Articles

H2Tech: Tech Spotlight

T. CAMPBELL, Managing Editor

H2 EQUIPMENT

Landi Renzo launches new mechatronic H2 pressure regulator

Landi Renzo and Bosch have begun developing advanced electronic pressure regulators for mid- and heavy-duty commercial vehicles with H2-powered internal combustion engines (ICEs). The two companies seek to produce and commercialize H2-based fuel systems featuring a next-generation mechatronic pressure regulator that supports the carbon-neutral operation of commercial vehicles.

The pressure regulator decouples the accumulation and combustion chambers' fuel introduction systems. A simple and robust mechanical regulator was previously sufficient to manage this function; however, the zero-emissions fueled engines of the future will require pressure regulators that are robust and reliable, unlike the unpredictability performance characteristics of the former regulators.

The EM-H mechatronic pressure regulator ensures optimal management and calibration of H2 delivery pressure according to the vehicle’s requirements, conveyed accurately and efficiently. Designed and manufactured in Italy, two phases govern the functionality of the EM-H regulator: a mechanical input stage that reduces pressure from high to medium, and a subsequent entirely electronic stage that lowers pressure from average to the desired value. The system features special valves to protect the pressure regulator and downstream fuel line.

For more information, visit https://landiusa.com/products/

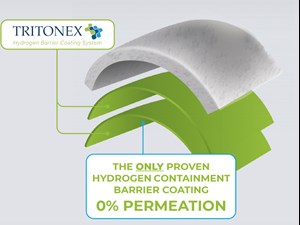

Triton Norway unveils impermeable H2 barrier coating system

A group of scientists at Triton Norway have combined nanotechnology, electrochemistry and material science to contain H2 and help unlock its vast potential for our planet. The scientists have created a 100% impermeable barrier that does not react to H2. The team has harnessed the enigmatic secrets of nano-sequencing and electro-osmosis and developed the Tritonex Hydrogen Barrier Coating System (HBCS).

Tritonex is electrically inert and does not react to chemicals, so it stops corrosion entirely. Tested to temperatures of > 1,000°C, Tritonex is designed to withstand extreme temperature variations and is remarkably flexible, with the ability to follow the thermal expansion and contraction movements of pipes and storage vessels. It is non-toxic, ensuring safety in handling, and its smooth surface also provides flow assurance.

Its unique properties, including barrier efficiency, make it a valuable tool for the H2 infrastructure, storage and transport sectors. As a universal solution, it is applicable across substrates from steel to composites, carbon fiber, plastic and even rock.

The Tritonex can be applied manually and robotically, making it a boon for original equipment manufacturers and field retrofitting. Tritonex has shown zero H2 permeation in rigorous tests, attaining its ISO 17081:2014 certification—the only barrier coating to hold this ISO, to date—a feat that cements its place as a leader in containment technology.

For more information, visit https://tritonnorway.com/our-solutions/

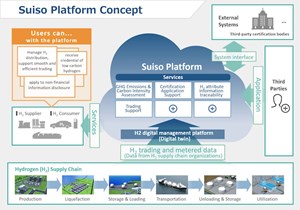

Kawasaki to start demonstration tests for H2 distribution visualization platform

Kawasaki Heavy Industries has announced that it plans to start demonstration tests in April for its Suiso (H2 in Japanese) Platform, a digital management system developed to enable centralized H2 distribution management and support H2 trading domestically and internationally.

As the practical application of H2 supply and utilization moves forward to realize a carbon-neutral society, H2 trading is expected to increase internationally. However, regarding actual H2 supply chain operations, H2 distribution is geographically and temporally extensive—including the diversification of production sources and international transportation—and the players involved are also diverse. As a result, the management of information on attributes such as sources of H2 production, distribution routes and emissions of greenhouse gases (GHG), including CO2, in each supply chain process becomes highly complex.

Accordingly, a framework enabling digital management and visualization of the entire supply chain—from production to utilization—is essential to ensure H2 traceability.

In future H2 trading, proving H2 is low-carbon will be highly important. Assessments and certifications of low-carbon H2 ensure transparency and reliability for H2 business operators to engage in low-carbon H2 trading. Moreover, they enable H2 users, including companies pursuing non-financial information assessments and disclosure, to confidently use H2 as a reliable means to decarbonize their businesses.

