Articles

U.S. initiatives, technological advancements and regulatory landscape shape the future of clean H2

Process/Plant Optimization

P. INGRAM, Johnson Matthey, London, UK

Technology has become paramount as the U.S. sets ambitious clean hydrogen (H2) standards to combat climate change. With its promise to fight the climate crisis, bolster energy security and foster economic growth, the potential of generating and utilizing clean H2 is not just promising, it is inspiring.

Zero- and low-carbon H2—pivotal components within diverse solutions crucial for attaining a sustainable and fair, clean energy landscape—are not just a concept, they are a tangible reality that is rapidly growing worldwide. The U.S. is taking proactive measures to expedite advancement by making historic investments in clean H2 production and midstream infrastructure and focused research, development, demonstration and deployment efforts in these pivotal technologies.

The U.S. Department of Energy’s (DOE’s) National Clean Hydrogen Strategy and Roadmap is a comprehensive document that outlines the country's clean H2 initiatives and plans. It explores opportunities for clean H2 to contribute to national decarbonization goals across multiple sectors of the economy, and provides a snapshot of H2 production, transport, storage and use in the U.S. It also presents a strategic framework for achieving the large-scale production and use of clean H2, examining scenarios for 2030, 2040 and 2050.

The Infrastructure Investment and Jobs Act, also known as the Bipartisan Infrastructure Law (BIL), and the Inflation Reduction Act (IRA) have had a profound impact on the U.S. clean H2 market. The BIL, passed in November 2021, authorizes and appropriates $62 B for the DOE, including $9.5 B for clean H2. The IRA, signed into law by President Joe Biden in August 2022, provides additional policies and incentives for H2, including a production tax credit that has further boosted the U.S. market for clean H2.

Overcoming the complexity of clean H2 definitions. Colors have traditionally classified the carbon intensity of H2 as green, blue or gray; however, that classification has expanded to include an entire rainbow of shades. Green H2 uses clean electricity from surplus renewable energy sources, such as solar or wind power, to electrolyze water. Blue H2 is produced mainly from natural gas, using steam and autothermal reforming, which combines natural gas and heated water in the form of steam. Gray H2 is the most common form of H2 production, and is created from natural gas, methane or coal using steam methane reforming (SMR) but without capturing the greenhouse gases (GHGs) produced in the process. Gray H2 is essentially the same as blue H2 but without carbon capture and storage (CCS).

While initially helpful, the color-coding system for H2 can be misleading and does not fully represent the environmental impact of different H2 production methods. It simplifies H2 production methods and their environmental impact, but it has drawbacks. While it helps differentiate feedstock and production methods, the color-coding system can obscure complexities and become irrelevant due to technological advancements. Oversimplification is a crucial issue with this system.

So, where are we now? The answer is unclear and depends on where you live. In the U.S., clean H2 is defined as H2 produced with a carbon intensity of ≤ 2 kg of carbon dioxide (CO2), equivalent to that made at the site of production per kilogram of H2 produced. In the UK, the government’s Department for Business, Energy and Industrial Stategy’s (BEIS’s) Low-Carbon Hydrogen Standard defines low-carbon H2 as H2 that meets a GHG emissions intensity of ≤ 20 g CO2e/MJLHV (megajoule, lower heating value) of produced H2.

The European Union (EU) Commission's H2 strategy defines renewable H2 as H2 produced through the electrolysis of water powered by electricity from renewable sources or through the reforming of biogas or biochemical conversion of biomass. In EU legislation, renewable H2 and H2-derived fuels produced without the use of biomass are referred to as renewable fuels of non-biological origin (RFNBO). The H2 strategy defines low-carbon H2 as significantly reducing full-lifecycle GHG emissions.

Support for H2 production. The regulatory landscape shaping the deployment of clean H2 technologies in the U.S. is still being developed, and federal and state policies, incentives and initiatives aimed at promoting H2 production, infrastructure development and market adoption are still being finalized.

