Articles

H2Tech: Tech Spotlight

TYLER CAMPBELL, Managing Editor

H2 PRODUCTION

hte conducts research for JGC on low-emissions H2 production

hte and JGC have collaborated on innovative technologies for converting ammonia into hydrogen (H2). The goal of this contract research project conducted at hte’s laboratories was to advance decarbonization by identifying suitable catalysts for ammonia cracking.

Ammonia cracking has attracted significant attention thanks to ammonia’s effectiveness as a H2 carrier. By cracking green ammonia, H2 can be produced on demand at the point of use, offering a clean and efficient energy solution. This process plays a crucial role in global decarbonization efforts, providing a scalable and sustainable pathway to reduced carbon emissions across key sectors such as transportation, power generation and heavy industry.

Recovering H2 through ammonia cracking requires high temperatures, safe handling of ammonia under high pressure and high-performing catalysts for efficient conversion. The 16-fold high-throughput unit selected for the project was specifically designed for demanding reaction conditions. This technology enabled catalyst testing under high temperatures and pressures, along with parallelized, rapid and comprehensive investigation of various catalysts and process parameters.

hte’s reactor design can selectively eliminate unwanted catalytic effects from reactor materials, allowing the catalyst’s activity to be studied in isolation within the kinetically controlled conversion range. Precise analytics ensure reliable results and the collection of industrially relevant data.

For more information, visit: https://www.hte-company.com/en/laboratory-systems/

Hanyang University researchers discover new breakthrough catalyst for cheaper green H2 production

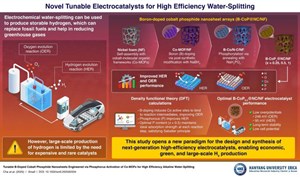

In a new study, researchers have developed novel, tunable boron-doped cobalt phosphide nanosheet-based electrocatalysts using metal-organic frameworks. These electrocatalysts offer high efficiency, low cost and long-term stability, with the potential to enable large-scale H2 production. Electrochemical water-splitting is a process that uses electricity to break down water into H2 and oxygen.

Unfortunately, large-scale H2 production using this method is currently infeasible due to the need for catalysts made from expensive rare earth metals. Among these, transition metal phosphides (TMPs) have attracted considerable attention as catalysts for the H2 generating side of the process, known as the H2 evolution reaction (HER), due to their favorable properties. However, they perform poorly in the oxygen evolution reaction (OER), which reduces overall efficiency.

In a recent breakthrough, a research team led by Professor Seunghyun Lee and Professor Dun Chan Cha, from the Hanyang University ERICA campus in South Korea, has developed a new type of tunable electrocatalyst using B-doped cobalt phosphide (CoP) nanosheets.

The researchers used an innovative strategy to create these materials, using cobalt (Co)-based metal-organic frameworks. They then subjected this material to a post-synthesis modification (PSM) reaction with sodium borohydride (NaBH4), resulting in the integration of B. This was followed up by a phosphorization process using different amounts of sodium hypophosphite (NaH2PO2), resulting in the formation of three different samples of B-doped cobalt phosphide nanosheets (B-CoP@NC/NF).

Experiments revealed that all three samples had a large surface area and a mesoporous structure, key features that improve electrocatalytic activity. As a result, all three samples exhibited excellent OER and HER performance. An alkaline electrolyzer developed using the B-CoP0.5@NC/NF electrodes showed a cell potential of just 1.59 V at a current density of 10 mA cm-2, lower than many recent electrolyzers. Additionally, at high current densities > 50 mA cm-2, it even outperformed the state-of-the-art RuO₂/NF(+) and 20% Pt-C/NF(−) electrolyzer, while also demonstrating long-term stability, maintaining its performance for more than 100 hr. Density functional theory calculations supported these findings and clarified the role of B-doping and adjusting P content.

For more information, visit: https://www.hanyang.ac.kr/web/eng/hanyang-university-institute-for-rise-seoul-

Sungrow Hydrogen, Wison Engineering launch MegaFlex Plant-as-a-Product for green H2 production

Sungrow Hydrogen and Wison Engineering have made waves in the green energy sector by jointly launching MegaFlex “Plant-as-a-Product”: a turnkey solution that reshapes green H2 production. Featuring MW-to-GW scalability and a fully outdoor modular design, this system overcomes traditional indoor plant limitations while enabling faster deployment and lower costs, setting new standards for the global H2 economy.

The solution redefines green H2 production through its large-scale, globally adaptable design. Combining standardized modular architecture with intelligent engineering, this innovative system embodies the Plant-as-a-Product philosophy—transforming conventional project-based construction into a replicable industrial model.

The complete turnkey package integrates core electrolysis equipment with plant-wide utilities and auxiliary systems: power supply, cooling systems, water treatment and intelligent controls. By significantly reducing delivery timelines, lowering construction costs and enhancing operational reliability, the solution establishes new benchmarks for efficient, economical and dependable green H2 production worldwide. The solution enables:

- Safe and reliable H2 production with flexible water electrolysis technology

- Quick setup and easy expansion [faster deployment through modular delivery and standardized design for accelerated return on investment (ROI), with seamless scalability from MW-to-GW levels]

- Significant reduction in onsite risks and acceleration of delivery via plug-and-play modular solutions.

