Articles

H2Tech: Tech Spotlight

TYLER CAMPBELL, Managing Editor

H2 PRODUCTION

Shanghai Electric lowers costs of H2 with Z-series alkaline electrolyzer

Shanghai Electric has made another significant stride in lowering the overall costs of green H2 with its latest Z-series alkaline electrolyzer technology, an energy-saving innovation that breaks through the bottleneck of the renewable energy sector to make emissions-free H2 production more economically sustainable.

Green H2 is emerging as a crucial solution in the global quest for renewable energy and decarbonization, but the overall economic feasibility of its production, storage, refueling and usage is a major development constraint. Shanghai Bright-H Technology Co. Ltd., a subsidiary of Shanghai Electric, has been focusing on industry pain points and technological challenges, fully addressing the key links in the H2 energy development chain.

Through exploring alkaline water electrolysis and proton exchange membrane (PEM) water electrolysis, the Bright-H Technology is dedicated to providing integrated production, storage, refueling and usage system solutions for the company’s customers, achieving breakthroughs in green chemistry, metallurgy, transportation and energy storage.

For more information, visit: https://www.shanghai-electric.com/group_en/cydt/cphfw/

Gold H2 introduces H2-producing microbial technology

Gold H2, a Houston, Texas-based clean H2-producing company, has announced that its Black 2 Gold Technology (B2G), the company’s proprietary industrial biotech process that upgrades crude oil into biologically produced Gold H2®, is available to select oil and gas owners and operators for pilot demonstrations. This is accompanied by the signing of a significant memorandum of understanding (MoU) in the U.S. with a major oil and gas company, marking the beginning of a series of pilots with large oil majors over the course of the next 12 months.

This pilot will commercially demonstrate Gold H2’s first-of-its-kind Gold H2-producing biotechnology and aims to produce cheaper, cleaner H2 than ever before ($0.80/kg). The technology will help produce new clean energy sources and allow oil and gas companies to transform uneconomical, non-productive oil wells into mass H2-producing assets. This business model will reshape the traditional oil and gas industry landscape by further accelerating the clean energy transition and creating new economic opportunities in areas that were previously dismissed as unviable.

Under the right conditions, depleted oil reservoirs can be transformed into subsurface H2 biorefineries. With current iterations of its solution, Gold H2 targets reservoirs that are currently, or have the capacity to be, waterflooded with temperatures between 130°F and 180°F and total dissolved solids concentration of less than 100,000 ppm.

Supplementing a water flood injection system, Gold H2 deploys the Mobile Microbe Manufacturer (M3), an onsite fermentation unit, to inject its microbes along with additional nutrients to begin the production process. Each M3 can convert up to 120 oil wells, and each well is expected to produce up to 2.5 tpd of H2. Gold H2 also takes several steps for risk mitigation, including utilizing targeted biochemistry, installing a minimal equipment footprint and using non-GMO microbes. The Gold H2 solution is optimized to mitigate concerns of corrosion or biofouling.

For more information, visit: https://www.goldhydrogen.com/

H2 EQUIPMENT

Intelligent Energy launches IE-FLIGHT H2 fuel cell system products

Intelligent Energy (IE) unveils its IE-FLIGHT family of aviation fuel cell products for sub-regional and regional aircraft, marking a significant development milestone and step towards realizing sustainable aviation.

IE-FLIGHT fuel cell system products offer the following benefits:

- Market-leading power densities

- Unique high-temperature heat rejection architecture allows the fuel cell system to operate at high temperatures, enabling a smaller heat exchanger for less weight and aircraft drag

- Class-leading transient response times

- True zero-emissions flight.

The IE-FLIGHT F300 can be either installed on new Part-23 aircraft designs or retrofitted onto existing Part-23 aircraft. The IE-FLIGHT architecture is scalable for multi-MW fuel cell installations, making it suitable for Part-25 aircraft, as well.

The aviation industry’s shift towards zero-emissions solutions is being driven by the need to reduce greenhouse gas (GHG) emissions. The aviation industry contributes 2%−3% of global emissions; this is projected to rise to 8%−15% by 2050, based on air transport passenger traffic growth forecasts.

Intelligent Energy’s IE-FLIGHT products represent a significant advancement in the aviation industry’s journey towards zero-emissions flights and offer a number of operational and environmental benefits, including:

- The IE-FLIGHT fuel cell uses a patented evaporative cooling technology that redefines efficient thermal performance. This technology enables the operation of the fuel cell system at high temperatures, allowing a much smaller heat exchanger to be used, reducing weight, drag and enhancing overall aircraft performance, particularly at higher speeds.

- Intelligent Energy’s fuel cell system features significantly fewer mechanical moving parts compared to traditional aircraft gas turbine or piston engines. With advanced fuel cell performance monitoring methods, the IE-FLIGHT fuel cell system’s health can be accurately monitored to give operators confidence in planning service intervals.

- Compared to typical PEM fuel cell systems, the IE-FLIGHT system has a simplified balance of plant (BoP) with fewer components. This increases power density and reliability, and reduces cost at volume production.

