Articles

Blending H2 in existing natural gas pipelines: What infrastructure modifications are required?

Blending Natural Gas and H2

D. BUKŠA, Siemens Energy, Zagreb, Croatia; and R. BARREDA, Siemens Energy, Erlangen, Germany

The role of hydrogen (H2) in the global energy transition is expanding. Viable decarbonization use cases for clean H2 have emerged across various industries and applications, including power generation, steelmaking, cement production, chemicals and mobility.

According to the International Energy Agency (IEA), global production of low-emissions H2 could reach 49 million tons per year (MMtpy) by 2030.1 This strong growth has been driven primarily by announced electrolysis projects, which now amount to > 500 GW.

While continued expansion of both electrolyzers and renewable generating capacity will be key to reducing costs and achieving economies of scale, widespread H2 adoption is not possible without an extensive pipeline network to transport large volumes over long distances.

Thousands of miles of dedicated H2 pipelines are in operation worldwide today, with thousands more under development, particularly in Europe. The construction of these pipelines is costly and can be extremely complex from a regulatory standpoint, often requiring several years to obtain approval.

Blending small amounts of clean H2 into existing natural gas lines represents a potential strategy for long-distance H2 transport (particularly in the near term). This may be required for cases where a user needs a blend of natural gas and H2 (e.g., for combustion in a gas turbine). This article examines the opportunities and challenges associated with H2 injection in pipelines and discusses the various infrastructure modifications necessary to ensure safe and reliable operation.

End-use applications for H2. In the U.S. and Europe combined, there are > 4 MM mi (6.4 MM km) of natural gas transmission and distribution networks. Most of these lines have been in operation for decades and could be used to transport H2 blends of 5 vol%–15 vol% with minimal, if any, infrastructure modifications.

Currently, one of the most attractive use cases for H2 blending is in lines that supply natural gas to large thermal power plants.

Numerous power plant operators have announced H2 co-firing initiatives in recent years as part of their decarbonization initiatives. Industrial sites that use gas turbine mechanical drives [e.g., pipeline stations, liquefied natural gas (LNG) plants, refineries] are also exploring their potential via pilot projects.

Blending clean H2 with natural gas presents a viable approach to incrementally lower carbon emissions from power generation.

As an example, adding 10 vol% H2 to the natural gas fuel stream reduces the carbon dioxide (CO2) emissions of a gas turbine by approximately 2.7%. This would result in a reduction of 30,000 tons (t) of CO2 for an 850-MW combined-cycle power plant that operates for 6,000 hr/yr at 60% efficiency. Increasing the ratio to 30% H2 leads to an 11.4% reduction in CO2 emissions. The resulting CO2 avoidance for a 62-MW simple-cycle power plant that runs on this blend for 8,000 hr/yr would be around 28,000 tpy.

Another potential end-use application for clean H2 is in downstream facilities that already use H2 as a feedstock (e.g., for ammonia production, methanol synthesis, hydrocracking). Today, many refineries and chemical complexes have dedicated H2 pipeline networks in place. Virtually all the H2 transported via these pipelines is “gray,” meaning it is produced via steam methane or autothermal reforming.

Significant emissions reductions are possible by replacing gray H2 with green H2. In such cases, the green H2 can be produced at an offsite electrolysis plant and then injected into the existing H2 network.

If a H2 pipeline does not exist, it may be feasible to inject the H2 into a natural gas line supplying the facility. The H2 can then be extracted (i.e., deblended) at a specific location and compressed into onsite storage tanks. The primary challenge with this approach lies in making the process cost-effective. In addition to the initial capital expenditures (CAPEX) for the deblending equipment, the separation process requires energy input, which increases operational expenditures (OPEX).

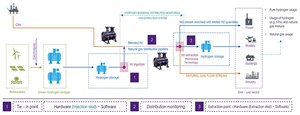

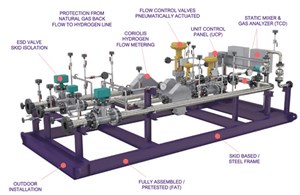

The role of H2 injection systems. In the case of H2 co-firing in gas turbines, an injection (i.e., mixing) system like the one shown in FIG. 1 is required to connect the clean H2 supply (either from an electrolysis plant or a pure H2 pipeline) to the natural gas pipeline or fuel supply. The injection skid serves critical functions, such as regulating pressure and flow to achieve the desired fuel mixing ratio, which is essential to ensure the safe and reliable operation of the gas turbine and other downstream equipment.

Homogeneous gas mixing is achieved via a static mixer in a short piping installation next to the pipeline or gas turbine. A thermal conductivity gas analyzer (TCGA) provides the final control of the mixing to maintain the safe operation of the overall gas system.

Coriolis flowmeters measure the natural gas and H2 feed flows inside the mixing skid. This information is sent to flow controllers, which operate control valves for the natural gas and H2, regulating the feed mass flowrate to meet the target blend ratio. The mixing and injection skids are equipped with pneumatically actuated control valves and emergency shutdown (ESD) valves and require an external instrument air supply, which is outside the skid’s scope.

