Articles

HT-PEM H2 fuel cells: The ‘Ticket to Ride’ for aviation and rotorcraft

Fuel Cell Applications

D. VASSALOTTI, Piasecki Aircraft Corp., Essington, Pennsylvania (U.S.)

If you travel by any means other than on foot, you have likely noticed the emergence of electric motors in transportation. While electric motors have traditionally dominated industrial applications and fixed mobility markets—such as escalators and elevators—over the past decade, they have made significant inroads into personal and commercial mobility. Initially powering children's scooters and skateboards, electric propulsion has rapidly expanded, gaining worldwide acceptance in automobiles, trucks, boats and recreational vehicles. This transition has been evolutionary, requiring little public persuasion, as it has been accompanied by cost incentives (electricity is significantly cheaper than gasoline) and a growing infrastructure.

However, what the public may not have noticed is that the aviation industry is undergoing its most significant technological revolution in 80 yr, particularly in rotorcraft. The shift is already in motion—electric vertical takeoff and landing (eVTOL) aircraft are poised to replace traditional helicopters, perhaps permanently. While a conventional helicopter has a development cycle of 8 yr and only large original equipment manufacturers (OEMs) can afford to introduce new variants every 15 yr–20 yr, the eVTOL sector has significantly expanded. In just under a decade, 90 new eVTOL companies have emerged worldwide, with five (Joby, Archer, Vertical, Wisk and Lilium) actively pursuing Federal Aviation Administration (FAA) certification for public operations—that is a revolution.

The enabler of this transformation is distributed electric propulsion (DEP), which utilizes multiple electric motors positioned strategically around an aircraft. Unlike a conventional rotorcraft, which requires complex gearing and heavy shafting, eVTOLs leverage DEP for lighter, quieter and more efficient flight, eliminating the need for turbine engines.

The challenge: Energy storage. What’s the catch? While DEP enables faster design cycles and improved control, it demands highly efficient energy storage. Currently, more than 95% of eVTOL aircraft rely on battery power. These aircraft are optimized for urban air mobility (UAM) missions, excelling at quick takeoffs, short cruises and efficient landings. However, expanding beyond UAM into traditional helicopter roles requires significantly more onboard energy.

Today's eVTOL aircraft max out at about 150 mi: this is sufficient for urban transport but inadequate for missions requiring prolonged hover times, such as search-and-rescue or offshore operations, use cases for which traditional helicopters are ideal. The solution to this issue is hydrogen (H2) fuel cells. High-temperature proton exchange membrane (HT-PEM) fuel cells are emerging as the optimal choice for aviation. Unlike low-temperature PEM (LT-PEM) fuel cells, which dominate commercial applications, HT-PEM fuel cells eliminate the system weight associated with liquid cooling, humidifiers and radiators, making them ideal for aerospace applications. Lowering the overall system weight is the driving factor for the development of HT-PEMs for the weight-conscious aerospace market.

Batteries and H2 fuel cells share more similarities than differences—both are solid-state devices with no moving parts. The key distinction is that batteries store a fixed amount of “fuel” (the electric charge), while fuel cells generate electricity continuously—so long as they are supplied with H2 and oxygen.

The author’s company is betting on HT-PEM fuel cell technology for its next-generation eVTOL aircraft. In a phased crawl-walk-run approach, the company is in the final build stages of the H2 co-axial electric lift (HAXEL), an HT-PEM-powered helicopter (FIG. 1).

The HAXEL program will provide critical insights for a $25-MM U.S. Air Force AFWERX contract to develop a 760-kW ground-based iron bird HT-PEM fuel cell propulsion system. This iron bird is being designed as an aviation-grade, fault-tolerant power system.

Overcoming H2’s challenges. H2 fuel cells offer several advantages but present two primary technical challenges that must be solved. The author’s company is testing H2 fuel cells at a large scale to validate power output, fuel cell endurance, fuel efficiency and transient response capability. Challenges regarding using H2 fuel cells in aviation that must be overcome include:

- Fuel cell specific power (kW/kg)

-

- Aviation fuel cells must match or exceed turbine power-to-weight ratios. Manufacturers are working to push fuel cell performance beyond 6.4 kW/kg—a crucial milestone.

- H2 fuel tanks

-

- H2 storage is a well-established industry for cars, trucks, buses and forklifts. However, aviation requires ultra-lightweight, high-capacity tanks to sustain missions lasting 3 hr–5 hr.

-

- There are three primary H2 storage methods:

-

-

- Compressed gaseous H2 (GH2)

-

-

-

- Cryogenic liquid H2 (LH2)

-

-

-

- Cryo-compressed H2 (CcH2)

-

-

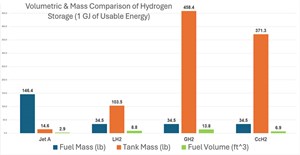

- For aviation, additional H2 storage by weight is required for 3 hr–5 hr mission profiles, which require lighter tank designs. H2 has a unique behavior between its various phases. FIG. 2 compares tank volume and weight across these storage methods. For aviation, LH2 and CcH2 are the most viable candidates and offer unique advantages, although both require further development.

The future: H2-powered eVTOLs replace helicopters. With their high energy density, sustained peak power capability and independence from discharge limitations, H2 fuel cells are the only viable pathway for eVTOL aircraft to surpass and eventually replace traditional helicopters.

The industry is moving fast—fuel cell technology is rapidly maturing. New commercial H2 fuel control systems are hitting the market and tank innovations are emerging, in part due to advancements in nanotechnology and materials science that enable durable, lightweight H2 containment. In time, LH2 and CcH2 may find distinct aviation applications, enabling the sector to take flight. H2T