Articles

Why H2 makes sense in mobility

Special Focus: H2 Equipment and Services

M. REUM, Schaeffler Technologies, Herzogenaurach, Germany

Continuing an already established trend, wind farms and solar power plants will account for an increasingly large share of the overall global energy supply. However, these facilities only generate electricity, and their output is largely dependent on the weather. This raises an increasingly important question: How can the overproduction of electricity that occurs at times be buffered as efficiently as possible? As a chemical energy carrier, hydrogen (H2) provides an answer. Generated via electrolysis, H2 offers a solution for effectively storing and transporting energy that is not required at the time of production—and, in this example, later converting it back into electricity using a fuel cell for power generation in stationary and mobility applications.

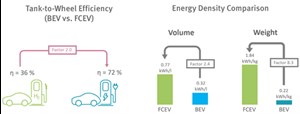

H2 fuel cells are not so much a competitor to battery-electric mobility as they are a vital complement that broadens the scope of electric vehicle applications, especially for larger, heavier trucks that travel long distances and require commensurate range. The unique properties of H2 as a chemical energy carrier, combined with its storage technology, enable it to occupy 2.4 times less space in a vehicle per kilowatt-hour (kWh) of energy than a battery of equivalent capacity. Additionally, H2 systems address one of the critical challenges in electric vehicle design: they significantly reduce powertrain weight per kWh by a factor of 8.3. These advantages outweigh the gap in tank-to-wheel efficiency, where battery electric vehicles (BEVs) lead by a factor of ~2 (FIG. 1). The efficiency debate should not overshadow the substantial benefits H2 can provide in specific applications.

Another compelling advantage of fuel cell electric vehicles (FCEVs) is their rapid refueling time. Consider this: an FCEV with a range of 400 mi. can be refueled in less than 5 min, whereas a BEV with a range of around 200 mi. often requires more than 40 min to charge. For frequent or long-distance drivers, these refueling times can significantly impact day-to-day convenience, making H2 a viable option for various transportation needs.

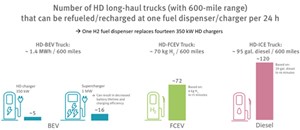

Furthermore, integrating H2 into the transportation sector has significant implications for energy infrastructure. Longer charging times for BEVs restrict the number of vehicles that can be charged within a given timeframe. A 350-kW charger can fully power just five trucks over 24 hr, while a single H2 dispenser can refuel approximately 70 trucks over the same period (FIG. 2). This stark difference illustrates how H2 can alleviate pressure on existing electric charging stations and enhance operational efficiency.

Transitioning to H2 also alters the landscape of electricity generation. According to the International Energy Agency (IEA), electromobility could drive an electricity demand of 197 terawatt hours (TWh) in a sustainable development scenario. However, by meeting part of this demand with H2, we can decouple energy generation from consumption—geographically and temporally. This flexibility allows us to optimize energy resources and mitigate stress on the grid.

These statements illustrate the advantages of H2 as a driving solution for the mobility of the future, spanning numerous fields of application. While pure battery-electric mobility is particularly well-suited for smaller vehicles in urban environments with limited daily mileage and low payloads, the dynamics shift when considering vehicles designed for long-distance travel. In such cases, FCEVs may become the preferred choice. In heavy traffic and diverse applications, fuel cell powertrains demonstrate notable versatility that even extends to railway applications.

Ultimately, embracing H2 mobility shifts our focus from merely expanding electric infrastructure to exploring innovative logistics solutions. Today’s established transport and storage capacities for compressed or liquefied gases can facilitate a seamless transition. Rather than viewing H2 as a competitor to battery technology, it is crucial to recognize it as a complementary element in the broader landscape of sustainable transportation. By investing in H2 solutions, we can build a more resilient, efficient and multifaceted energy future.

What’s holding us back. H2 mobility makes no sense without green H2, which is defined as H2 produced from renewables by means of water electrolysis. As mentioned above, it is assumed that future overproduction of renewable energy will reach a level that allows it to be used for H2 production in transport applications. However, this also implies that electrolyzer technology will serve as the key enabler of H2 use. Unlike fuel cells, electrolyzers do not have a decades-long history of development (e.g., in the automotive industry), and they have only recently begun to be the focus of cost-reduction and standardization efforts. Today, most large-scale H2 electrolyzer plants share the distinction of being demonstration systems intended to showcase the technology—industrial, cost-oriented use is rare.

Together with electrolyzers and fuel cells, refueling stations are the third necessary component of a H2 ecosystem for mobility. While commercial transportation can rely on pre-planned driving routes—thus enabling refueling via a “hub-and-spoke” architecture—individual mobility requires a sufficiently dense network of public refueling stations, which does not exist today. As noted earlier, the good news is that the infrastructure required to deliver H2 fuel to these refueling stations on a large scale is far less challenging than that required for a similarly capable network of electric charging stations. Nonetheless, these H2 refueling stations simply need to be built. At least initially, this effort may need to be supported by publicly funded infrastructure projects.

Lastly, there is perhaps the most prominent disadvantage to using H2 in mobility applications: the high manufacturing costs associated with the constituent parts of these H2 ecosystems. A significant problem here is the lack of mass-production capacity, along with the costs of establishing the necessary industrialized production clusters. Although a sufficiently high level of technical maturity from a product development perspective already exists today, H2 technology systems have not yet reached the level of industrialization typical of large-scale production for conventional industrial or vehicle applications. The challenge, therefore, is no longer primarily to optimize efficiency down to the last detail using ever-evolving technologies or the latest materials. Rather, the challenge involves establishing volume production for these components that is stable and reliable. Accordingly, the necessary process development and quality standardization are the next logical steps toward cost-focused industrialization.

Takeaway. H2 will play a significant role in sustainable transportation, once battery-electric mobility has shown its limits in daily practice. In applications where heavier vehicles are required to cover long distances, H2 will serve as a highly effective complement to BEVs. Nonetheless, the attractiveness of this sustainable form of propulsion depends largely on the availability of green H2 and the economic feasibility of the respective H2 ecosystems. Among other factors, a key element involves the industrialization of components and subsystems for H2 technology. H2T

About the author

MATHIAS REUM is an expert in fuel cell technologies with more than 20 yr of industrial experience spanning research, development and strategic leadership. He earned a BS degree in environmental engineering with a focus on heat and energy systems from TU Bergakademie Freiberg and a Doctor of Science in electrochemistry at ETH Zürich, conducting research at the Paul Scherrer Institute. Dr. Reum served as a Project Manager at Schaeffler Technologies AG & Co. KG and later as the Head of the product group for fuel cells, eventually taking on strategic responsibilities as the Manager of the Strategic Business Unit Fuel Cell.