While sustainable aviation fuel (SAF) is competitive with traditional kerosene, it is still not truly zero-emissions and is costly to produce. H2 is an appealing alternative because it produces zero emissions within fuel cells, can be produced locally and refueling times are comparable to those associated with traditional aviation fuels.

Alternative fuel cell products have been created by adapting automotive fuel cell systems for use within aviation. Intelligent Energy has taken a fundamental approach to developing a core fuel cell stack specifically for use within aviation, making IE-FLIGHT fuel cell products fit for purpose within future aircraft certification programs.

For more information, visit: https://www.intelligent-energy.com/our-products/

GKN Aerospace launches H2FlyGHT, pioneering £44-MM project for 2-MW cryogenic H2-electric propulsion

GKN Aerospace has launched H2FlyGHT, a £44-MM project. This collaborative initiative will develop a 2-megawatt (MW) cryogenic H2-electric propulsion system, setting new standards for the future generation of larger sustainable aircraft. Building on the successes of the H2GEAR project, H2FlyGHT introduces thermal management solutions to enhance efficiency and performance.

H2FlyGHT is designed to streamline the path to flight testing and certification, meeting customer needs and industry standards. The project will demonstrate an integrated propulsion system at the 2-MW scale, including fuel cell power generation, cryogenic power distribution and advanced cryogenic drive systems. GKN Aerospace is collaborating with industry and academic partners to achieve the ambitious goals of H2FlyGHT:

- Parker Meggitt: Collaborating on thermal management and BoP for the fuel cell system, ensuring comprehensive system integration and performance.

- University of Manchester: Focusing on hyperconducting motor coil design, pushing the boundaries of motor technology.

- University of Nottingham: Supporting full motor design and scale-up and cryogenic inverter technology development, essential for developing high-power, efficient propulsion systems.

For more information, visit: https://www.gknaerospace.com/sustainability/our-technology/

NREL model fast-tracks H2 supply chain infrastructure deployment

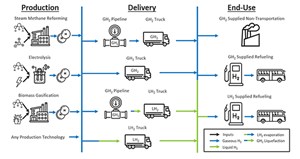

The use of clean H2 and fuel cells for transportation applications—particularly for medium- and heavy-duty vehicles—is a key part of a portfolio of solutions to decarbonize U.S. transportation. Realizing the potential of clean H2 as a transportation fuel will require successful widespread deployment of H2 fueling infrastructure.

Reducing the informational and financial risks associated with infrastructure investment decisions is vital to accelerate the adoption of H2 as a transportation fuel. This can be accomplished by helping stakeholders forecast H2 demand and minimize the cost of building infrastructure.

The scenario evaluation and regionalization (SERA) model optimizes the H2 infrastructure buildout necessary to meet the growing needs of an emerging, dynamic market at a geographic and temporal level. SERA is a flexible optimization tool that allows the user to define demand, available supply locations, technologies and distribution pathways, input prices, and cost and performance parameters, which the model uses to optimize infrastructure buildout, most commonly by minimizing costs. This model is part of a comprehensive portfolio of strategic analysis activities to assess the needs, scenarios and challenges associated with the rollout of H2 applications.

SERA has been used to design H2 supply chain infrastructure in support of both transportation and non-transportation applications, such as quantifying the cost of adopting alternative vehicles and quantifying the number and type of H2 production technologies needed to support the growing H2 market. As such, the model can be configured to address custom scenarios and assess investment and market growth dynamics on regional and national scales over time.

One such example is the model’s role in a project to plan the implementation of H2 systems in California. At the University of California, Davis leveraged SERA to model potential electrolytic H2 systems through 2050 across supply and demand sectors and achieved significant spatial detail that provided stakeholders with strategic insights.

For more information, visit: https://www.nrel.gov/hydrogen/sera-model.html

Trelleborg launches range of proven H2Pro solutions for H2

Trelleborg Sealing Solutions has launched the full H2Pro range of more than 20 sealing compounds proven to provide reliable solutions for every application of the H2 value chain. Designed to accelerate innovation for sustainable technology, the H2Pro range has solutions for the challenges of H2 production, transport and storage, and end use. Proven to withstand challenging application environments, the materials are suitable for high pressures and low temperatures, and resist permeation, making them better able to withstand rapid gas decompression (RGD) while also demonstrating excellent wear and extrusion properties.

Trelleborg has developed proprietary test standards for H2 permeation, endurance validation and H2 compatibility, including the ability to withstand RGD. Occurring when H2 permeates into a seal under pressure, RGD can cause seals to blister and crack when pressure is rapidly relieved.

The extended H2Pro range meets the diverse requirements of real-world H2 applications with elastomers including ethylene propylene diene monomers (EPDM), fluoroelastomers (FKM), silicones and Zurcon polyurethanes (PU). For other H2 sealing solutions, there are plastics and metals including Turcon polytetrafluoroethylene (PTFE), 316L stainless steel and a range of Zurcon engineered plastics in ultra-high-molecular-weight polyethylene (UHMWPE), polychlorotrifluoroethylene (PCTFE) and polyether ether ketone (PEEK).

