Articles

Beyond ammonia: Rethinking the role for ammonia within a vibrant H2 economy—Part 2

H2 Mobility, Transportation and Infrastructure

R. BRUTOCO, World Business Academy, Santa Barbara, California

As the world increasingly seeks sustainable and efficient energy solutions, there is a general consensus that hydrogen (H2) will play a significant role. This makes the question of how this product is best transported not just a technical issue, but also one with profound environmental, economic and geopolitical implications. A growing number of policymakers and ammonia (NH3) industry proponents have recently begun to champion NH3 as the best way to transport H2 and as a viable alternative to pure H2 for various applications, including as a fuel for the maritime industry, an energy storage medium and feedstock for electricity generation.

This perspective touts the potential of “green NH3”—NH3 produced from H2 derived from renewable sources like wind, solar or hydropower—as a more practical and economically viable solution than pure H2. This article examines this narrative, showing how it arises from two sources: first, from a limited perspective on the emerging opportunities provided by H2; and second, from a lack of awareness of recent advances in transport technologies for both gaseous and liquid H2. Based on an in-depth exploration into the production, storage, utilization, safety and economic aspects of both H2 and NH3, this work will show that pure, unadulterated H2 is a superior option in all cases except for the indispensable role green NH3 will play as a primary component in fertilizer production and within several niche markets now served by NH3 derived from non-renewable sources.

Part 1 of this article (May 2024) laid the groundwork for understanding H2’s crucial role in the global energy transition. H2’s unique attributes were explored, including its capacity for zero-emissions energy production, its vital role in transforming hard-to-abate industries, its effectiveness as an energy storage medium and its critical importance in decarbonizing the mobility sector, including cars, buses, trains, heavy-duty trucks and aircraft.

Despite the growing economic feasibility of green H2 production—particularly in areas where extreme climatic conditions already make H2 far less costly today than fossil fuels—Part 1 highlighted the formidable challenges H2 faces in transportation and distribution. These challenges stem primarily from H2’s low energy density and the complexities of cryogenic storage and transportation using conventional shipping methods. The global commitment to H2’s development, evidenced by substantial investments and policy initiatives worldwide, was also discussed. This support reflects the increasing recognition of H2 as a key element in achieving a sustainable and carbon-neutral future, provided its efficient transportation from low-cost production sites to high-demand areas can be realized.

Accordingly, the interest in green NH3 as a proposed medium for H2 transport and distribution was introduced in Part 1, examining both its potential advantages as well as some of the challenges this approach faces. This discussion sets the stage for Part 2 of “Beyond Ammonia,” which delves more deeply into the limitations of NH3 as a H2 carrier and energy source. Finally, this installment explores an intriguing and innovative alternative to NH3 in a development that is poised to significantly impact H2 transport just as major H2 production comes online by the end of the decade in remote locations such as the Middle East, North Africa, Western Australia, Scotland, Eastern Canada, parts of the U.S. and South America. This solution holds the potential to redefine the future of energy transportation.

LIMITATIONS AND DISADVANTAGES OF NH3

While NH3 has important applications in various industries, it is essential to consider its limitations and disadvantages as a potential means for transporting H2 and/or replacement for pure H2. These factors play a pivotal role in assessing the feasibility and suitability of NH3 as an organic H2 carrier and clean energy alternative to pure, unadulterated H2.

Toxicity and safety risks. NH3 is a highly toxic and corrosive substance. While proponents argue that protocols for safe handling are in place, recent incidents underscore the potential dangers. In October 2023, a truck carrying NH3 overturned in Illinois (U.S.), resulting in five fatalities, including two children, and forcing hundreds of residents to evacuate their homes. A similar incident occurred in January 2020, when nearly 800 gallons (gal) of liquid NH3 fertilizer spilled in Illinois, resulting in >80 people being hospitalized with various health issues.13 These events emphasize the safety risks associated with NH3 transport and its potential impact on communities. Considering NH3 as an energy carrier raises questions about whether expanding its production and exposing more areas to such toxicity risks are justified, especially to the extent that safer alternatives are available.

