Articles

The advantages of high-pressure H2 transport

Special Focus: H2 Equipment and Services

J. MITCHELL, BayoTech Hydrogen, Tulsa, Oklahoma

As the push for clean energy intensifies, H2 has emerged as a powerful contender capable of decarbonizing diverse sectors. H2, the lightest and most abundant element, presents a transformative alternative. Its versatility offers a clean energy solution for power generation, transportation and industrial processes. However, efficiently transporting this versatile fuel is crucial, and unlocking its potential hinges on efficient and cost-effective transportation.

This article details the advantages of high-pressure gaseous H2 transport, comparing it to traditional lower-pressure and liquid H2 transport methods. By examining efficiency, cost and technological advancements, this work will outline the potential of high-pressure trailers (FIG. 1) to revolutionize H2 distribution and unlock a sustainable future.

Efficiency advantages of high-pressure trailers. High-pressure compression technology offers substantial efficiency gains in H2 transport. Maximizing payload capacity per trailer reduces the number of transport trips needed, consequently cutting down on emissions. Moreover, high-pressure trailers' fast fueling and dispensing capabilities enhance operational efficiency (FIG. 2), making them a preferred choice in the evolving landscape of H2 logistics.

When it comes to transporting H2 efficiently, high pressure reigns supreme. High-pressure trailers unlock a treasure trove of efficiency gains by compressing H2 to higher densities. Imagine squeezing the equivalent of several low-pressure trailers full of H2 into a single unit. This dramatic increase in density translates to several benefits:

- Reduced transport trips: Imagine an industrial hub where H2 fuels diverse operations such as forklifts, backup power systems and fuel cell trucks. With traditional low-pressure trailers, a constant parade of delivery trucks would be required to keep up with H2 demands. However, high-pressure trailers pack significantly more H2 per trip, slashing the number of deliveries needed and dramatically reducing emissions associated with frequent journeys.

- Lower operational costs: Fewer trips equate to lower operational costs. Driving hours, fuel consumption for the transport vehicles, and wear-and-tear on equipment all plummet when high-pressure trailers are utilized. This cost reduction affects the entire value chain, making H2 more accessible and competitive across various sectors.

This efficiency extends beyond travel time and cost savings. High-pressure technology enables high-speed fueling and dispensing, optimizing operations. The efficiency gains of high-pressure trailers represent a paradigm shift in H2 transportation, enabling:

- Scalability: As H2 demand grows, the ability to store and transport larger volumes efficiently becomes crucial. High-pressure ground storage and transport trailers provide a scalable solution, adapting to increasing needs without requiring significant infrastructure overhaul. These options also provide a smaller footprint for those with space constraints.

- Decarbonization in action: By reducing trips, emissions and operational costs, high-pressure technology directly contributes to decarbonization efforts, paving the way for a cleaner future powered by H2.

By maximizing payload, minimizing footprint and accelerating fueling, high-pressure trailers emerge as a powerful tool for unlocking the full potential of H2 as a clean and sustainable energy solution.

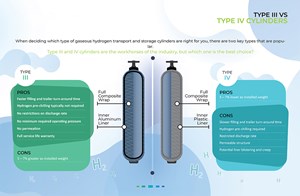

High-pressure cylinder technologies. The heart of a high-pressure trailer lies in its cylinders. These cylinders safely store H2, each type offering unique advantages. Two main cylinder types are the preferred choices for high-pressure H2 storage: Type 3 and Type 4. Both offer impressive capabilities, but Type 3 is more ideal for many applications. An overview of Type 3 vs. Type 4 cylinders is detailed in FIG. 3.

Type 3 cylinders boast a lightweight composite construction, offering a winning combination of high capacity and optimal pressure range. Their robust design ensures safety while minimizing weight, making them ideal for maximizing payload and minimizing transport emissions. Their impermeable metal liner also prevents H2 leakage, safeguarding the environment and operator safety. In addition, Type 3 cylinders are equipped to better handle temperature fluctuations during fast dispensing and filling of H2, increasing efficiency and lowering labor costs.

While Type 4 cylinders push the pressure boundaries, offering even higher capacities, their design comes with tradeoffs. They often utilize a polymer liner, which, although lighter than metal, may require pre-chilling during filling to manage temperature rise and potential material embrittlement. The process of pre-chilling also adds additional complexity and cost to the process. This increased sensitivity, added costs and possible safety concerns slightly tilt the scale towards Type 3 in many situations.

Ultimately, the optimal choice depends on specific needs. However, for diverse applications from distributed refueling stations to short-haul trucking, Type 3 cylinders, with their superior safety, operational flexibility and simpler handling, make them a preferred choice for efficient and reliable high-pressure H2 transport.

