Articles

Under pressure: Navigate the complexities of H2 blending

Special Focus: Process/Project Optimization

A. RICHHARIYA, Emerson, Calgary, Canada; and L. GONZALEZ, Emerson, Houston, Texas

The world energy economy is changing and quickly putting increased pressure on natural gas producers and transporters around the globe. Civil unrest has increased the instability of natural gas supplies, while a global push toward sustainability is driving a trend toward renewable options at a previously unheard-of rate. These market forces are not going away anytime soon, and companies have been looking for ways to react.

One of the primary ways natural gas companies are navigating market shifts is by blending hydrogen (H2) with natural gas. H2 can be created sustainably anywhere in the world, and blending is a process that can evolve gradually, giving operations time to safely transition to new processes and expectations.

However, with any emerging process comes new uncertainty. Many operations that support H2 blending are neither fully defined nor fully tested. As a result, while H2 blending presents an incredible opportunity for growth, it simultaneously generates new risks. The companies that win the future of gas production and transportation will be those that are both bold enough to chase modern, field-proven technologies, and wise enough to build their operations on a solid, sustainable foundation.

Data is key. Success in H2 blending is possible and the rewards can outweigh the risks. The key to achieving that success comes via holistic automation modernization focused on breaking down data silos from end-to-end. Today’s most successful companies embrace technology platforms like the authors’ company’s next-generation architecturea vision that seamlessly move data from the intelligent field devices through the edge and into the cloud to unlock the visibility and analytics necessary to refine H2 blending operations for increased safety and efficiency (FIG. 1).

Fortunately, modernization is not an insurmountable obstacle. Companies that know where modernization is most critical can begin making targeted investments—whether or not they are already planning to blend H2—to build a foundation of secure connectivity that will carry them confidently into the new energy economy.

Make the most of the intelligent field devices. As companies begin blending more H2 with natural gas in their pipelines, legacy technologies will not be adequate to monitor and maintain safe, efficient and secure operations. Companies running decades-old equipment will struggle to handle the plethora of new data necessary for more complex operations. There is also increased exposure to cyber-attacks since older technologies do not offer the resiliency available in today’s modern solutions.

Modernizing measurement. First, operations must ensure they have the right onsite equipment in place. They will require sensors and analyzers capable of measuring the H2 component, natural gas component and blended product to ensure blending is proceeding according to specification.

Operations must also ensure the material grade in their sensors is appropriate for H2. Multivariable sensors with a stainless-steel diaphragm will allow H2 to pass through. Updating to modern sensors with gold plating will significantly improve performance.

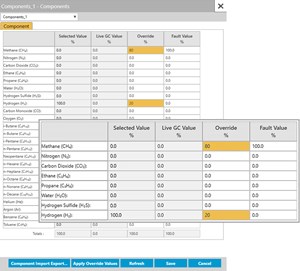

Operations will need modern gas chromatograph (GC) analyzers to measure the precise amount of H2 in the natural gas stream. Some legacy GCs have limitations on the percentage of H2 they can measure in a blended product. Modernizing will help ensure devices work—and will continue to work—with current operations as they scale up the percentage of H2 in the blend. Additionally, when selecting a meter (whether it is Coriolis, ultrasonic or turbine), companies must ensure the device offers the correct options for the selected flow and expected fluid composition.

Up-to-date calculation engines. Although natural gas has always contained a percentage of individual gases mixed, H2 has typically been a small percentage of that mix. As H2 blending increases, so too will that percentage; and, as the composition changes, the old algorithms will no longer apply. This change is reflected in the American Gas Association’s (AGA’s) equations for calculating properties—including density, energy content and standard volume—when blending significant amounts of H2 into natural gas. As a result, in addition to adding new measurement devices, it will also be important for companies blending H2 with natural gas to modify the devices receiving data from sensors.

One of the recommended calculations, AGA Report 8 Part 2,1 is unavailable on many of the older flow computers and remote terminal units (RTUs). Operations must replace these assets with ones that support new algorithms to calculate the standard volume, density and energy content of the blended product. To meet their current goals and prepare for the future, companies should look for RTUs and flow computers that can keep algorithms up-to-date across their lifecycle. The best automation suppliers will offer the most current algorithms and will provide extensive support so companies can better manage and maintain their operations when regulations and equations require modifications (FIG. 2).

Companies should also prioritize RTUs and flow computers that integrate seamlessly with the automation technologies they already have in place. Today’s best solutions simplify connectivity to onsite devices, with no need for complex and fragile custom engineering. The mapping of sensors and GCs to flow computers and RTUs is much easier today with vendors offering a more standardized approach, making integration less complex and the adoption of new automation a more seamless experience.

Edge computing to enhance operations. Modern measurement devices are critical for securely delivering the precise data necessary for primary operation across a site. However, because H2 blending is a new technology, operations must also collect data and analyze trends over extended time periods to help dial in their best production variables. Advanced analysis requires greater data granularity for a longer period. As a result, most operations performing H2 blending will require a solution for high-resolution data collection.