At the solution's core lies Sungrow Hydrogen's water electrolysis technology, which delivers reliable outdoor operation through its weatherproof design. It features corrosion-resistant equipment with robust protection against extreme temperatures, water ingress, dust, corrosion, lightning and sunlight, enabling performance in challenging environments.

For more information, visit: https://en.sungrowpower.com/ProductsHome/69/hydrogen-equipment

H2 EQUIPMENT

GSE Solutions supports NuScale Power’s advances in H2 production using simulation

GSE Solutions has developed a H2 fuel cell generation and storage plant simulation model using its JTopmeret modeling to support a NuScale Power (NuScale) H2 simulator project. NuScale recently launched new research initiatives aimed at advancing integrated energy systems that can deliver both clean water and energy-efficient H2 production. Included is the development of an integrated energy system simulator for H2 production (high-temperature steam electrolysis mode), H2 fuel cell generation and H2 storage.

GSE Solutions, in collaboration with NuScale’s operations team, helped redesign the steam supply, H2 compression and heat recovery system control logic, utilizing GSE’s JTopmeret®, JLogic modeling technology and components of GSE’s JADE® high-fidelity simulation suite for the reversible solid oxide fuel cell (RSOFC). The RSOFC interfaces with the existing small modular reactor control room simulator at NuScale headquarters in Corvallis, Oregon (U.S.). The updated simulator enables NuScale to dynamically evaluate and optimize various configurations for a wide range of commercial-scale industrial applications that require > 200 metric tpd of H2.

For more information, visit: https://gses.com/systems-and-simulation/

SwRI advances fuel cell testing for more efficient H2-powered vehicles

Southwest Research Institute (SwRI) has developed new methods for evaluating the performance and efficiency of fuel cell technology in H2-powered vehicles without the need for test tracks or dynamometers.

SwRI’s novel controller system for H2-powered vehicles grants full authority over their fuel cell engines. Now, engineers can extract fuel cell stacks from a vehicle and rigorously test their reactions to both normal and extreme driving conditions without physically running the vehicle. These tests are driving the creation of algorithms to help ensure the performance and efficiency of these vehicles.

In H2-powered vehicles, fuel cells stacked together convert H2 gas into electricity through a chemical reaction—water and heat are the only byproducts. This makes these vehicles attractive for reducing carbon emissions while ensuring long range and short refueling times. SwRI’s controller system precisely manages the full range of the system’s operations, such as its fuel flowrates, air flowrates and temperatures. Being able to simulate different operations on the engine directly eliminates the need to run vehicles on roads for benchmarking and analysis.

The internally funded project began with a complete analysis of a H2 fuel cell-powered consumer vehicle to understand the internal mechanisms that run its system. The team then extracted the fuel stack from the vehicle and installed it in a controlled environment to assess performance.

Over the three phases of the project so far, SwRI has fully analyzed the stack configuration and developed new testing methods. The SwRI team is now focusing on developing predictive control models to improve fuel cell humidity management. Maintaining proper humidity levels enhances fuel cell performance. As the project continues, SwRI is exploring new control models and potential collaboration with commercial clients to test more complex, multi-stack setups designed for heavy-duty vehicles.

For more information, visit: https://www.swri.org/markets/automotive-transportation/automotive

H2 APPLICATIONS INNOVATION

PowerCell’s Marine System 225 receives Type Approval from Lloyd’s Register

PowerCell’s Marine System 225 has received Type Approval from Lloyd’s Register, which has confirmed that the Marine System 225 meets stringent international standards for safety, performance and design standards within the maritime industry. With this certification, PowerCell’s fuel cell system has now been given the greenlight for deployment on various vessels, enabling shipowners and operators to confidently adopt H2 electric technology.

Designed specifically for the marine environment, the Marine System 225 delivers 225 kW of efficient and vibration-free power. Its modular and compact structure allows for seamless integration into both newbuild and retrofit applications, making it ideal for ferries, workboats, patrol vessels and offshore support ships.

For these smaller vessels, often on shorter or fixed routes, fuel cells can serve as the main propulsion system. This allows them to eliminate greenhouse gas emissions and harmful local emissions such as sulfur oxides (SOx), nitrogen oxides (NOx) and particulate matter to improve air quality for passengers, crew and port communities.

For more information, visit: https://powercellgroup.com/segments/marine/

Purem by Eberspaecher produces and assembles parts for Topsoe’s solid oxide electrolyzer technology

Purem by Eberspaecher has produced and assembled parts for Topsoe’s solid oxide electrolyzer technology. The first solid oxide electrolysis cell (SOEC) pressure vessels have now been showcased at Purem by Eberspaecher’s plant in Neunkirchen, Germany. Consequently, Purem by Eberspaecher is contributing to Topsoe’s electrolysis technology for green H2. This underscores the exhaust and acoustics specialist’s commitment to developing new business areas.