Environmental concerns. NH3 usage in industrial processes contributes to environmental risks, particularly concerning nitrogen oxides (NOX) emissions, which are hazardous, carcinogenic air pollutants that contribute to air pollution and smog formation. The widespread concern about NOX emissions led to the introduction of catalytic converters in vehicles to mitigate these pollutants. If introduced as a replacement for natural gas or coal, NH3 would introduce similar environmental challenges from NOX emissions when burned. In contrast, H2 provides a cleaner alternative for any applications in which combustion is required, emitting virtually no NOX and aligning better with efforts to reduce air pollution and enhance air quality.

Complex H2 conversion. Advocates of NH3 sometimes suggest its use in fuel cells. However, the use of NH3 in fuel cells is very limited due to the tendency of NH3 to severely deteriorate proton exchange membrane (PEM) stack cell structures. Therefore, the only fuel cells in which NH3 is an acceptable fuel are solid-oxide fuel cells (SOFC) and alkaline fuel cells, both of which are predominantly large and have serious drawbacks (SOFCs cannot ramp up and down efficiently, alkaline requires a very large building, etc.). As indicated above, NH3 presents challenges concerning NOX emissions when replacing natural gas or coal in various applications. These emissions are harmful, as evidenced by requiring catalytic converters in vehicles to combat smog. In contrast, H2, particularly when utilized with PEM stack fuel cells, produces zero emissions except for pure water vapor.

While most policymakers and corporate leaders acknowledge H2’s status as the ultimate renewable, clean energy fuel, many argue that NH3 can play a pivotal role in accelerating the critical decarbonization of the economy to combat global warming. However, it is worth noting that NH3’s use as a H2 carrier is frequently overstated because a fundamental technological limitation exists in converting NH3 back into a sufficiently pure level of H2 for use in PEM stack fuel cells. Such conversion to the requisite purity of ≥ 99.7% is not presently economically nor technically feasible for commercial use, despite extensive efforts and investment. Moreover, even if such a process were to be developed in the future, the associated costs are likely to be prohibitively high. Moreover, compared with liquefaction, which takes place at the point of origin where energy costs are low, reconversion of NH3 necessarily must take place at the destination, where energy costs are higher. This complexity underscores the challenges of using NH3 for H2 transport compared to the direct use of H2 in efficient fuel cells.

Multiple cost cycles. Utilizing NH3 as an intermediary for H2 introduces three cost cycles:

- The cost of producing H2

- The cost of converting it into NH3

- Additional costs incurred in converting (e.g., “cracking”) the NH3 back into H2, a process that remains scientifically challenging and currently cannot economically achieve the purity required for PEM stack use.

This redundancy in cost cycles raises questions about the economic viability of NH3 as an energy carrier vs. incurring the single cost of liquefaction and keeping H2 unadulterated from source to end user.

Emissions mitigation and environmental impact. The combustion of NH3 as a fuel source generates emissions, including nitric oxide (NO) and nitrogen dioxide (NO2), that contribute to air pollution, smog and acid rain. While catalytic converters can mitigate these emissions, implementing them on an industrial scale adds further costs. The introduction of such emissions in the context of a transitioning energy landscape inherently conflicts with the broader goals of reducing greenhouse gas (GHG) emissions and environmental harm.

As Hydrogen Europe rightly emphasizes, the costs associated with NH3 cracking, if achievable, would become a significant portion of the H2 delivery costs and effect the cost competitiveness of imported H2:

“The costs of ammonia cracking can form, by far, the largest portion of hydrogen delivery costs (excluding costs of hydrogen itself), drastically impacting the cost competitiveness of imported hydrogen…Therefore, avoiding the dehydrogenation costs altogether, by direct use of ammonia as a fuel or as a feedstock – could, in many cases be the key condition for ensuring the financial viability of importing renewable energy in the form of ammonia.”14

While concerns about the costs of long-distance H2 transportation within the existing maritime system are valid, it is essential to consider these major drawbacks when evaluating the potential of NH3 as a liquid organic energy carrier.15,16

LONG-DISTANCE TRANSPORT OF LIQUID H2

In the pursuit of harnessing H2's potential as a clean energy carrier and combating climate change, the efficient and cost-effective transport of H2 over long distances emerges as a critical challenge. As shown here, H2—an exceedingly light gas with low energy density compared with other fuels—presents unique transportation demands.

