He earned a BS degree in industrial distribution from Texas A&M University.

CORY MARCON is the Power and Energy Industry Marketing Manager for Endress+Hauser U.S. and is responsible for the overall business development and growth of the company position related to traditional power generation and the energy transition. As part of his role, he serves as the U.S. representative in the global Strategic Industry Group (SIG), helping develop education, the long-term vision, brand and product direction within Endress+Hauser as the world actively works toward carbon neutrality. Marcon is a 2012 graduate of McGill University with a decade of experience in many forms of energy, including solar, wind and gas.