Articles

Automation is key to an effective H2 value chain

Digital Technologies

V. CONSTANTIN, Emerson, Bucharest, Romania

Hydrogen (H2) has been around since the universe began and has been used industrially on a large scale since the early 1900s. For the most part, these operations have been limited to ammonia production and oil refining, with each facility manufacturing gray H2 by reforming the methane found in natural gas. In these applications, the H2 was necessary as a chemical feedstock, and the carbon dioxide (CO2) released to the atmosphere was not closely monitored.

However, reforming is an energy-intensive process. A typical steam methane reformer (SMR), which is a major process unit, easily consumes half as much natural gas for fuel as it reforms. The vast bulk of H2 produced today still uses this approach.

Nonetheless, things are changing quickly, and H2 is emerging as a non-carbon intensive energy source, and as an energy storage mechanism that is useful for traditional applications and new highly sustainable products and processes (e.g., steel production, fuel cell vehicles). So, the question is: Can we integrate existing production along with new and emerging technologies into one comprehensive value chain to maximize efficiency, while minimizing environmental effects?

Steps to link the chain. The first step is finding mechanisms to increase existing gray H2 capacity, so those operations become links in the supply chain. Many value the ability to sell the excess H2 produced, but the problem of CO2 emissions remains and must be addressed. SMR and similar reforming methods produce a stream of high-purity CO2 during the carbon separation step, which is a prime candidate for carbon capture, use and storage (CCUS). If CCUS is added to the process, it becomes blue H2, which is much higher on the environmental responsibility scale and necessary in any CCUS value chain. However, the process still uses fossil fuel as the feedstock, and only a portion of the CO2 can be captured.

Green H2, made via electrolysis using renewable power, can be used for any purpose, replacing gray and blue H2 in many applications if sufficient volumes are available. Electrolyzers are produced in many sizes, making them easy to place wherever sufficient renewable power infrastructure is present. Looking ahead, green H2 can support energy security anywhere in the world since it does not depend on natural gas availability. It can also create the means for economic growth, as countless new jobs are emerging from its development.

While we understand its value, we are still in the early days of H2 development. Compared to oil and natural gas distribution (available virtually anywhere on the planet), H2 still exists in limited pockets. To a distribution center wanting to use H2 for powering its forklifts, or gas utilities providing H2-blended gas to fuel consumer appliances, the question becomes: Where can I get H2?

Similarly, a facility wanting to produce green H2 must ask: Is there a high-value application for what we are producing? In virtually any area, H2 can be added to natural gas distribution. This is a fairly low-value option in terms of profitability, but it offers a positive environmental impact. This approach makes no environmental sense for gray or blue sources, but it is viable option for surplus green H2.

A better alternative is for green H2 producers to partner with chemical plants, stationary fuel cell power systems and vehicle operators. These applications have higher value and environmental impact. However, the means must be available to make these applications possible, and transport may be required. This integration of production and use is rapidly emerging globally through private and government partnerships to create industrial clusters or hubs.

Comprehensive solutions for joining processes. The hydrocarbon value chain has been evolving for more than a century, but it has often been dependent on a mix of manual and automated operations for production, storage and transportation. Today, sophisticated technologies are available to fully automate these processes, but they must be chosen and applied carefully.1

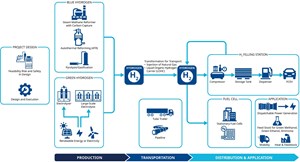

The H2 value chain will have some similarity to natural gas, but in many respects, the products are much different. The H2 value chain will include many different users that utilize it differently. This will likely include people with little or no direct experience with H2, so training will be of critical importance (FIG. 1).

So, what will this new value chain look like? It must comprise three areas:

- Production: Whether green or blue, produced by electrolysis or through SMR with carbon capture, H2 production requires robust control systems to ensure reliable, safe and seamless operations.

- Storage and transportation: The focus in this area must be on reliability and safety, using leak detection systems and other technologies to protect people, the environment and valuable H2

- Distribution and end-use applications: Distribution will depend on rail and trucks, at least early on, but strategic pipelines should develop quickly. Automation products are available to support stationary and mobile vehicle fuel cells, plus utility-scale power generation as turbines are newly manufactured or modified to burn a mix of natural gas and H2, and eventually pure H2.

Meeting these objectives calls for various automation technologies and products, ideally purchased from a partner with domain expertise and experience in the process industries. The selected partner should have extensive experience in process measurement and control, as well as safety and regulatory compliance, enabling it to work with end users to develop and deploy these innovative technologies.

The selected partner should be able to provide safety solutions and systems, as these are crucial in the types of industries where safety is a top priority, such as H2. This includes technologies for emergency shutdown and safety instrumented systems, which are important in H2 facilities. Ideally, the selected partner would also provide:

- Advanced process control (APC) solutions, including asset optimization software, because combining APC with basic process control systems will improve performance and efficiency by optimizing operations.

- Instrumentation and measurement solutions are needed in the context of H2 production for monitoring and controlling process variables, such as pressure, temperature, flow, level and other parameters.

- Control valves and accessories for use in H2 production and distribution systems to control flows and ensure optimal performance.

- Energy management solutions to help end users optimize energy usage in H2 production facilities, contributing to overall efficiency and sustainability.

End users can deploy these types of solutions to drive operational excellence, reduce production variability and ensure efficient production planning. These solutions are essential to accelerate the development of the H2 value chain across all sectors and increase the efficiency of massive H2 production plants.

If end users and their vendor partners work together to address global energy challenges by linking an effective H2 value chain, the transition to a cleaner, safer and more sustainable global energy ecosystem will accelerate.H2T

LITERATURE CITED

1 Emerson, “Accelerating the transition to a hydrogen future,” online: https://www.emerson.com/en-us/esg/environmental-sustainability/hydrogen-value-chain

About the author

VERONICA CONSTANTIN is the Vice President of Global Sustainability for Emerson, and a 26-yr veteran of the company’s European operations. In her current role, Constantin leads the global sustainability strategy for Emerson, enabling customers to meet their environmental, sustainability and decarbonization goals. She joined Emerson in 1997, ascending through various roles, including Vice President for European strategic accounts, general management and sales. Constantin earned an MS degree in electrical engineering from the Polytechnical University of Bucharest.