Articles

Process optimization begins with integration

Process/Project Optimization

M. RENDON and P. DICKERSON, Emerson, Houston, Texas

Pipeline operations have a long tradition of stability. Like any industry with such a storied past, new solutions occasionally arrive on the market and offer some variation; however, successful operations generally rely on decades of standard operating procedures and expertise, with similar solutions utilized by most pipeline operators and businesses. As a result, companies are operating profitably the same way they have for decades. However, global pressure to transition to renewable, sustainable and lower emissions resources is rapidly changing this paradigm. Nowhere is this more obvious than in a globally increased focus on hydrogen (H2).

Today, companies are discussing and evaluating several ways to bring H2 into pipeline networks. Some are considering blends of natural gas enriched with H2 to reduce the carbon dioxide (CO2) emissions emitted during combustion of their products. Others are evaluating the potential for transporting H2 via a carrier such as ammonia—particularly in the ship transportation sector—while some companies are evaluating new pipelines to carry pure H2 streams across countries and continents.

H2 is approximately four times less energy dense in a gaseous phase than much of the gas today’s pipelines are already transporting. Because moving H2 in a liquid phase must be done at a very low fluid temperature, it does not lend itself to transportation by pipe. Moreover, the unique properties of H2 will require new technologies and equipment that are likely to change the overall cost structure of pipeline operations. To offset these changes for efficient and profitable operation in this new energy economy, companies must streamline operations.

Current operations—those based on decades of knowledge and industry expertise—are typically profitable but can always be improved. Future operations must be even more efficient to compete as more stringent regulations, market shifts and new players in the global marketplace increase complexity and competition.

Data silos increase complexity. The first step in capturing this operational efficiency is breaking down silos between operations and commercial business areas. Today’s most successful companies are accomplishing this strategy by selecting technologies designed around a boundless automation vision, where data moves seamlessly across every level of the organization. The earliest stages of this transition start with selecting automation technologies designed to integrate seamlessly out of the box, empowering teams to quickly and intuitively engineer inefficiencies out of the system (FIG. 1).

The operational side of a pipeline business has a few core competencies that are essential to moving any product across its network. At the heart of every decision made in operations is the goal to maintain the safe operation of the pipeline. Typically, the operations team is instructed regarding how much product they need to move, from where and to where, and they perform an analysis to see if that movement is possible. Managing profit and loss are secondary to avoiding/preventing leaks or accidents.

Operators monitor hydraulic parameters such as flow, temperature and energy density, typically using hydraulic simulation software. Using predictive or nomination data across a deterministic model, the operations team identifies how the pipeline will behave in the next nomination period, and they then accept or reject nominations based on those details. If the team does not have operational certainty across the nomination period, the operation must be adjusted.

In contrast to operations, the commercial side of a pipeline company is responsible for buying, selling and transporting gas through managed nominations, as well as showing profit when operations are complete and prioritizing customer needs and contractual obligations. For example, if a customer requests nominations based on contracted energy supply, but those nominations are unachievable, it is up to the commercial personnel to work with the customer to find alternative solutions to avoid fines and penalties. To facilitate the commercial processes, a pipeline business uses specialized digital solutions—typically transportation and transaction management software—to perform billing, contract management, measurement, balancing, invoice management and reporting.

In a traditional configuration, where the operational and transaction management software solutions are not connected—or are only loosely connected—the two groups work mostly in isolation. Operational personnel rarely talk to commercial personnel and vice versa, and that lack of communication often creates inefficiencies that lead to lost revenue or increased costs. If operations does not know what nominations are coming, they cannot effectively plan to run their equipment at maximum output, safety and efficiency.

Conversely, if the commercial side of the business does not have visibility into operation’s capacity to deliver, they might make business agreements they cannot fulfill. Moreover, even if the communication between the groups is good enough to avoid problems with delivery, disconnected systems significantly delay the process of invoicing, documenting and reporting for completed transactions, leading to receipt of revenue delays and lower customer satisfaction.

Seamlessly integrated technology provides transparency. When operations and commercial processes are disconnected, day-to-day procedures on both sides become far more complex. Sometimes the operations team will be able to meet requests for nominations, and other times it will not. Moreover, in systems where data is isolated, information is subject to duplication, inconsistency and errors from manual data entry.

As markets rapidly change, companies facing these challenges will lack the optimized processes they need to quickly respond to those changes. For example, if a governmental or organizational regulator needs to know the available capacity daily, disconnected systems or poorly connected systems will make it difficult to demonstrate capacity correctly and on time, which could result in financial and reputational penalties.

Ultimately, the best solution is seamlessly integrated software solutions to manage pipeline operations and commercial transactions. As companies embrace the new H2 technologies that will help them capture a growing market, they must drive operational efficiencies higher if they are to remain profitable. A holistic, seamlessly integrated ecosystem of operations and transaction management software will help them drive that operational excellence.