According to traditional thinking, long-distance H2 transport must rely on conventional technologies such as pipelines, trucks and ships. Each of these has major limitations for long-distance transport. Pipelines, while efficient, require extensive infrastructure development, complex right-of-way acquisitions and a fixed investment that make them unsuitable for developing new and emerging markets or for trans-oceanic transport. Trucks are only suited to land-based short distances, and generally entail high operating costs. Ships, while capable of long-distance transport, face the challenges noted above associated with boil-off from cryogenic H2 during extended voyages—particularly across warm ocean waters on either side of the equator—and the need for very large storage facilities.

A promising alternative to these conventional modes for long-distance transport is the use of specially designed airships for transport of liquid H2. Airships offer unique advantages that make them a compelling choice for this purpose. These advantages are discussed in the following sections.

Economic efficiency. For decades, airships have demonstrated the potential to carry significant payloads over long distances with remarkable efficiency. Their ability to harness buoyancy, and modern advances in aerodynamics and propulsion, allow them to cover long distances while consuming less energy compared with traditional vessels.

Modern airships are capable of crossing ocean expanses in 1 d–2 d, whereas a ship would require one to two weeks between the same two points. Airships can easily pickup and/or deliver their cargo from inland points, whereas ships can only move between port facilities, thereby requiring multimodal connections, costs and logistics to serve inland locations. Airships can use H2 for lift, enabling them to rise to altitude without expending energy for takeoff like conventional airplanes. Moreover, shipping liquid H2 by sea entails addressing already congested and strategically risky shipping corridors such as the Suez Canal and the Straits of Hormuz. Airships avoid these and other seaborne bottlenecks.

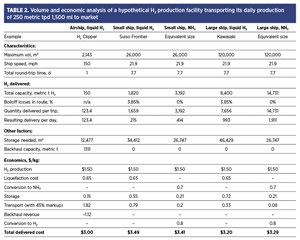

TABLE 2 summarizes a volume and economic analysis of a hypothetical H2 production facility transporting its daily production of 250 metric tpd 1,500 mi to market.17–22 As shown, for such service, airships can transport liquid H2 at a lower cost per kilogram than ships transporting either liquid H2 or NH3.

H2 compatibility. Specially designed airships can safely accommodate cryogenic H2 storage and transport, mitigating the challenges associated with transporting H2 in its gaseous or liquid form via ships. When operated at speeds between 125 mph and 150 mph, any boiloff from the liquid H2 tanks becomes a significant asset. This gaseous H2 can be matched to the fuel required to produce electricity for propulsion from H2 fuel cells. Consequently, the operational costs of airships can be significantly lower for transporting H2 than conventional ships carrying liquid H2 or NH3 products between 500 mi and 3,500 mi, or farther.

Minimal environmental impact. When powered by H2 fuel cells, airships produce no carbon emissions. Their efficient operation, with clean water vapor as their only byproduct, aligns with global efforts to reduce GHG emissions and minimizes environmental impacts.

Flexibility in route planning. Unlike conventional transportation modes, airships are not bound by fixed routes and can access remote or hard-to-reach areas that may lack conventional infrastructure. This flexibility makes them well-suited for transporting H2 from regions with limited accessibility and minimal infrastructure. A H2 delivery airship can transport clean fuel directly from production sources to industrial facilities, power plants or a central storage depot supplying nearby fueling stations and other users. Ports and waterways, runways and airports, or lengthy road or rail networks are unnecessary. This flexibility ensures that airships can deliver fuel even during natural crises, such as in disaster-stricken areas where ports and airports may be inoperative. The dramatic congestion already being experienced by the Suez Canal and the Strait of Hormuz, as well as the supply chain congestion in ports globally, suggests that getting emergency relief supplies anywhere by ship is going to be far riskier than using an airship designed for that purpose.

Safety. Modern airships offer secure and controlled H2 transport without the safety concerns associated with transporting highly toxic NH3. While the Hindenburg tragedy in 1937 raised suspicions about H2’s safety, it is crucial to note that the disaster occurred after 27 yr of accident-free passenger operations, including > 1 MM mi on 590 flights by the Graf Zeppelin between 1928 and 1937. Moreover, the Hindenburg fire was not caused by H2 but rather by the highly flammable aluminum hydroxide paint used on the ship’s surface—a feature that is no longer used in modern airships. In fact, most scientists today understand H2 to be a safer fuel than oil, diesel or natural gas. H2 disperses quickly in the air, aiding in the concentration remaining below 4% (40,000 ppm), the level required for combustion to occur. In comparison, gasoline lingers and is flammable at concentrations as low as 1.4%.