Kawasaki is building a digital platform and planning-related services for H2 suppliers, business operators and H2 users to offer efficient centralized management of data and information such as sources of H2 production, GHG emissions and trading. These will ensure traceability for low-carbon H2, visualize complex H2 distribution and facilitate smooth H2 trading.

More specifically, Kawasaki plans to launch the following four services and expand its service offerings:

- Ensured traceability by strengthening the chain of custody through the digital management of attribute information such as H2 locations and carbon intensity

- Assessment and management of GHG emissions and carbon intensity

- Support for low-carbon H2 certification application

- Support for H2 trading activities.

Kawasaki has already completed the platform’s basic design. To verify the effectiveness of the services, the company plans to start demonstration tests in April for the geothermal origin H2 SC Project in Oita undertaken by Obayashi Corp. The tests will enable quicker identification of problems with the system and functional improvements, thus facilitating efficient development of the system’s detailed design. Kawasaki plans to complete the design and development of the platform in 2025, followed by customer assessments, and will launch for commercial use around 2028 by a wide range of industry players involved in H2 supply chains.

For more information, visit https://global.kawasaki.com/en/industrial_equipment/

Gore inks agreement to develop polymer electrolyte membranes for H2 fuel cell systems

Hyundai Motor Co., Kia Corp. and W. L. Gore & Associates have signed an agreement at the Mabuk Eco-Friendly R&D Center, Korea, to collaborate on developing advanced polymer electrolyte membranes (PEMs) for H2 fuel cell systems.

The joint effort will encompass key aspects of PEM development. The ultimate goal of this collaboration is to develop an advanced PEM for next-generation fuel cell electric commercial vehicles.

A H2 fuel cell utilizes a PEM to conduct protons between two electrodes. The PEM blocks the direct combination of incoming H2 and oxygen gases, facilitating the selective conduction of protons and, in turn, generating an electrical current to power a vehicle. PEM technology plays a crucial role in determining the performance and durability of the fuel cell system.

For more information, visit https://www.gore.com/products/categories

H2 PRODUCTION

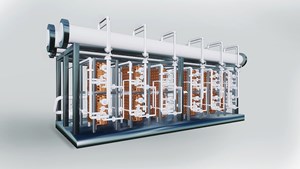

Chiyoda Corp. and Toyota jointly developing a large-scale electrolysis system

Chiyoda Corp. and Toyota Motor Corp. have agreed to jointly develop a large-scale electrolysis system, construct a strategic partnership and sign a basic cooperation agreement. The goal is to contribute to achieving government targets to introduce electrolysis equipment to Japan and overseas as part of the basic strategy on H2 formulated by the government.

The production technologies for electrolysis cell stacks using the fuel cell technology held by Toyota and the processing plant design technologies and large-scale plant construction technologies held by Chiyoda will be brought together to develop a competitive large-scale electrolysis system. Specifically, the goal is to develop a small electrolysis system with high H2 production efficiency.

To respond to the various needs of customers, 5 MW-class equipment will be used as the basic unit (floor area: 2.5 m x 6 m, with a H2 production capacity of approximately 100 kg/hr) for development, and will be combined to create a standard package, allowing the construction of large-scale electrolysis systems.

The merits of this equipment include the fact that it only takes up about half the floor area of conventional equipment and offers ease of maintenance while allowing easier shipping, shortened onsite construction times, and lower civil engineering and construction costs. Toyota's expertise in industrial products and Chiyoda's expertise in plant engineering will be combined and optimized, allowing benefits such as lower costs, increased production efficiency and more consistent quality for the electrolysis systems required to produce green H2.

With the signing of this basic cooperation agreement, introducing an electrolysis system in the H2 park at the Toyota Honsha Plant will start in 2025. It will be expanded to the 10-MW class and used for verification and development. Any further developments will be released as they happen.

For more information, visit https://www.chiyodacorp.com/en/service/

Titanium oxide material lets sunlight drive green H2 production

A team of materials scientists, led by distinguished professor Dr. Michel Barsoum and researcher Dr. Hussein O. Badr has developed a breakthrough titanium oxide nanofilament material that can efficiently split H2 from water using only sunlight. In tests, the material outperformed leading commercial photocatalysts by a factor of 10 and remained stable for more than 6 mos. The discovery could uncouple large-scale production of H2 from the use of fossil fuels.