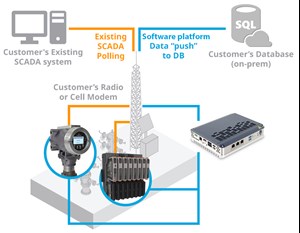

Modern edge computing devices are the perfect solution for entry into a high-level collection of high-resolution data. Edge devices are installed alongside site connections and connected to flow computers and RTUs. The data in edge devices can be processed through analytics at the edge, non-invasively adding value for enhanced insight into operations (FIG. 3).

For example, consider an operation that wants to track and trend performance of its H2 blending over many months and under a wide variety of environmental variables, but with a supervisory control and data acquisition system that is at capacity. Using an edge analytics device, that operation can still collect the necessary granular, high-resolution data and feed it into powerful analytical tools to expose long-term trends, all without disturbing their existing network.

Harnessing the cloud to get more out of data. To further reduce data silos, operations pursuing H2 blending will harness their edge technologies to push critical data from the field into the cloud for deeper investigation into the performance of their sites. Consider an operation that runs a traditional natural gas pipeline to a community. The company will likely have been running that pipeline for many years and will understand the difficulties as seasons change and demand fluctuates. Increasing pressure to pump more gas in the winter and dialing back pressure in the summer will likely be routine operations.

However, if that company begins blending H2 into the natural gas it sources, operations begin to change drastically. The heating value of H2 is lower than natural gas, so the company will need to pump more gas through the pipeline to meet demand. H2 is the smallest molecule on Earth—its size means it can squeeze into tiny spaces in certain steel alloys in a way that natural gas cannot. H2’s unique properties can cause embrittlement, making the metal more likely to crack or corrode.

If the operation can collect data at the edge for an extended period and move that data seamlessly to the cloud, it can be used to train modeling systems. Cloud simulation technologies can build functional models in a digital twin to test against a wide range of variables as operators increase and decrease H2 ratios. Using replicas of the pipeline operation built in the cloud, personnel can test many different operating scenarios to see which future setpoints will best deliver on their contractual obligations. Because the testing is not performed on live equipment, it has no impact on daily operations.

Those same models used to identify the ideal H2/natural gas ratio for any operation can also be used to test other operating strategies, or to test new equipment well in advance of installing it onsite. Even when simulations are not being used to change operations, they can be used to train operators—both new and experienced—on daily operations. Trainees will see the same interfaces they will use in the field, helping them manage normal and abnormal operations more effectively from their very first moments onsite.

Choosing a cybersecure and open architecture. Advanced operations are only possible when data is up-to-date. When an organization’s architecture is riddled with data silos, edge analytics fail to reflect real-world conditions and simulations quickly deviate from actual operating conditions. By selecting RTUs, flow computers, edge devices and other automation technologies built on open architecture standards, operations can avoid the data silos created by proprietary vendor technology.

Technology built on protocols like DNP3, MQTT and OPC UA empower users to utilize their data in the resources they already have internally without being tied into proprietary software or programming environments (FIG. 4).

Users can more easily move data to any point in their enterprise to be used by cross-functional teams collaborating to optimize efficiency and solve problems. Open protocols offer the best mix of flexibility, interoperability and security. For example, DNP3 Secure Authentication Version 5 provides secure connectivity between devices and host systems by using a complex encrypted key, preventing man-in-the-middle attacks from interfering with operation.

Successful futures are built on solid foundations. Navigating the new energy economy will require bold steps, but those bold steps do not have to be risky gambles. Modern technologies—including edge solutions and software—can be used alongside existing RTUs, flow computers and other devices to gain the data mobility necessary to design, improve and maintain operations. As companies begin these modernization efforts, a roadmap with a shorter- or longer-term goal of seamlessly integrated solutions designed from the ground up will allow the flexibility to adopt technologies sooner with reduced risk.

Companies that adopt this strategy will be far less likely to “rip and replace” their solutions every time a new regulation or new operating strategy forces operational changes. The foundations that companies build today will define their future operations.H2T

NOTES

a Emerson’s Boundless Automation™

b Emerson’s FBxEdge Software Platform

LITERATURE CITED

1 American Gas Association (AGA) Report 8 Part 2, “Thermodynamic properties of natural gas and related gases GERG—2008 equation of state,” April 2017.

About the authors

ABHISHEK RICHHARIYA is Emerson’s Product Manager for flow computers and has more than 18 yr of experience in the automation industry. He has spent more than 10 yr in oil and gas custody transfer flow measurement, with the last 5 yr in his Product Manager role. Richhariya earned his BE degree from Rajiv Gandhi Proudyogiki Vishwavidyalaya in Bhopal and his executive MBA from the SP Jain School of Global Management in Dubai.

LAURA GONZALEZ is Emerson’s Product Manager for edge and application solutions. She has been with Emerson for 9 yr and has extensive experience working with various legacy RTUs and RTU platforms. Gonzalez earned a BS degree in chemical engineering from Texas A&M University.