Rapidly scalable. Airships can be designed and scaled according to specific H2 transport requirements, making them adaptable to various cargo sizes and distances. With pre-programmed robotics, airships can be rapidly produced from production facilities in multiple countries.

H2 Clipper, Inc. has focused on this novel approach to long-distance transport of H2 and air cargo since its inception.a Dating back to the company’s earliest patent filing in 2008, its proprietary airship designs are the subject of 12 issued and another 30 pending patent applications that focus on enabling the use of H2 as a lifting gas, a fuel source for propulsion, and as a means for transporting hundreds of tons of liquid H2 per day from remote locations to consumer markets, with the ability to transport freight on the return flight to eliminate “dead heading” costs on the return voyage, which no seaborne ship can avoid.

A fleet of specially designed airships can provide the world’s first point-to-point H2 delivery systemd to supply green H2 from remote production sites, where H2 can be made and liquefied using abundant low-cost renewable electricity, directly to major users or depots located near or within major urban centers and other areas facing urgent clean energy needs. Such airships, by H2 Clipper and others,e have the potential to revolutionize H2 transport, providing a cost-effective and sustainable means of transporting H2 as well as freight across oceans and over long distances. As these technologies continue to evolve and mature, they are expected to play a crucial role in realizing the full potential of H2 as a clean and sustainable energy carrier.

Takeaway: A vision of the future of H2 transport. In the race to combat climate change and transition to a clean energy future, the efficient, speedy, cost-effective and safe transport of H2 has emerged as a critical challenge. H2, often hailed as the ultimate clean and sustainable fuel, possesses unique properties that can revolutionize the planetary energy landscape. It can store intermittent energy—boosting the efficiency and affordability of renewable sources—generate electricity and transform hard-to-abate heavy industries, aviation and long-distance commercial trucking. Green H2, produced using renewable energy sources, stands as the cornerstone in the mission to combat global warming and create a sustainable future.

However, this vision faces a fundamental hurdle: the cost-effective and rapid delivery of H2 from areas where it can be produced most efficiently from low-cost renewable resources to the markets where consumer demand is greatest. NH3, with its established infrastructure and widespread use in various markets, has garnered considerable attention as a potential H2 carrier, as well as an alternative energy source. However, the present analysis suggests that while green NH3 may serve as a valuable resource for specific applications, it presents significant limitations and challenges. The complexities of converting NH3 back into pure H2 and its toxicity, coupled with environmental concerns and economic considerations, raise questions about its viability as a primary H2 carrier, let alone as a substitute for pure H2.

In contrast, specially designed airships like the H2 Clipper are a promising alternative for long-distance H2 transport. Airships offer unparalleled advantages, including superior economics, H2 compatibility, minimal environmental impact, route flexibility, safety and rapid scalability. These qualities position airships as a game-changing solution for the efficient transport of H2 across oceans and over long distances.

The future of H2 transport requires innovative technologies and strategies such as the transport of liquid H2 by airships. While NH3 may have niche applications, airships offer the potential to create a more efficient, safer and more robust H2 transport network. Embracing these innovations is the key to moving beyond NH3 and unlocking H2's full potential as a clean energy carrier and advancing toward a greener, more sustainable biosphere. H2T

NOTES

a In its role as a think tank and action incubator, and in service of its mission to combat climate change and expand corporate consciousness, the World Business Academy incubated the predecessor to H2 Clipper Inc. between 2008 and 2011, when the private corporation was formed. H2 Clipper is now an independent Delaware corporation. For further information, see the H2 Clipper website at https://www.h2clipper.com/solutions/clipper.

d H2 Clipper’s Pipeline in the Sky™

e Warwick, G., “LTA’s large rigid airship gets airborne,” Aviation Week Network, June 14, 2023, online: https://bit.ly/3TlUA4Q. Lighter Than Air (LTA) Research, an airship company founded in 2015 by Google co-founder, Sergey Brin, specializes in large airships designed for humanitarian missions, disaster relief and air cargo operations. In September 2023, LTA obtained a special airworthiness certificate from the FAA to conduct flights with its 123-m (400-ft) long Pathfinder 1 airship. Initially, the helium-filled airship was equipped with two battery packs powering 14 electric propulsion motors, which LTA intends to replace with a hybrid-electric power system using Jet A fuel and 24 batteries to enhance power redundancy. In addition, LTA’s CEO, Alan Weston, has revealed the company’s ongoing development of a H2 fuel cell propulsion system for Pathfinder 1. According to Weston, LTA plans to commence operations initially with gaseous H2 storage, and later transition to a liquid H2 tank. In addition, the company is exploring the potential use of a H2-fueled turbogenerator and has investigated the use of H2 as a lifting gas.

