Articles

H2Tech: Tech Spotlight

TYLER CAMPBELL, Managing Editor

H2 PRODUCTION

Johnson Matthey’s CATACEL SSR boosts efficiency and cuts energy use

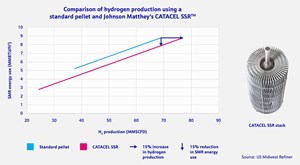

Johnson Matthey (JM) has unveiled new production performance data that shows the significant improvements in efficiency of existing steam methane reformer (SMR)-based hydrogen (H2) plants with the use of its catalyst, CATACEL SSR™. The key benefits of JM’s CATACEL SSR include:

- A 15% uprated H2 plant capacity

- A 15% reduction in SMR energy use per unit of H2

- A 5% reduction in natural gas consumption per unit of H2

- Easy drop-in installation

- Enhanced durability and heat transfer.

Lifecycle performances of CATACEL SSR in mid-sized and large H2 plants have now been validated and demonstrate an increase in H2 output by up to 15% with reductions in natural gas consumption per unit of H2. By reducing energy consumption and increasing feedstock efficiency, this catalyst introduces a way that H2 production can be scaled more responsibly and cost effectively.

Traditional pellet catalysts are replaced with uniquely engineered structures of thin metal foils, or “fans,” coated with catalysts through a proprietary process. These fans offer a greater surface area, higher durability and superior heat transfer, essential for high-temperature processes such as SMR. This simple drop-in solution requires no tube changeout for performance benefits, removes a bottleneck on SMR capacity and avoids more costly solutions to uprating existing H2 plants.

For more information, visit: https://matthey.com/products-and-markets/all-products

Mattiq and Heraeus partner to advance electrocatalyst innovation

Mattiq has formed a strategic partnership with Heraeus Precious Metals to develop and commercialize advanced electrocatalyst materials for green H2 production. The companies will engineer low-iridium catalysts to significantly reduce the amount of this rare and critical raw material for proton exchange membrane (PEM) water electrolyzer manufacturing before expanding into other innovative electrochemical solutions.

Iridium is indispensable for the green energy transition, as PEM water electrolysis—one of the most promising technologies for producing zero-carbon (green) H2—depends on its availability. Iridium is one of Earth’s rarest naturally occurring elements, making the efficient use of this critical resource a requirement to serve increasing demand for H2 production and other applications. With current iridium loading requirements, PEM electrolyzers will be limited in scale of annual deployment. Solutions are therefore needed to reduce iridium content in electrocatalysts without sacrificing performance.

In their collaboration, Mattiq and Heraeus Precious Metals will shorten the traditional research and development (R&D)-to-commercialization timeline, rapidly advancing low-iridium catalysts from prototype to industrial-scale solutions.

Together, the combination of cutting-edge R&D capabilities and world-class manufacturing will enable the two companies to radically reduce the cycle time of new innovations while delivering better results for their customers.

For more information, visit: https://mattiq.com/solutions

ADNOC Gas explores groundbreaking technology that turns methane into graphene and H2

ADNOC Gas has successfully installed British climate technology firm Levidian’s patented LOOP technology at the Habshan Gas Processing Plant. This marks the first-ever deployment of the technology at an operational gas processing site. Carbon will be captured from methane, the main constituent of natural gas, and transformed into graphene, a material set to shape the future of multiple industrial applications.

The LOOP unit is capable of producing more than 1 tpy of graphene and 1 tpy of H2, making it a dual-purpose innovation aligned with global energy transition goals. Future industrial-scale installations are expected to deliver 15 tpy.

Data collected during the pilot will be used to refine the ongoing development of AI modelling and digital twins to minimize energy consumption and maximize graphene output from future installations as part of Levidian’s growing fleet of LOOP units.

The graphene produced at the Habshan complex will be evaluated and utilized by ADNOC’s Technology team to explore possible applications. Graphene has the potential to be used across industries from enhancing the performance of electric vehicle batteries and solar panels to creating stronger, more durable materials such as concrete, tires and polymer pipes.

For more information, visit: https://www.adnoc.ae/en/our-products

H2 EQUIPMENT

New Emerson pressure relief valve optimizes safety and performance in critical gas applications

Emerson has introduced the Anderson Greenwood Type 84 pressure relief valve (PRV), specially designed to protect tanks and vessels used in H2 and other high-pressure gas applications. With Arlon® 3000XT thermoplastic seating and ASME SA-479 Type S21800 stainless-steel spindle material, the Type 84 PRV delivers exceptional leak-tight performance, resistance to embrittlement, optimum seat tightness, high reliability and long service life.

PRVs are frequently used in traditional applications, but they are not designed to handle extremely small molecules at very high pressures. Therefore, they are not ideal for H2 gas, which can diffuse into metals and cause embrittlement of PRV internals, increasing the risk of leaks, failures and safety problems.

To address these and other issues, Type 84 PRVs are constructed for high-pressure gas applications, with a range of 6,000 pounds per square inch gauge (psig) (413 bar gauge)–20,000 psig (1,379 barg) for H2 and He, and a range of 6,000 psig (413 barg)–21,756 psig (1,500 barg) for all other gases. The valves reach full lift at less than 5% overpressure to protect the vessel or tank to which they are affixed, with zero leakage at 90% of set pressure.

Type 84 valves feature a unique cartridge assembly design to apply uniform spring pressure, resulting in secure seat sealing and leak-tight performance. The valves are factory tested with helium and nitrogen, which are both accepted industry-wide as a substitute for H2.

