Articles

H2Tech: Tech Spotlight

T. CAMPBELL, Managing Editor

H2 EQUIPMENT

Honeywell launches 100% hydrogen (H2)-capable gas meter

Honeywell has announced the European launch of its 100% H2-capable diaphragm gas meter. The Honeywell EI5 smart gas meter, successfully piloted in the Netherlands, is part of a broader initiative to align with the region’s goals outlined in the European Green Deal.

The new gas meter can measure H2 and natural gas, providing adaptability across the European continent. Once installed, these meters eliminate the need for future replacements, even as networks transition to H2, thereby reducing long-term costs and enhancing operational sustainability. The EI5’s design and functionality have been tested and certified by Physikalisch-Technische Bundesanstalt, ensuring its safety, accuracy and preparedness for the evolving energy landscape.

In the Netherlands, the gas meters will be delivered to Enexis Group, one of the country’s largest gas distributors, following a pilot project in Wagenborgen. This pilot project is transforming residential homes from the 1970s, integrating them into a H2 network that includes the EI5 gas meters and a H2 central boiler for heating and hot water. The project aims to pioneer green H2 through electrolysis, marking a significant step in sustainable energy usage.

Viritech launches H2 refueling solution

Viritech, a developer of H2 powertrain solutions, has launched its new refueling product, H2 Fill. H2 Fill has been designed to offer a flexible, efficient and cost-effective solution for various H2 powertrain applications.

One of the key benefits of H2 vehicles over battery-powered vehicles is their faster refueling times. However, H2 pressure vessels operate at very high pressures, and vehicles often have multiple pressure vessels, requiring accurate control of the refueling process. In compliance with the Society of Automotive Engineers (SAE) J2799 standards, H2 Fill automatically communicates with the refueling station and can monitor multiple vessels for temperatures and pressure during the refueling cycle.

Regarding its technical specification, H2 Fill communicates via infrared (IR), using the IrDA protocol (as per the SAE J2799 standard), and can also be supplied without an IR sensor for applications where a sensor is already pre-installed. Viritech can also assist customers with vehicle integration of H2 Fill.

Oxford Flow expands its product range, grows market potential with new high- and low-pressure pilots

Oxford Flow is launching two new pilots—designed for high- and low-pressure environments—following customer feedback while adapting to market demand in gas distribution networks (GDNs).

In a GDN, gas regulators play a crucial role in managing and maintaining appropriate pressure levels throughout the system, with the pilot serving as the control mechanism that helps ensure consistent output. Designed for use with Oxford Flow’s H2-ready IM series gas regulators, the new high- and low-pressure pilots will expand Oxford Flow’s market potential and offer the GDN operator a solution that can be used throughout its system, with differing pilots in each pressure area.

The PRX2H high-pressure pilot is ready to be deployed to customers, with the PRX2L low-pressure pilot due to be released to the market in early 2024. The new range of pilots includes: PRX2L low-pressure reducing pilot [13 millibar (mbar)–1.2 bar], PRX2 pressure reducing pilot (0.5 bar–25 bar), PRX2H high pressure reducing pilot (17 bar–70 bar) and PSX1 pressure sustaining/creep relief pilot (0.5 bar–22 bar).

H2 PRODUCTION

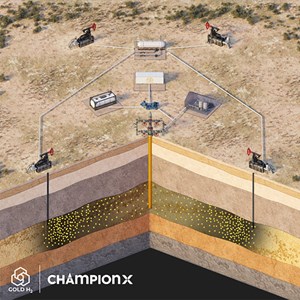

ChampionX and Gold H2 collaborate to advance subsurface H2 production

ChampionX Corporation and Gold H2 (GH2) have announced a strategic collaboration on field trials of GH2's novel H2 production technology. GH2, a subsidiary of Houston-based Cemvita Factory Inc., is working to advance the energy transition through its tailored subsurface microbiology solutions that use the power of microorganisms to enable onsite H2 production from depleted or uneconomical oil reservoirs, “known as Gold HydrogenTM.”

ChampionX complements GH2 with a portfolio of services and chemical technologies that optimize and enhance production from oil and gas reservoirs. As a market leader with expertise spanning the oil and gas lifecycle and a footprint in every major producing area, ChampionX is equipped to support GH2 through these exciting field trials.

HKU Engineering team develops new ultra stainless steel for H2 production

A research project at the Department of Mechanical Engineering of the University of Hong Kong (HKU) has made a brand-new breakthrough over conventional stainless steel by developing stainless steel for hydrogen (SS-H2).

The new steel developed by the team exhibits high corrosion resistance, enabling its potential application for green H2 production from seawater, where a novel sustainable solution is still in the pipeline.

The performance of the new steel in a saltwater electrolyzer is comparable to the industrial practice of using titanium as structural parts to produce H2 from desalted seawater or acid, while the cost of the new steel is much cheaper.

Since its discovery a century ago, stainless steel has always been an important material widely used in corrosive environments. Chromium (Cr) is an essential element in establishing the corrosion resistance of stainless steel. Passive film is generated through the oxidation of Cr and protects stainless steel in natural environments.