About the author

RINALDO S. BRUTOCO is a pioneering entrepreneur, author, executive and advocate for sustainable business practices and the cultivation of a globally just and sustainable economy. As the Founding President and CEO of the World Business Academy, Brutoco dedicates the Academy’s work to bridging the gap between business innovation and the advancement of global sustainability goals. Brutoco’s career spans various domains, including renewable energy, corporate responsibility and economic policies.

Brutoco's contributions to literature reflect his extensive expertise and commitment to these areas. In 2007, he co-authored Freedom from Mid-East Oil, a comprehensive assessment of the potential options to fossil fuels for simultaneously addressing global energy requirements, climate concerns and social justice issues. He has written extensively on the future role for H2 in addressing these issues, as well as the critical importance of more efficient methods of transporting H2 to enable this. In 2008, he filed for his first of 12 patents on methods for H2 transport, which led to the formation of H2 Clipper, Inc. in 2012. Through 2017, the firm was incubated by the World Business Academy.

A respected speaker and strategic advisor, Brutoco has co-founded a number of other non-profits, including JUST Capital, and counsels with global organizations aspiring to integrate sustainable practices into their operations. Through his writings and advocacy, Brutoco continues to be an influential figure in the movement towards a more sustainable and equitable global economy. The author can be reached at rinaldo@worldbusiness.org.

The World Business Academy is a 501(c)(3) non-profit think tank and action incubator focusing on the role and responsibility of business in relation to solving critical environmental and social challenges. The Academy’s focus on climate change and energy security results from an analysis of the most important threats to human survival and, thus, the survival of business. Formed in 1986, the organization’s 38-yr track record of leadership includes the publication of innovative books, articles, podcasts and videos discussing these topics and other issues of primary importance to society and the business community.

LITERATURE CITED

13 Associated Press, “A truck crash in Illinois kills 5 and forces temporary evacuation over ammonia leak,” National Public Radio, October 1, 2023, online: https://n.pr/3v1L3px

14 Hydrogen Europe, “Clean ammonia in the future energy system,” pp. 30–31, March 2023, , online: https://bit.ly/41lt9Kw

15 Parks, R., “Don’t crack imported blue ammonia back into hydrogen—it raises costs by 50%,” Hydrogeninsight, October 6, 2023, online: https://bit.ly/47Sze3c

16 Clean Air Task Force (CATF), “Techno-economic realities of long-distance hydrogen transport,” September 2023. https://bit.ly/3uVTZN2

17 Ishimoto, Yuki, et al., “Value-chain analysis of liquefied hydrogen, ammonia and pipeline for long distance hydrogen transport,” Institute of Applied Energy, October 12, 2019, online: https://bit.ly/3v4E1QM

18 Ahluwalia, R. K., D. D. Papadias, J-K Peng and H. S. Roh, “Systems level analysis of hydrogen storage options,” Argonne National Laboratory, April 29, 2019, online: https://bit.ly/3NxG8mm

19 Qianqian Song, et al. “A comparative study on energy efficiency of the maritime supply chains for liquefied hydrogen, ammonia, methanol and natural gas,” Carbon Capture Science & Technology, Volume 4, 2022 (https://bit.ly/47TjbCt)

20 Brown, T., “Round-trip efficiency of ammonia as a renewable energy transportation medium,” Ammonia Energy Association, October 2017, online: https://bit.ly/47RofXP

21 Smith, C., A. K. Hill and L. Torrente-Murciano, “Current and future role of Haber–Bosch ammonia in a carbon-free energy landscape,” Energy & Environmental Science, Iss. 2, 2020, online: https://rsc.li/48gHryi

22 Papadias, D. D., J-K Peng and R. K. Ahluwalia, “Hydrogen carriers: Production, transmission, decomposition, and storage,” International Journal of Hydrogen Energy, Vol. 46, Iss. 47, July 2021, online: https://bit.ly/46V4Jsj