The IRA offers a H2 production tax credit of up to $3/kg, leading to a notable 50%–75% decrease in anticipated H2 production costs. This tax credit is crucial for fostering the substantial growth of H2 production, especially given its high price compared to alternative fuels. Proposed regulations released by the U.S. Treasury Department and Internal Revenue Service (IRS) in late 2023 outline the parameters for credit eligibility, with the highest credit awarded to H2 production processes that generate minimal or no carbon emissions throughout the entire value chain (green H2).

To qualify for the tax credit, green H2 production must meet rigorous criteria regarding additionality, deliverability and time matching, particularly concerning the significant electricity consumption during production. While these criteria ensure the produced H2 is green, they may also expand project scope and capital costs, reduce efficiency and relocate much of the production away from high-demand areas.

The additionality provision encourages green H2 initiatives to utilize renewable energy from recently established facilities that are < 3 yr old. Projects opting for new renewable energy sources must either incorporate the facility into their project plans, increase capital costs, or engage a third party to construct and operate a new facility, heightening counterparty risk.

The technology behind clean, sustainable H2 production. Traditional H2 production relies on SMR, converting natural gas into H2 and CO2. Integrating CCS technologies ensures responsible CO2 management through geological storage or repurposing within existing oil and gas infrastructure. This aligns with sustainability goals and future emissions standards.

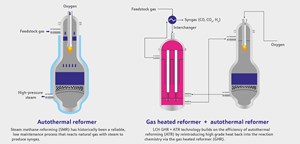

However, for more efficient and cost-effective low-carbon H2 production, autothermal reforming (ATR) and ATR coupled with gas heated reforming (GHR) offer promising alternatives (FIG. 1). These proven processes provide enhanced efficiency and flexibility compared to conventional SMR, making them viable options for large-scale H2 production.

In the ATR process, a blend of hydrocarbons (typically natural gas) and steam enters the reformer reactor. Unlike conventional SMR, ATR involves simultaneous partial oxidation and steam reforming reactions facilitated by adding oxygen or air. Inside the reactor, hydrocarbons partially oxidize with oxygen, generating heat and carbon monoxide (CO). Subsequently, steam reacts with the remaining methane, producing additional H2 and CO.

This dual-reaction mechanism enables efficient H2 production while generating the heat required for the endothermic steam reforming reaction. Unlike SMR, ATR does not need external heat input—therefore, no CO2 is generated from combustion. Instead, all CO2 is produced internally, simplifying capture and reducing costs, especially in markets where steam holds value.

Integrating GHR enhances the ATR's efficiency by utilizing the heat generated for reforming reactions. This boosts overall energy efficiency, requiring less natural gas per H2 unit and achieving lower carbon intensity with similar capture rates.

Combining ATR, GHR and CCS technologies can capture up to 99% of CO2, producing low-carbon H2. The core of the process lies in the GHR-ATR reforming block, maximizing feedstock efficiency through efficient energy transfer. Additionally, all CO2 remains within the product stream, making it easily removable using standard industry techniques. This capability reduces system costs and footprint, facilitating deployment on existing sites and lowering the levelized cost of H2 (LCOH).

In the U.S., ATR presents numerous advantages over conventional SMR methods. When coupled with GHR technology, ATR becomes exceptionally adaptable, catering to the availability of local geological resources. Whether in urban or remote areas, ATR optimizes feedstock utilization, enhances H2 production efficiency, reduces the LCOH, mitigates environmental repercussions, and establishes itself as a financially feasible and environmentally sound option for large-scale, low-carbon H2 production today. H2T

NOTE

a Johnson Matthey’s LCH™ GHR + ATR technology

About the author

DR. PHIL INGRAM is the Managing Director, Low-Carbon Hydrogen and Ammonia, at Johnson Matthey. He has spent most of his career in H2 and syngas, starting out in catalyst development for steam reforming and ATR applications. He has spent the last 17 yr in a variety of commercial roles in catalyst sales and technology licensing in the Americas and Europe, always with H2, ammonia and methanol as the central pillars. Dr. Ingram joined the Low Carbon Hydrogen team in October 2021, motivated by the transformative opportunity that the energy transition presents.