With ongoing research and development focusing on emerging cylinder technologies, innovations in materials science, such as advanced composites and metal alloys, show promise in further enhancing high-pressure cylinders' efficiency, safety and cost-effectiveness. As these technologies mature, they may play a pivotal role in shaping the future of H2 transport.

Exploring the advantages and limitations of each cylinder type is essential for tailoring H2 transport solutions to specific applications. The continuous evolution of cylinder technologies ensures that the H2 industry remains at the forefront of innovation, emphasizing the optimization of safety, efficiency and environmental impact.

High-pressure trailers vs. liquid transport. Creating a comprehensive comparison between high-pressure trailers and liquid H2 transport is crucial for understanding the advantages and disadvantages of each. Regarding H2 transport, the rivalry between gas and liquid boils down to a nuanced dance of strengths and weaknesses. While liquid H2 boasts a higher density than gaseous H2, its energy-intensive liquefaction, cryogenic storage infrastructure and loss of H2 from boil-off during regasification come at a hefty cost.

Conversely, high-pressure gaseous transport shines in operational efficiency. Distributed refueling stations and smaller-scale deployments are ideally suited to high-pressure trailers' flexibility and lower infrastructure requirements. For long-haul transportation, where energy density reigns supreme, liquid H2 may hold an edge. However, high-pressure trailers are rapidly narrowing the gap with technological advancements in cylinder materials and pressure ratings. Ultimately, the optimal choice depends on distribution distance, volume, end-use application and available storage space.

Cost benefits of high-pressure trailers. Beyond efficiency, high-pressure trailers excel in affordability. Compared to capital-intensive liquefaction plants and cryogenic storage tanks, high-pressure systems demand significantly lower upfront costs. Operational expenses also plummet with fewer trips, faster deliveries and reduced maintenance requirements. As adoption scales, economies of scale kick in, further driving down costs and making high-pressure H2 transport even more attractive.

Investing in an entire liquefaction system and cryogenic storage infrastructure to transport H2 involves high upfront costs, as well as additional costs for equipment needed for regasification. This typically hinders smaller players from investing in this technology, which can stifle widespread adoption. Conversely, high-pressure trailers present an affordable alternative. The more straightforward design and readily available manufacturing processes translate to substantially lower capital expenditures. Forgoing expensive liquefaction facilities for readily deployable high-pressure transport and storage options saves money and unlocks quicker market entry and faster project implementation.

Compared to the operational demands of traditional methods, high-pressure trailers deliver significant cost savings:

- Reduced trips: Fewer refueling trips due to higher payload capacity directly translates to lower operational costs. Less fuel consumption for transport vehicles, reduced driver hours, and diminished wear-and-tear on equipment contribute to a leaner operational budget.

- Faster delivery: Rapid fueling and dispensing capabilities minimize vehicle downtime, optimizing productivity and maximizing revenue potential. This speed-to-fuel advantage becomes even more crucial in time-sensitive applications like heavy-duty trucking or mass transit (FIG. 4).

- Lower maintenance: The robust design and readily available materials in high-pressure trailers offer lower maintenance requirements than the complex machinery associated with liquefaction and cryogenic storage. This translates to less downtime and reduced maintenance costs throughout the system's lifecycle.

The economic edge offered by high-pressure H2 transport trailers is more than just a financial advantage. It catalyzes sustainable growth, paving the way for a cleaner, more affordable energy future powered by H2.

Additional considerations and outlook. While efficiency and costs are paramount, the journey towards a H2-powered future demands a holistic approach. Robust standardization and regulations will ensure high-pressure trailers' safe and reliable operation, fostering public trust and industry-wide adoption. Addressing public perception through education and communication can dispel lingering concerns about compressed H2. Importantly, high-pressure trailers are poised to revolutionize diverse sectors. Mass transit operations, ports and even original equipment manufacturers’ manufacturing can benefit from their flexibility and efficiency.

As the world embraces a new energy paradigm, high-pressure gaseous H2 transport provides efficiency, cost-effectiveness and technological advancements to unlock a future where clean energy flows freely. By championing this transformative technology, we can pave the way for a sustainable future powered by the boundless potential of H2. H2T

NOTES

a BayoTech’s HyFill high-pressure H2 transport trailer

b BayoTech’s GTM gas transport module

About the author

JEFFREY MITCHELL is the Business Leader of High Pressure Equipment for BayoTech. He is an experienced sales operations leader and a veteran of the H2 industry. With a proven track record of driving sales excellence and effectively managing commercial operations, Mitchell brings a wealth of expertise to his role. Prior to joining BayoTech, he held commercial leadership positions at Nel Hydrogen and Plug Power where he was responsible for scaling commercial processes, developing demand generation efforts and optimizing sales technology. Mitchell earned a BS degree in entrepreneurship and business management from Quinnipiac University.