Articles

H2Tech: Tech Spotlight

H2 EQUIPMENT

CuraScientific announces new H2 fuel cell product for 2025

CuraScientific Corp.’s wholly-owned subsidiary, Sustainable Energy Group (SEG), is developing a low-cost hydrogen (H2) fuel cell for residential solar batteries. With more than 20 yr of experience in providing solar products and services, SEG has established a reputation for integrity and innovation in the alternative energy industry.

The new product is poised to revolutionize residential solar systems by offering the ability to charge solar batteries at any time during the day, regardless of weather conditions or light availability. This technology combines battery storage with H2 fuel cells, providing consumers with a reliable and cost-effective solution for transitioning to a 100% clean electricity grid. SEG has set the summer of 2025 as the target for the rollout of its first-generation product for residential use.

For more information, visit https://sustainableenergygroup.com/

Intelligent Energy unveils new H2 fuel cell

Intelligent Energy (IE) has unveiled a new, compact H2 fuel cell system. As the world searches for a truly sustainable, zero-emissions mobility solution, fuel cells have the potential to help overcome some of the challenges associated with battery electric vehicles (BEVs), namely a dependency on limited natural resources and electric grid capacity, long battery charging time and limited vehicle range. Fuel cells can also be as cheap to manufacture as internal combustion engines (ICEs) and can be produced from recycled and recyclable materials.

IE’s patented IE-DRIVE system has been designed to give passenger car manufacturers direct access to the smaller, more powerful, turnkey and commercially-viable H2 fuel cell solution required to make zero-carbon emissions mobility a global reality in the passenger car market. The single stack platform was recently revealed during a launch event at IE’s Loughborough headquarters where it powered a sports utility vehicle (SUV) provided by Changan UK.

The specification of the IE-DRIVE platform provides significant benefits when compared to other fuel cells that have been developed by large automotive groups and their third-party fuel cell suppliers. In its configuration, IE’s IE-DRIVE fuel cell stack is capable of 157 kilowatts (kW) of gross electrical power.

For more information, visit https://www.intelligent-energy.com/our-products/ie-drive/

Verde Hydrogen unveils VERDE Analytics Platform V2.0

Verde Hydrogen has announced the launch of a new multi-stack intelligent control system, the Verde Analytics Platform Ver. 2.0. This new control system will help manage H2 production efficiency, scalability and intelligent management of multi-stacks. The multi-stack intelligent control system is highly scalable, enabling H2 production to achieve the seamless transition from hundreds of megawatts to gigawatts.

The innovative rotation design not only ensures maximum power and utilization, but also enables batch maintenance, thereby extending the service life of the electrolyzer and reducing maintenance costs. The highlight of Verde Analytics V2.0 is its ability to perform predictive maintenance scheduling and operational optimization, and to conduct real-time data analysis, thus ensuring the continuity and efficiency of H2 production.

For more information, visit https://verdehydrogen.com/verde-analytics.html

Open Hydrogen Initiative unveils open-source toolkit to measure H2’s carbon intensity

The Open Hydrogen Initiative (OHI) has released a first-of-its-kind, open-source toolkit aimed at furthering transparency into the environmental impact of H2 production. This toolkit was unveiled by founding partners GTI Energy and S&P Global Commodity Insights, and a cohort of collaborators from diverse fields of industry, academic and scientific experts globally. This toolkit for measuring carbon intensity is available on an open-source basis.

The OHI toolkit has been demonstrated in 13 industry projects spanning two continents and contains detailed analyses for more than 200 technologies across 270 countries and regions. It is one of the most comprehensive open-source H2 lifecycle assessment toolkits available to the market, setting a new standard for quantifying trust in data.

For more information, visit https://www.gti.energy/ohi/lca-toolkit/

H2 PRODUCTION

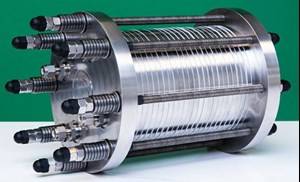

Ionomr Innovations releases iridium-free catalyst coated anion exchange membranes

Ionomr Innovations Inc. has released a catalyst coated membrane (CCM) based on its Aemion anion exchange membranes (AEMs) to develop low-cost green H2 systems. This marks a new era in green H2 production with CCMs that contain no iridium and are void of the toxic perfluorinated (PFSA) substances that conventional materials contain.

Green H2 production by electrolysis typically relies on rare and expensive noble metal components such as iridium, which are the preferred catalysts for producing H2 through electrolysis at scale using intermittent renewables. The total production capacity of iridium is approximately 7.5 tpy, which represents only 30 GW/yr potential electrolyzer production at today’s catalyst loading and is one of the major limitations in expanding green H2 production to meet ambitious global targets.