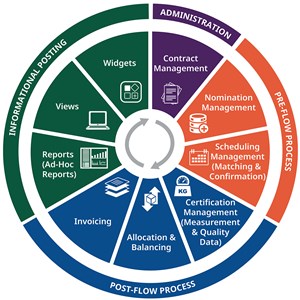

The most advanced energy operations and transaction management software solutions are designed to connect out of the box, without requiring complex custom configuration. These software packages unite pipeline transportation and transaction management software with pipeline management and engineering software solutions via a cohesive interface. Data moves freely among all applications, and users can navigate among them with a single click (FIG. 2).

One of the key benefits of fully integrated operations and transaction management software is improved user support. New users can be trained on a single interface but still have visibility across the entire value chain. Moreover, whether they work in operations or in the commercial side of the business, users gain a shared knowledge and terminology for the software, making it easier to collaborate across business areas.

Such seamless visibility and usability are difficult to achieve with a complex web of disparate solutions connected via custom configuration. In theory, any two systems can be connected, but the practicality of building that interface and keeping the systems connected is often extremely complex. Solutions with out-of-the-box integration mitigate these challenges.

Additionally, the impact of cybersecurity considerations cannot be overstated. Cybersecurity holds significant implications for pipeline operators because their infrastructure is critical to the functioning of various industries and the broader economy. Ensuring secure connectivity and ongoing protection on these integrated systems is crucial to safeguarding sensitive data and protecting against cyber threats. Moreover, as systems change due to updates, cybersecurity enhancements and hardware replacements, among others, maintaining connectivity becomes even more critical.

With robust cybersecurity measures in place, secure connectivity can be maintained across all the company’s essential applications, mitigating the risk of breaches or unauthorized access. In the event a connectivity or other problem arises, the impacted users will have a single point-of-contact for issue resolution, streamlining troubleshooting efforts and minimizing potential cybersecurity vulnerabilities.

Support for scalability. Another key advantage of pipeline operations and transaction management software platforms that are integrated by design is the enhanced ability to scale operations successfully—a differentiator that will be critical for companies experimenting with H2 pilot programs. New operations might have neither the need nor the resources for full-scale pipeline engineering, operations, forecasting and commercial tools in their earliest stages, but they could need some or all of this functionality in the future.

For example, a company investigating if it can meet a new market demand might need to start with a pilot, or even a simulated test, to determine if the enterprise would be profitable. Such an organization might start with a load forecasting tool coupled with a pipeline engineering tool to determine if the project is economically viable. Such tests and pilots are likely to become increasingly common as companies investigate new energy sources like H2. These companies must evaluate pressure, flowrates, equipment and materials risks, and more, along the right-of-way.

Beginning these investigations with tools that are integrated by design will make the scale-up process much faster for successful ventures. When the company decides to go ahead with the project, the engineering is already completed, and every other tool they need to use can be integrated in a matter of minutes. Such companies are faster and more agile, bringing projects online quicker and then generating more revenue in the earliest stages of operation (FIG. 3).

A foundation for a more profitable future. The impacts the new energy economy will have on pipeline companies cannot be predicted with certainty. As markets, regulations, materials and technologies change, most companies must make rapid shifts to meet new demands. Navigating those changes, while also struggling with siloed data, will create complexity that will likely turn into speedbumps or roadblocks in the value chain as companies attempt to bring new operations online.

Therefore, a strategic shift to an integrated-by-design pipeline operations and transaction management platform is one of the best investments a company can make. A built-for-purpose and intuitive solution will not only increase the profitability of current operations, but it will also help position companies to take advantage of opportunities arriving in the coming years and decades. H2T

About the authors

MARTHA RENDON is Senior Product Manager for Emerson’s Gas Management Solutions portfolio. She has more than 20 yr of experience, 15 of which have been in the energy sector with a focus on globally deployed software projects, systems design and product roadmap management. Rendon is skilled in delivering complex solutions and consistently demonstrates a strong customer focus, keeping projects under-budget and ahead of schedule. She is certified as a Project Management Professional (PMP) and for business design thinking. Rendon holds a BS degree in engineering computer science, and an MS degree in organizational control business administration and management, both from EAFIT University in Medellín, Colombia.

PAUL DICKERSON is the Global Product Lead for pipeline simulation products at Emerson. He has been involved in pipeline simulation for more than 25 yr, mostly in the energy, water and wastewater industries. His focus is on globally deployed software solutions to manage the complex operational problems of the pipeline industry, working closely with customers to deliver best-in-class results. He holds an undergraduate degree in computer systems engineering from the University of Sunderland, England, a Global MBA from Durham University, and is a Chartered Engineer as a Member of the Institution of Engineering and Technology (MIET).