Purem by Eberspaecher is developing solutions and technologies for a clean future in cooperation with strategic partners to open up new target segments in the constantly growing H2 market. Together with Topsoe, the company has developed a manufacturing concept for pressure vessels suitable for large-scale production. Topsoe’s SOEC technology is efficient in H2 production and addresses one of the major challenges of H2 as an energy source: its availability.

The principle of high-temperature electrolysis is highly efficient and has low energy requirements compared to known technologies. The SOEC pressure vessels form the centerpiece of the electrolysis technology as the chemical reaction to produce H2 takes place within them. Purem by Eberspaecher is one of Topsoe’s suppliers for the assembly of these vessels. The Esslingen, Germany-based company will assemble the vessel as well as produce additional steel parts.

For more information, visit: https://www.purem.com/en/clean-mobility/our-services

HyTANKa enables H2 refueling in the construction sector

ULEMCo has announced a major step forward in the practical decarbonization of construction operations with the launch of HyTANKa: a mobile H2 supply and refueling vehicle specifically engineered to address the operational challenges of energy delivery in off-road environments. Developed to replicate the role of the diesel bowser, HyTANKa provides a safe, flexible and self-contained solution to deliver fuel to the equipment rather than the equipment coming to the filling station. This is a key barrier to the deployment of H2-powered equipment within the normal operational requirements of a busy site.

The construction industry is recognized as one of the most challenging sectors to decarbonize, due largely to the high energy demands of machinery, the requirement for rapid and continuous operation, and the frequent absence of fixed energy supply during the early phases of site infrastructure development. While H2-powered equipment—dual-fuel, full combustion and fuel cell—is gaining interest as a practical ultra-low-emissions alternative to diesel, the absence of suitable onsite refueling mechanisms is a significant technical challenge.

HyTANKa addresses this gap by enabling mobile, high-pressure H2 delivery directly to construction machinery in the field. The vehicle is designed to operate autonomously and is equipped with a two-way booster system that allows for both the refueling of H2 machines at pressures up to 350 bar, and the filling of its own tanks from lower pressure sources such as manifolded cylinder pallets or higher volume onsite storage. The integration of these features allows HyTANKa to be independent of fixed power supplies or compression infrastructure, which is critical in the early phase of a site development or in remote construction environments.

HyTANKa is road legal under ADR regulations, allowing it to travel directly to H2 production facilities for filling and around the site in the same way diesel bowsers are used today. This operational flexibility offers construction operators the ability to manage H2 logistics in a dynamic, site-responsive manner. In keeping with its decarbonization purpose, the HyTANKa platform is itself powered by a H2 dual-fuel engine, reducing the overall carbon footprint of fuel logistics and further aligning with the broader sustainability goals of modern construction projects.

The HyTANKa has already been successfully demonstrated in live construction environments as part of the Element 1 project, partly funded by DESNZ, where it was used for the onsite refueling of 20-ton, dual-fuel H2 excavators. These real-world use tests confirmed the vehicle’s ability to deliver fuel loads within minutes, enabling uninterrupted machine operation and validating the platform’s suitability for routine use in demanding off-road conditions. With the capacity to refuel multiple machines per day, and to operate across dispersed or inaccessible locations, HyTANKa has proved it can match the service model of conventional diesel bowsers.

For more information, visit: https://www.ulemco.com/

TOYOTA GAZOO Racing unveils liquid hydrogen-fueled "GR LH2 Racing Concept" at Le Mans

TOYOTA GAZOO Racing has unveiled the GR LH2 Racing Concept, a liquid hydrogen (LH2)-fueled test car to advance the development of H2 technology in motorsports. As part of its efforts to produce ever-better cars through motorsports as the starting point, and to realize a carbon-neutral society, Toyota has advanced its technologies in the challenging environment of motorsports, including the Super Taikyu series in Japan. It has also accelerated its efforts to expand the production, transportation and use of H2—together with partners inside and outside the industry—towards the realization of a carbon-neutral society.

Toyota has taken on the challenge of H2 engine development in motorsports, initially through Rookie Racing’s participation in the Japanese Super Taikyu series with the H2-powered Corolla, which initially used gaseous H2 from 2021, before the introduction of a LH2-powered car from 2023. The potential of H2 engines in rallying was showcased in 2022 when the GR Yaris H2 completed demonstration runs at the Ypres Rally, a round of the FIA World Rally Championship.

In 2023, the H2-powered Corolla completed a demonstration lap of the Circuit de la Sarthe, while a H2 engine concept car, the GR H2 Racing Concept, was presented to preview a potential future H2 category at Le Mans. Since then, development of the technology has intensified, reaching a new milestone with the unveiling of the LH2-powered GR LH2 Racing Concept, which is based on the GR010 HYBRID Hypercar that participates in the FIA World Endurance Championship. Through future track testing, the GR LH2 Racing Concept will support Toyota’s continuous development of H2 technology and infrastructure, as well as help build relationships to expand the possibilities of H2 through the challenge of motorsports.

For more information, visit: https://toyotagazooracing.com/motorsports/ H2T