Precious metal-free systems are available using alkaline technology with porous separators; however, these continue to struggle with ramping up and down to match electricity profiles from renewable power due to separator challenges in preventing the H2 and oxygen from mixing. For flexible membrane-based technologies, PFSAs are the conventional polymer electrolyte membrane material. PFSAs are known to be harmful, bioaccumulative environmental toxins that cause dire health effects.

Through significant reduction in precious metal usage, the capital expenditure (CAPEX) of the membrane electrode assembly (MEA), and therefore the stack and system, are reduced dramatically. This reduction in CAPEX along with the high efficiency provided by the CCM enable significant reductions in operating expenditure (OPEX) by reducing the cost of capital contribution to the H2 price when paired with intermittent renewables, which have a low-capacity factor. The use of these low-capacity factor electricity sources is the only way to provide the electricity prices needed to produce H2 at < $2/kilogram (kg), and the release of AEM-based CCMs marks a major step forward in competitive green H2 production.

Ionomr synthesizes membranes and polymers from a hydrocarbon base that demonstrates no bio-accumulative tendencies and are non-toxic to the environment via production and disposal. Ionomr’s materials are recyclable and enable system circularity by environmentally friendly catalyst recovery, making them the ideal replacements for standard membrane and polymer products containing PFAS.

For more information, visit https://ionomr.com/solutions/aemion/

ITM Power and Sumitomo complete installation of demonstration electrolyzer in Japan

ITM Power’s collaboration with Sumitomo Corp. has reached a milestone: the delivery and installation of a NEPTUNE electrolyzer at Tokyo Gas Co. Ltd.’s Yokohama Techno Station. This unit marks the first deployment of a MW-class proton exchange membrane (PEM) electrolyzer made overseas and imported into Japan.

Manufactured by ITM in the UK and shipped to Japan, the electrolyzer is now installed. After commissioning, the H2 produced will be utilized in Tokyo Gas’s production of eMethane. This is an important milestone on Japan's journey to carbon neutrality by 2050.

For more information, visit https://itm-power.com/how-it-works/pem

Ecolectro achieves breakthrough production and efficiency milestones

Founded on pioneering research conducted at Cornell University, Ecolectro has developed proprietary AEM electrolyzers designed to significantly reduce the cost of green H2 production. Ecolectro, an emerging green H2 generation company, has hit best-in-class performance milestones using its AEM chemistry in membrane-based electrolyzers. Ecolectro has achieved peak production rates of > 4 A/cm2 at current densities of < 2.1 V and has achieved cell efficiencies of > 74% with high H2 production rates.

The company's current density sets a benchmark within the AEM industry and matches the best cell efficiencies of most PEM electrolysis technologies. With this technical breakthrough, Ecolectro-powered electrolyzers can provide green H2 at significantly lower costs. Ultimately, the company anticipates achieving further improvements with a target efficiency of an industry-leading 80% or more.

The production rate and efficiency achievements have been demonstrated using Ecolectro's proprietary hydrocarbon-based chemistry, which avoids the use of any perfluoro-alkyl substances (PFAs), iridium-based catalysts and titanium-based components in the plates and porous transport layers. These material innovations not only lead to an 80% cost reduction compared to PEM-based stacks but have also significantly lowered Ecolectro's carbon footprint and enhanced the sustainability of operations, reflecting the company’s commitment to environmentally responsible practices.

In addition to the performance milestones, the company has successfully scaled its electrolyzers from the lab scale to the pilot scale, deploying a pilot electrolyzer at a utility company and producing green H2 onsite for further use.

For more information, visit https://ecolectro.com/green-hydrogen/

Nu:ionic H2-producing microwave reactor reaches commercial threshold

Nu:ionic Technologies has achieved a significant product development milestone with the completion of a continuous 48-hr demonstration run of its proprietary microwave catalytic reformer (MCR). This commercial scale, 100-kW electrified reactor can be used in many applications for low-carbon H2 production from various feedstocks, including biogas, natural gas or renewable ammonia. The reactor is undergoing rigorous testing and accumulating run time in the company’s Fredericton, New Brunswick Research and Innovation Center.

The next step is the installation of a fully integrated demonstration unit, which includes a H2 purification and carbon capture system, at a customer site in Western Canada. The carbon capture system produces readily transportable liquid CO2 for reuse or sequestration.

Nu:ionic’s MCR technology is well-suited for small-scale, low-carbon H2 production, ranging from 1 tpd−10 tpd, and accommodates low-cost H2 carriers such as renewable ammonia, methanol, biogas or natural gas as feedstock. Additionally, it can be used for H2 blending, clean fuel generation, pre-combustion carbon capture, chemical feedstock or energy storage. The MCR process uses approximately 30% less natural gas compared to conventional reformer methods, reducing the associated upstream emissions of natural gas exploration, production and transmission while also eliminating the need for cost-prohibitive, post-combustion carbon capture. The MCR package is also significantly more compact compared to the conventional SMR equipment footprint.

