Articles

Highlighting the benefits of hybrid power solutions

Digital Technologies

M. HUEFFER, M. GLOTZBACH, Siemens Energy

Today’s energy systems are a far more heterogenous mix of technologies than at any time previously. Renewables like wind and solar are largely present, but their position remains alongside thermal generation technologies like gas turbines and reciprocating engines. This trend goes beyond generation: new types of large loads—such as data centers, heat pumps, battery storage and electrolyzers used to produce hydrogen (H2)—are also becoming more prevalent.

This period of dynamic change shows no signs of abating. As more assets come online, the energy landscape shares little resemblance to that of even a few years ago. Previously, the energy landscape consisted of individual, central conventional power plants near large load centers that reliably supplied electricity and were connected to each other via power grids. Now, the energy generation system is a far more distributed and decentralized portfolio. Generally, this is a positive change as the carbon intensity of the energy system steadily improves; however, for owners and operators, managing a mixed portfolio of energy assets can be challenging.

The requirements for future power generation plants—regardless of whether they are conventional or renewable plants—have changed. Today, grid codes require additional capabilities (e.g., flexibility, island capability, grid stability functions). So-called hybrid power solutions that contain at least two kinds of asset classes, such as electrolyzers for H2 production, gas turbines, renewables and battery storage, are not a new idea.

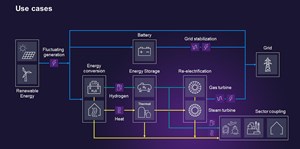

Several different theoretical building blocks or technologies are available, but the core of this concept is the integration of multiple technologies to transform, use, store and distribute energy for decarbonization. The key to integrating these assets is to combine them in an effective way to ensure they have more added value than the sum of the parts. Fortunately, the tools for getting the best out of the energy collective have evolved (FIG. 1).

Pioneering hybrid power solutions. The authors’ company has been developing hybrid power solutions and offers a system that combines mechanical integration and a smart control system. It allows these diverse assets to interact both with each other and with various user needs. With effective control, a combination of technologies becomes far more valuable than any single element or even a suite of technologies that operate independently (FIG. 2).

An example of a hybrid project is underway in the UK where the authors’ company has signed a contract for a front-end engineering and design (FEED) study for SSE and Equinor. This project is focused on H2 production, its subsequent storage and the re-electrification of the Aldbrough gas storage facility. Located on the East Yorkshire coast of the UK in the Humber region, the project consists of a 35-megawatt (MW) electrolysis system, a converted salt cavern and a 50-MW open-cycle gas turbine (OCGT).

The authors’ company is working with Black & Veatch on the FEED study, which began in June 2023 with a final investment decision (FID) to be taken in 2025 contingent on the UK government’s support across this value chain.

SSE and Equinor have an existing series of nine gas caverns at the site and plan to convert one to store H2 with an electrolyzer plant built adjacent. If executed, the proposal will see the H2 converted back into electricity using a gas turbine. The authors’ company will produce the H2 using its proton exchange membrane (PEM) electrolyzer and then interface with SSE for the underground storage elements to be followed with the re-electrification in one OCGTa.

Hybrids are not pure energy-producing or H2-producing assets, but rather a smart asset base to use with as many technologies as needed. The hybrid power solution is engineered as an optimized approach and efficiently controlled for the best outcome while ensuring that the whole plant, including the grid connection, operates efficiently and provides multiple advantages. Better dispatchability, higher availability and more power accessible for the market are all possible. It is worth recognizing that there is more than one optimal outcome.

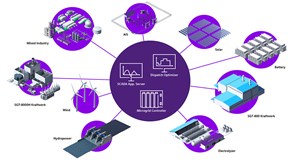

The hybrid control systemb is based on SPPA-T3000 technology to flexibly manage all the unique arrangements that comprise hybrid power solutions (FIG. 3). As a single operating system, it enables the operator to monitor and control all various plant processes. One of the modules and the dispatch optimizer allow for the economic optimization of the system based on sophisticated forecasting of weather and system demands. The calculation is done every 15 min when the various setpoints for each of the hybrid elements are sent to the controller to manage the assets in real time. The smart gas turbine control system can forecast problems in the grid, prepare the grid to start up and step in to support the grid in a timely way to avoid any potential issues (e.g., blackouts).