For more information, visit: https://www.trelleborg.com/en/seals

H2 APPLICATIONS INNOVATION

Rolls-Royce and TCS collaborate on H2 research program

Tata Consultancy Services (TCS), a global leader in IT services, consulting and business solutions, has expanded its partnership with Rolls-Royce, a British multinational specializing in civil aerospace, defense aerospace, services and power systems, to advance its sustainable initiatives. This collaboration involves research into H2 fuel system technologies that will continue to prove H2 could be a zero-carbon aviation fuel of the future.

This partnership underscores TCS's commitment to driving sustainable transformation across industries, aligning with its broader mission to harness technology for positive societal impact. The International Air Transport Association (IATA) has set ambitious targets for net-zero carbon emissions by 2050, necessitating innovative sustainability solutions.

TCS will leverage its deep domain knowledge of the aircraft manufacturing industry and support the engineering activities of Rolls-Royce, such as system design, component design, supply chain support and program management. These services will help Rolls-Royce research H2 technology as it addresses three key challenges in the journey to enabling H2 for use in aviation: fuel combustion, fuel delivery and fuel systems integration with an engine. All elements must be confirmed to operate safely.

For more information, visit: https://www.rolls-royce.com/

H2 STORAGE AND TRANSPORTATION APPLICATIONS

Machine-learning advances the clean energy economy

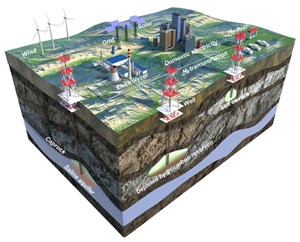

Los Alamos National Laboratory scientists are developing powerful machine-learning models—an application of artificial intelligence (AI)—to simulate underground H2 storage operations under various cushion gas scenarios. Scientists have studied the effects of cushion gasses [e.g., methane, carbon dioxide (CO2), nitrogen] on such underground H2 storage systems. However, it has never been fully understood how cushion gasses would affect the performance of underground H2 storage operations.

The Los Alamos team successfully investigated comprehensive cushion gas scenarios, providing key insights into the effects of various cushion gasses on underground H2 storage performance. Scaling the H2 economy is an important part of the world’s effort to decarbonize. Like gasoline, H2 gas must be produced and stored regionally to power clean-energy semi-trucks, generate electricity directly and provide resilience for solar power plants during the winter months.

A wide range of underground reservoirs will need to be exploited to reach this scale. Previous studies had focused on a single set of geological and operational conditions. However, to mimic real-world scenarios, the Los Alamos team’s model accounted for multiple geological conditions, the presence of water and the operational impact of several cushion gasses.

To accomplish this, the Los Alamos team used a deep neural network machine-learning model, which analyzed combinations of geological and operational parameters to mimic the variability of real-world scenarios. The team noted key findings, some of which included:

- The technical promise of underground H2 storage in porous rocks due to improved storage performance over cycles

- The advantages and disadvantages of underground H2 storage in saline aquifers and depleted hydrocarbon reservoirs

- The impact of various cushion gas scenarios on H2 recoverability, purity, water production risk and well injectivity in porous rocks.

These findings build on years of H2 storage research at Los Alamos, one of the first institutions to explore this technology from multiple angles. Los Alamos scientists have investigated the flow and transport behavior of H2 in the subsurface environment, which helps to understand the effects of cushion gas on underground H2 storage performance.

Another aspect of this ongoing research has explored potential H2 storage locations in the Intermountain West region, an effort that combines the physics of subsurface geological formations with machine-learning-powered simulations.

Yet another research branch has worked toward developing tools that can assess the reliability, risk and performance of H2 storage across a wide range of conditions. This latter work led to OPERATE-H2, the first industry-available software to integrate advanced machine-learning for optimizing H2 storage.

For more information, visit: https://science-innovation.lanl.gov/ai/

Luxfer Gas Cylinders introduces an innovation in gas containment with an advanced H2 transportation system

Luxfer Gas Cylinders, a division of Luxfer Holdings Plc., has introduced the G-Stor Hydrosphere, a collection of multiple element gas containers (MEGCs) set to revolutionize how businesses can harness the power of H2. Developed to support the safe and sustainable transportation of H2 via virtual gas pipelines, the high-capacity G-Stor® Hydrosphere range helps extend access to clean gas as the H2 economy continues to gather pace.

Offering maximum capacity and energy delivery, the G-Stor Hydrosphere range draws on Luxfer's trusted Type 4 (G-Stor Go H2) cylinder technology. Available in 20-ft and 40-ft units, the MEGCs overcome infrastructure barriers facing the H2 supply chain by effectively allowing > 1 t of H2 to be stored and transported. By maximizing payload, it provides the best price per kilogram of H2.

For more information, visit: https://www.luxfercylinders.com/products/