For more information, visit https://nuionic.com/teal-hydrogen/

H2 APPLICATIONS INNOVATION

Accelera fuel cells power locomotive in Austrian project HY2RAIL

Accelera by Cummins, the zero-emissions business segment of Cummins Inc., has reached a significant milestone by successfully commissioning its first fuel cell-powered locomotive for freight rail applications. Replacing typical diesel generators, Accelera fuel cells now serve as the primary power unit in the conversion project of a light on track machine (OTM) vehicle in Austria developed for the HY2RAIL project.

In partnership with the Austrian railway authority ÖBB, recognized for managing one of Europe's most advanced railway systems, the HY2RAIL project demonstrates how fuel cells can sustainably meet the power needs of heavy-duty freight locomotives.

To power the locomotive, m.ZERO, an Austrian engineering consultancy, integrated Accelera fuel cell power modules into a strong 120-kW system. This customized system meets strict rail vehicle standards, including the European standard EN 61373, which outlines testing requirements for railway applications, focusing on shock and vibration.

Furthermore, m.ZERO oversaw the integration of all balance-of-plant components and interfaces in collaboration with Accelera. The fuel cell system was then combined with a ternary battery system to create a hybrid propulsion system that includes cutting-edge power electronics, onboard H2 storage technology, a vehicle control unit and software. This integration was led by m.ZERO in partnership with project leaders Hy2RAIL.

ÖBB’s technical service arm, TrainTech, played a pivotal role in overseeing the railcar’s modernization. The transformed locomotive was previously an OBB X534-type catenary construction and maintenance railcar, reliant on a diesel-electric propulsion system. Following the installation of the new fuel cell electric system, it now runs emissions-free.

For more information, visit https://www.accelerazero.com/fuel-cells

H2 STORAGE AND TRANSPORTATION APPLICATIONS

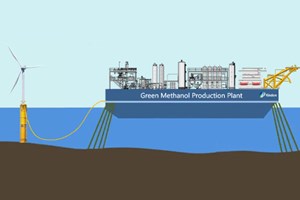

RINA awards Jiangsu approval in principle (AiP) for innovative direct air capture (DAC) green methanol offshore production platform

The inspection, certification, ship classification and engineering consultancy multinational, RINA, has awarded Kindon New Energy Technology (Jiangsu) Co. Ltd. an AiP for its green methanol offshore production platform solution. Produced entirely offshore, the methanol is derived from renewable carbon dioxide (CO2) through DAC technology and green H2 from offshore wind power water electrolysis technology.

The platform will produce 100,000 tpy of green methanol. The process synthesizes methanol from H2 and CO2 under high temperature and pressure conditions. All methanol synthesis processes are completed on the offshore platform and electrical needs are fully met by green electricity generated from offshore wind power. By using DAC technology, the CO2 is readily available; however, the system is also designed with interfaces for future access to external supplies of green or biomass-derived CO2.

HyAxiom and Doosan pass solid oxide fuel cell (SOFC) components environmental testing for maritime application

HyAxiom and Doosan Fuel Cell Co. Ltd.’s (DFCC’s) SOFC stack has passed a critical environmental test by DNV, the classification society and a recognized advisor for the maritime industry. This is the company's first SOFC cell stack to pass such a test, which is a core component of the marine SOFC under development by HyAxiom and DFCC.

Electrical equipment installed on vessels must pass extreme environmental testing under actual operating conditions, including temperature, humidity, vibration, inclination and electromagnetic interference. The next milestone will be to achieve overall SOFC certification and conduct full-scale demonstrations.

HyAxiom and DFCC signed a consortium agreement in 2022 with Shell Plc and HD Korea Shipbuilding & Marine Engineering, an intermediate holding company in the shipbuilding sector of HD Hyundai Group. The consortium aims to develop, manufacture and install a 600-kW SOFC auxiliary power unit (SOFC APU) on a Shell-chartered LNG vessel, which will undergo a year of testing in 2025 to demonstrate the technology's ability to reduce carbon emissions from maritime transport, a sector that is vital to trade and economies worldwide but is considered hard-to-abate.

Last year, the International Maritime Organization (IMO) approved an amendment to its greenhouse gas (GHG) emissions goal, which now aims to reach net-zero GHG emissions from international shipping by or around 2050, along with a commitment to ensure an uptake of alternative zero- and near-zero GHG fuels by 2030. This strategy, along with the economics of carbon and fuel reduction, sets the stage for HyAxiom's and DFCC's SOFC technology and positions the product as a highly sought after maritime mobility solution.

For more information, visit https://www.doosanfuelcell.com/en/media-center/medi-0101_view/?id=145&page=0& H2T