H2 APPLICATIONS INNOVATION

FedEx Express tests H2-powered technology with HYVIA van pilot in Utrecht

FedEx Express Europe has begun a trial of a H2-powered vehicle in its pickup and delivery operations in Utrecht, Netherlands. This is the first time FedEx Express has tested H2 technologies in Europe to gain early insights into new solutions that will help decarbonize hard-to-abate sectors, with the potential for application in a transportation network.

HYVIA manufactures the Renault Master Van H2-TECH as a joint venture between Renault Group and Plug. It can be refueled in under 5 min with 6 kg of H2 gas, which generates electricity through a 30-kW fuel cell, providing power to the eMotor. The fuel cell recharges an onboard 33-kWhr lithium-ion battery, enabling pure electric range capacity, if required.

FedEx Express is piloting the van in daily operations for 2 wk, where it will perform parcel pickups and deliveries in the Utrecht area. With a size and specification comparable to the current fleet, the H2-powered van has a range of 400 km—well-suited to the range requirements for a typical daily route. The vehicle will refuel nearby at Greenpoint, an existing 700-bar H2 refueling station approximately 15 km from the FedEx facility.

For more information, visit https://www.fedex.com/en-us/about/company-structure.html

ZeroAvia wins CEC grant to develop high-efficiency liquid H2 refueling trucks

ZeroAvia has been awarded $3.25 MM in funding by the California Energy Commission (CEC) to develop a first-of-a-kind mobile liquid hydrogen (LH2) refueling truck for heavy-duty applications, including aviation and maritime. Funding for the project comes from the Gas R&D Program administered by the CEC and authorized by the California Public Utilities Commission.

ZeroAvia will design, build and demonstrate a 10,000-liter (l) mobile LH2 refueler with sufficient flowrates to refuel in a similar time as traditional jet fuel refills. Hitting this ambitious target will support H2-powered aircraft meeting tight turnaround windows, especially in regional transport.

The LH2 refueler will also improve energy efficiency in LH2 applications, reducing H2 boil-off to less than 0.1%/d. ZeroAvia is developing H2 fuel cell propulsion to tackle the climate impact of aviation. The company plans to support passenger and cargo flights by the end of 2025 with its first H2-electric engines (ZA600) for 9–19 seat aircraft using gaseous H2 storage.

To scale H2 engines to larger commercial aircraft and to enable longer ranges across all aircraft sizes, cryogenic LH2 must be used to reduce the size and weight of the fuel storage systems. ZeroAvia is already developing its larger ZA2000 engine family: the first high-power ground tests of the fully integrated electric propulsion system were conducted earlier this year. These larger aircraft—such as the Dash-8-400 76-seat aircraft ZeroAvia is working on with Alaska Airlines and other partners—will require up to 1 t of LH2 storage onboard to support up to 700 nautical mile range, with a 2027 target launch.

The CEC-funded project advances the commercial viability of LH2-fueled aircrafts by supporting advancements in energy performance, cost efficiency and refueling speed. The technology also has potential application in other segments of the transportation sector, including road freight and maritime.

For more information, visit https://zeroavia.com/products-services/

Sirius Aviation AG unveils H2 VTOL aircraft: Sirius Jet

Swiss aviation startup Sirius Aviation AG has unveiled the Sirius Jet—a H2-powered vertical take-off and landing (VTOL) aircraft designed and built in collaboration with BMW's Designworks and Sauber Group. This marks a significant milestone in sustainable aviation and highlights Sirius Aviation AG's steadfast commitment to innovation, sustainability and safety.

The Sirius Jet is a high-performance, zero-emissions VTOL aircraft propelled by a H2-electric propulsion system. Leveraging jet aerodynamics with airplane and helicopter versatility, it achieves extended flight distances, impressive speeds and high altitudes at near-silent levels.

In 2025, the Sirius Jet will take flight in two versions: Sirius Business Jet, tailored to private jet needs, and Sirius Millennium Jet, crafted for commercial aviation. The specifications of the Sirius jets are:

- Sirius Business Jet: A zero-emissions, H2-powered VTOL business jet featuring a 1,150-mi flight range, a cruising speed of 323 mph, an altitude capability of 30,000 ft, ultra-quiet noise levels of 60dBa and accommodations for three passengers.

- Sirius Millennium Jet: A zero-emissions, H2-powered VTOL commercial aircraft offering a 650-mi flight range, a cruising speed of 323 mph, an altitude capability of 30,000 ft, a sound footprint of 60dBa and accommodations for up to five passengers.H2T

For more information, visit https://siriusjet.com/sirius-jet/