A vent (purge) line is provided for skid depressurization, as H2, natural gas and the fuel blend may occasionally require de-inventory. Nitrogen is provided to purge the skid for safety purposes and prior to any line opening for instrument maintenance or removal of the entire skid.

Injection skids (FIG. 2) are designed and packaged to minimize onsite work and costs. They can be applied at existing pipeline or power plant facilities with minimal disruption to onsite operations.

What other infrastructure modifications are needed? Most of the H2-natural gas pipeline transport initiatives in the U.S. and around the world are exploring relatively low blend ratios, typically in the range of 5 vol%–15 vol% H2. At these levels, the impact on the total energy transport capacity of the pipeline is minimal. However, the lower molecular weight of H2 relative to natural gas (2 g/mol vs. 16 g/mol) can impact the type and design of the compression equipment. In the case of turbo-compressors, significant modifications are typically not required below 15% H2. The allowable admixture ratio is even higher for stations that use reciprocating compressors.

Similar limits exist for gas turbines used to drive compressors. Although many gas turbine models produced by major original equipment manufacturers (OEMs) today can be retrofitted to manage fuel mixtures with 30 vol%–70 vol% H2, older frames may require more substantial modifications. Burner adaptations, burner flashback supervision, enclosure gas detection systems and changes to ventilation are typical modifications required to operate on larger H2 contents.

Another potential challenge for older gas turbine frames that do not use state-of-the-art construction materials is H2-induced cracking (HIC) or H2 embrittlement. The pipelines themselves are also at risk of HIC.

HIC is a form of material degradation caused by the absorption and diffusion of H2 atoms into metallic structures, especially under pressure. When H2 is introduced, it can migrate into steel, leading to embrittlement and the initiation of microscopic cracks that propagate over time.

Industry organizations have conducted extensive research to better understand the risks associated with HIC in natural gas pipelines.2 These ongoing efforts have already demonstrated that most pipelines can be used for H2-rich blends without modification, while only overground facilities would require modification.

Looking forward. An efficient and reliable transport network is crucial to scaling the global H2 economy. While transport via truck and rail will remain an essential part of the value chain for smaller consumers, pipelines are the most economical option for moving large volumes of H2 over long distances.

The cost, complexity and lengthy development timeline associated with constructing new pipelines constrain market growth and widespread H2 uptake.

The conversion of natural gas lines to 100% H2 is being explored globally. The European Hydrogen Backbone (EHB) Initiative is the most mature framework to date, aiming to establish a robust H2 pipeline network in the EU by the 2030s.3 Some studies estimate that gradually converting from natural gas to 100% H2 is ~30% of the cost of constructing a new pipeline.4

Blending small amounts of H2 in existing natural gas infrastructure represents a viable strategy and can help facilitate adoption as dedicated H2 infrastructure slowly comes online (either through new pipeline construction or the repurposing of existing networks).

Numerous H2-natural gas blending demonstration projects have been completed over the past decade in both the U.S. and Europe. As low-emissions H2 production accelerates and demand increases to support decarbonization initiatives, more opportunities for pipeline blending projects will emerge.

In many networks, the only additional equipment needed to support blending 5 vol%–15 vol% H2 is an injection/mixing skid. The equipment for these systems is well-proven, and their installation does not present any significant technical or economic hurdles for operators. H2T

LITERATURE CITED

1 International Energy Agency (IEA), “Global H2 Review,” 2024.

2 Topolski, K., E. Reznicek, B. Erdener, et al., “Hydrogen blending into natural gas pipeline infrastructure: Review of the state of technology,” National Renewable Energy Laboratory (NREL), October 2022.

3 “European Hydrogen Backbone: Boosting EU resilience and competitiveness,” Gas Infrastructure Europe, November 20, 2024, online: https://www.ehb.eu/files/downloads/1732103116_EHB-Boosting-EU-Resilience-and-Competitiveness-20-11-VF.pdf

4 Adam, P., F. Heunemann, C. von dem Bussche, T. Thiemann and S. Engelshove, “Hydrogen infrastructure—the pillar of energy transition: The practical conversion of long-distance gas networks to H2 operation,” Siemens Energy, online: file:///C:/Users/Mike.Rhodes/Downloads/EPA-HQ-OAR-2023-0072-0054_attachment_12.pdf

About the authors

Danijel Bukša is a sales and process expert at Siemens Energy, focusing on energy storage, tank farms and terminals, LNG and fuel shift solutions. He studied mechanical engineering and naval architecture in Zagreb, Croatia. With 24 yr of experience in mechanical design and sales engineering in the oil and gas industry, his roles include R&D, business development, global sales and training in growth, energy transition, fuel shift and decarbonization.

Rodrigo Barreda is a Sales Manager for Projects, specializing in pipelines for Siemens Energy’s electrification, automation and digitalization business. He demonstrates knowledge of the significant challenges associated with pipeline projects, including international business trends, innovations, strategic direction and the effects of globalization on competitiveness, covering the areas of sales, technology and contractual complexities.