Greater than the sum of the parts. In addition to the cost and value elements, other plant operator options include predictive modeling for various failure modes and controlling the equipment to always operate at maximum efficiency. Under these conditions, electrolyzers can be paired with a heat pump to increase efficiency. The heat pump can use the excess heat of the electrolyzer to produce higher temperature heat (e.g., in Europe for district heating). This allows the efficiency of the electrolyzer to be significantly improved (FIG. 4).

PEM electrolysis can also help to stabilize the grid, as the very fast ramp-up rates can be used to limit negative influences from renewable generation. H2 production can be harmonized to absorb power from the grid or free up energy, if needed, by reducing H2 production and related electricity demand, and therefore, meet the requirements from the supply and demand sides.

In addition, optimizing the running system can, for example, minimize the ramp-up and rundown rates of the gas turbine to reduce wear, or reduce the number of charge and discharge cycles of a battery to extend its life. By utilizing weather forecasting, it is possible to leave a battery system discharged because there is sufficient renewable capacity or to avoid producing H2 when energy is expensive. For owners and operators of a range of assets, installing a hybrid power solution enables them to optimize for grid stability, maximize returns or extend lifespan. Furthermore, these parameters can be changed during the lifetime of the system. If the grid code regulations are modified, the system can also change to reflect new conditions.

An example of the added value the hybrid power solution brings comes from the dispatchability of energy to meet system demand. Today, the renewables contribution to the energy mix typically has priority dispatch; however, to make renewable capacity generally dispatchable at scale would require many MW of additional storage capacity. This would be a costly endeavour. An effective hybrid power solution allows the building of a dispatchable system by combining the technological capabilities of, for example, a gas turbine with renewables, and by reducing the electrolyzer demand to free up additional capacity, as needed. This is one way the grid can be stabilized.

The most critical element when bringing an additional energy asset such as a wind park or photovoltaic (PV) plant onto the grid is to not influence the grid in a negative way to the extent that a grid connection request is denied. With the integrated solution approach and an energy system design where the client’s needs are considered in detail, this includes all the different boundary conditions, such as the grid connection requirements. This in-depth knowledge of how the grid operates and how various assets (both generation and load) can react to support grid stabilization is key to the successful integration of energy assets and the effective deployment of individual parts within the full hybrid power system. Depending on the technology, it is not only possible to integrate renewables so that the grid still works, but also so that operators can see the system benefits from all the different technologies.

Built on portfolio expertise. For the energy management of hybrid power solutions to function effectively, it must be coupled with a profound understanding of the various equipment components and a deep knowledge of all related systems. This includes not only the electrolyzer, but also the electrical integration and complete H2 system that lies behind it. This knowledge should include how the systems work, as well as operational functions like lifespan degradation and the best way to use the equipment to put the energy system puzzle together.

The author’s company can offer this as part of its broad in-house portfolio that covers all the various technologies like wind turbines, gas turbines, PV, electrolyzers, battery energy storage systems and grid technologies, as well as elements such as grid studies, test beds and energy system design. Major advantages of building these hybrid power solutions around existing infrastructure is the significant cost savings and reduced lifecycle CO2 emissions, thereby promoting synergies between existing and new assets. These assets can also potentially be upgraded to be fully H2-ready turbines to take advantage of future power market developments.

The hybrid system resolves what may be a problem for the grid (e.g., adding significant new loads), and instead creates a grid stabilization asset. For developers and utilities, this equates to a reduction of project risk as the development is far less likely to be refused a grid connection under these circumstances. Instead, a hybrid plant can bring added value to any new development.

NOTES

a Siemens Energy’s SGT-800 open-cycle gas turbine

b Siemens Energy’s Omnivise Hybrid Control system

About the authors

MARIO HÜFFER is the Head of Hybrid Power Plants Solution Development at Siemens Energy.

MARKO GLOTZBACH is the Technical Sales Manager, Hybrid Solutions at Siemens Energy.