Unfortunately, this conventional single-passivation mechanism based on Cr has halted further advancement of stainless steel. Owing to the further oxidation of stable Cr2O3 into soluble hexavalent chromium Cr(VI) species, transpassive corrosion inevitably occurs in conventional stainless steel at ~1,000 millivolts (mV) [saturated calomel electrode (SCE)], which is below the potential required for water oxidation at ~1,600 mV.

The 254SMO super stainless steel is a benchmark among Cr-based anti-corrosion alloys and has superior pitting resistance in seawater; however, transpassive corrosion limits its potential application.

Using a sequential dual-passivation strategy, the research team developed the novel SS-H2 with superior corrosion resistance. In addition to the single Cr2O3-based passive layer, a secondary manganese (Mn)-based layer forms on the preceding Cr-based layer at ~720 mV. The sequential dual-passivation mechanism prevents the SS-H2 from corrosion in chloride media to an ultra-high potential of 1,700 mV. The SS-H2 demonstrates a fundamental breakthrough over conventional stainless steel.

For water electrolysis in desalted seawater or acid solutions, expensive gold- or platinum-coated titanium is required for structural components. For example, a 10-megawatt (MW) proton exchange membrane (PEM) electrolysis tank system costs approximately $2.28 MM, with the structural components contributing up to 53% of the overall expense. The breakthrough made by the research team makes it possible to replace these expensive structural components with steel, which is more economically friendly. As estimated, employing SS-H2 is expected to cut the cost of structural material by about 40 times, demonstrating great potential for industrial applications.

HGenium unveils first-of-its-kind technology for green H2 production

HGenium presented insights on the company’s breakthrough thermochemical water-splitting process at the 2023 American Institute of Chemical Engineers (AIChE) conference in Orlando, Florida. HGenium’s unique technology enables green H2 to be produced using readily available materials and processing equipment with various heat energy sources.

Key benefits of a thermochemical approach include:

- A wide array of heat sources can be used, such as concentrated solar, nuclear and industrial production process heat, widening the potential commercial cases for using a thermochemical process vs. electrolysis.

- The almost 70% lower cost of heat over thermal-based electricity opens the possibility of improved overall economics for many use cases.

- Storing heat has inherent safety and cost benefits over electricity storage.

A pilot plant project is underway, with operations targeted for 2H 2024, followed by the construction of a commercial-scale demonstration unit in 2025–2026. These steps will position the company and its partners to launch commercial units at substantial capacities in the future.

H2 APPLICATIONS INNOVATION

Caterpillar expands the range of H2-fueled power solutions

Caterpillar has announced the latest additions to its commercially available power solutions running on H2 fuel. Caterpillar’s lineup of gas generator sets capable of operating on natural gas blended with up to 25 vol% H2 now includes power nodes ranging from 60 kW–2.5 MW for 50 Hz or 60 Hz continuous, prime and load management applications. These include Cat CG132B and Cat CG170B generator sets and the G3500H series platform.

Additionally, the company offers aftermarket retrofit kits for updating select G3500H series platform products to provide the same H2 blending capabilities of up to 25 vol% H2.

These new generator sets add to Caterpillar’s portfolio of H2-capable power solutions. Since last year, Caterpillar has offered demonstrator Cat G3516 gas generator sets capable of operating on 100% H2. These sets are available with a maximum rating of 1,250 kW for 50 Hz or 60 Hz continuous applications.

H2 STORAGE AND TRANSPORTATION APPLICATIONS

Chart receives certification for liquid H2 bulk transport trailers

Chart has received Korean Gas Safety (KGS) certification and approval for its liquid H2 bulk transport trailers built in Theodore, Alabama, for the Korean market, making the company one of the first suppliers with a liquid H2 trailer design approved to serve the growing Korean market. Chart worked closely with KGS to ensure its stringent safety requirements were met. This trailer, specifically tailored to meet Korean regulations, offers > 3,100 kg of payload and is the latest addition to Chart’s portfolio of gaseous and liquid H2 trailers.

Viasea Shipping plans to build H2-powered container ships

Enova is providing $15.5 MM to Viasea Shipping to acquire two H2-powered container ships. Once completed, these ships will be deployed in Viasea's existing routes between Norway and Northern Europe. Viasea aims to take the lead and inspire the maritime industry to invest in emissions-free vessels. This vessel concept is designed for exceptionally lower energy consumption, combining new, emissions-free technologies such as green H2 and rotor sails to directly utilize nature's renewable energy.

The H2 refueling is initially planned in Norway. As H2 becomes available elsewhere along the planned route, the ships can operate entirely without diesel. The combination of H2 and diesel operation will result in a more than 75% reduction in CO2 emissions compared to an equivalent diesel-powered vessel. With 100% H2 operation, the ship will be emissions free.

Plagazi and Litra Gas partner for the transport and handling of circular H2

A Letter of Intent (LoI) details a commercial agreement between Plagazi and Litra that would enable Litra to transport circular H2 from Plagazi to various industrial sites and offtakers.

The background of the agreement comes from the mutual sentiment towards reducing emissions and promoting the production of significant volumes of sustainable forms of energy, such as circular H2. Litra operates a transport infrastructure for deliveries of compressed circular H2 gas and is interested in further contributing to the reduction of greenhouse gases entering the atmosphere. Plagazi is interested in collaborating with Litra to load and optimize transport equipment and deliver circular H2 to various sites indicated by Plagazi.H2T