Articles

Methanol as a H2 and energy carrier

Executive Viewpoint

K. R. Radtke, Global Head of Business Development and Strategy, thyssenkrupp, Dortmund, Germany

Sustainability has reached all market segments and has already begun transforming the energy supply and demand pattern as we knew it from the past century. The agenda of the past is no longer written by oil and gas-rich regions, which were meant to supply all countries that had insufficient or no oil and gas resources with an almost unlimited supply via pipeline and/or ocean carriers, irrespective of any carbon footprint concerns.

Today, the global energy supply and demand balance is driven by entirely different parameters that are strongly influenced by the availability of sustainable, clean energy carriers, and include renewable power to generate green hydrogen (H2), biomass to convert to bio-syngas derived products, carbon dioxide (CO2) sources to recycle carbon by way of carbon capture and utilization (CCU) or carbon capture and storage (CCS) options in regions, where this is geologically and politically feasible, and other rationale that are resetting regional powers and priorities in the global energy household. Regions rich in coal reserves are often short of renewable power or alternative sustainable energy carriers. Regions with a high energy demand are often confronted with limited domestic energy sources and depend on imports.

At this stage, it is too early to project which of the known and future energy carriers will replace the dominance of coal, oil and gas in the long term. However, it is certain that we will continue with an energy mix with multiple pathways, and it is likely that we will see several different solutions that will coexist—e.g., oil, coal, natural gas, nuclear and renewables have been co-existing over the last several decades.

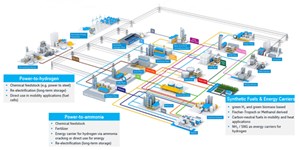

One of the primary tasks is to reduce CO2 emissions in energy conversion and in the chemical industry sectors. It is well understood that renewable power can be converted to green H2 by electrolysis, and the green H2 market is already unfolding globally in a gigawatt scale, targeting the massive H2 offtake demand that is projected to continuously grow economies seeking a carbon-free future (FIG. 1). Green H2 is an excellent energy carrier to counter climate change. However, it can be produced most cost-effectively in regions with an abundant and inexpensive supply of renewable energy, competitive incentive schemes, subsidies and other framework conditions, and political stability.

To match regional supply and demand inequalities, it is important to find the most efficient solution to transport energy from one region to another—i.e., H2 carriers, which are chemical molecules containing H2. Today, we observe that the market has made the choice for ammonia and methanol as the two most prominent H2 carriers (FIG. 2). The main difference between these two is that ammonia is H2 combined with nitrogen and remains a carbon-free molecule, while methanol is a hydrocarbon and requires a carbon source, a H2 source and some oxygen.

Ammonia has a higher energy density than pure H2 and is easier to transport and handle, especially over long distances. Once imported at a destination, ammonia can either be directly combusted in a power plant, generating power from a carbon-free feedstock, or it can be utilized as feedstock to an ammonia cracker, which breaks ammonia back into nitrogen and H2 for H2 offtakers. Of course, ammonia will continue to be used in the chemical and fertilizer industries.

For a successful turnaround in energy and industrial policies, new collaborations and openness on the part of companies are required. Green energy transformation goes along with the combination of industry sectors that had never worked together: the renewable power provider is now dealing with shipping companies and the chemical industry, while chemical producers are now confronted with electrons and electrolysis plants, and new joint forces are required to bring the energy conversion to a full success.

Another important element is the optimization of the grand picture, from power generation to final utilization of the product. Industry must find the optimum between the intermittency of power supply from renewable sources—wind, solar and hydropower have very different supply patterns—in conjunction with H2 manufacturing, ammonia or methanol production, and long-distance transportation and further reconversion. An optimized solution will reduce capital and operational expenditures of the entire value chain and is therefore key to accelerate the acceptance of new energy supply mechanisms globally.

It is quite common to talk about clean H2 solutions (blue or green H2). However, it is often forgotten that we must look at the carbon element, as well. Nearly all our surroundings consist of hydrocarbons, and finding a H2 solution is not sufficient. We must identify the cleanest possible sources of carbon. Next to the biogenic routes—where we can make use of green carbon via biomass gasification or biogas sourcing—we must also look at blue solutions in which carbon is sequestered to avoid direct emissions to the atmosphere. In this case, CCS and CCU will allow either the long-term storage and avoidance of related CO2 emissions into the atmosphere, or the recycling of carbon to substitute the same amount of carbon that would otherwise be sourced from additional fossil feedstocks.

Biomass can also be used to make green methanol via gasification (FIG. 3). This can be combined with water electrolysis to adjust the H2-to-carbon ratio at the beginning of methanol synthesis.

Our organization is seeing massive demand and a very high degree of acceptance of all solutions/technologies that help reduce carbon footprint and support climate targets. Technologies for sustainable solutions are available and need little to no adaptation to green and blue solutions. Clean energy solutions have another thing in common with their conventional technology forefathers, the economy of scale. The larger a unit can be built, the higher the capacity can be, thus lowering product generation costs. Combined with smart subsidy programs, this gap can be further closed and will accelerate a global energy transition to the advantage of the entire world. H2T

NOTE

a thyssenkrupp’s PRENFLO gasification process

About the author

KARSTEN R. RADTKE earned an MS degree in mechanical engineering and energy and environmental technologies from the Ruhr University in Bochum/Germany. He has worked for more than 30 yr with thyssenkrupp Uhde. He began his career in process engineering in the field of oil and coal gasification. He worked as an operating engineer in syngas generation for oxo chemicals at Hoechst AG, was assigned to the Molten Metal Technology in Massachusetts, and later headed the Gas Technologies Division within Uhde for 8 yr. In 2013, Radtke became President and CEO of Uhde Corporation of America. After his return to Germany, he now heads global business development, sales and strategy for thyssenkrupp Uhde.