Anderson Greenwood Type 84 valves comply with key industry standards for safety and performance, including American Society of Mechanical Engineers (ASME) Section VIII and XIII, National Board of Boiler and Pressure Vessel Inspectors (NB) certification, and American Petroleum Institute (API) 527.

To learn more, visit https://www.emerson.com/en-us/catalog/anderson-greenwood-series-60-80.

PSB Industries highlights Deox-H2 + TSA system for advanced H2 purification in oil and gas applications

PSB Industries’ Deox-H2 + TSA system is designed to meet the growing demands of H2 purification in the oil and gas industry. This fully customizable packaged skid offers an advanced approach to purifying H2 gas by removing both oxygen and moisture, helping oil and gas companies meet strict industry specifications.

The Deox-H2 + TSA system effectively handles inlet oxygen concentrations up to 4%, reducing oxygen levels to < 1 parts per million by volume (ppmv). In addition, it can process H2 gas with high moisture content, reducing water levels to < 1 ppmv. With the ability to operate under a wide range of conditions, including pressures from 100 psig─800 psig and temperatures from 10°C–149°C (50°F─300°F), the system is highly versatile and suitable for various oil and gas processing facilities.

Designed for minimal operator intervention, the fully automatic system integrates essential subcomponents, instrumentation and controls into a single efficient package. The inclusion of multiple regeneration strategies ensures zero gas emissions or losses, optimizing operational efficiency and sustainability in oil and gas operations. Additionally, the multi-layered adsorbent bed provides a cost-effective solution, reducing operating expenses (OPEX) while ensuring the highest level of purification for oil and gas processes.

For applications that do not require oxygen removal, PSB Industries offers a stand-alone Dryer package option, providing further flexibility to meet the specific needs of H2 producers.

PSB Industries manufactures and designs the Deox-H2 + TSA system in accordance with North American standards such as ASME, ANSI, NEC, UL, etc. and can further provide CRN registration for Canadian projects, ensuring it meets stringent industry standards for pressure vessels and safety. The system’s comprehensive design and customizable features make it a valuable asset for any H2 production facility.

For more information, visit: https://psbindustries.com/psb_hydrogen_bulletin/

John Cockerill achieves certification for H2-ready heat recovery steam generators

The shift towards H2 is key to achieve climate neutrality and support the energy transition in power generation, with the target of net-zero emissions by 2050, as outlined in the EU Green Deal. John Cockerill has been awarded a concept certificate from TÜV-SÜD for the H2-readiness of its heat recovery steam generators (HRSGs).

The EU already integrates H2 in its energy mix and many countries will therefore inevitably phase out fossil fuels. From this perspective, H2 is a highly reliable potential fuel for combined-cycle power plants and will have a key role to play in power generation.

Considering its enormous advantages, oil ang gas companies are gearing up to use H2. New and existing natural gas-fired, combined-cycle power plants are expected to fully operate on H2 or other fuels blended with H2. They must, therefore, be H2-ready.

After having established a guideline to define the H2-readiness of power plants and their related equipment, TÜV-SÜD, as an independent third-party, proposed the certification for original equipment manufacturers (OEMs) and engineering, procurement and construction (EPC) companies. These guidelines and certification can encompass an entire power plant with all relevant sub-systems.

John Cockerill has modified its heat recovery boiler design to allow them to operate with H2 instead of fossil fuels. John Cockerill’s HRSGs are steam generators that recover heat from hot flue gasses at the outlet of gas turbines. The heat is transformed into steam to feed a steam turbine and produce power or a combination of power and heat. The company’s HRSGs enhance the efficiency of power plants while reducing emissions for each produced megawatt.

The award of a concept certificate from TÜV SÜD for the H2-readiness of its HRSGs for combined cycles and cogeneration applications, with drum-type and once-through boiler designs, confirms that John Cockerill’s H2-readiness concept for the bidding phase of new projects meets the guidelines requirements and that its HRSGs are ready to operate with up to 100% H2. This certificate covers vertical and horizontal technologies with or without supplementary firing, and potentially the use of fresh air firing, for new and retrofitted concepts.

For more information, visit: https://services.johncockerill.com/en/

Plug Power launches spot pricing for green H2

Plug Power has introduced the first-ever spot pricing program for liquid green H2, marking a major step forward in the industry. H2 buyers now have the freedom to purchase liquid green H2 from Plug’s production plants on-demand and without the limitations of long-term take-or-pay agreements. The flexibility provided by this new spot market allows customers like retailers, industrial manufacturers and power plant operators to optimize their H2 sources efficiently and react swiftly to fluctuating energy demands without being tied down by long-term contracts.

In an early sign of success, Plug has entered into spot pricing agreements with several key industry players. Among these, a spot agreement with one of the largest industrial gas companies underscores widespread industry endorsement. Looking forward, the ripple effects of this innovative pricing model could redefine supply dynamics and cost structures across the entire green H2 ecosystem.

Each Thursday, S&P Global Platts will publish a price for the following week based on Plug’s supply and demand. Customers must have a spot agreement in place with Plug. If customers want to purchase H2 at the published price, Plug will execute a transaction agreement to accept a customer tanker at one of its plants.

All Plug operating plants in Woodbine, Georgia, Charleston, Tennessee and St. Gabriel, Louisiana (U.S.), with a combined liquid H2 production capacity of approximately 45 tpd, participate in the spot pricing program. Plug, the third-largest producer of liquid H2 in North America, is the only producer of liquid green H2 on a commercial scale.

Plug will submit data to Platts, part of S&P Global Commodity Insights, for publication in its H2 daily publication and clean energy technology service to help improve transparency in the North American spot H2 market. Platts publishes market information including, but not limited to, firm bids and offers, expressions of interest to trade and confirmed trades that are received from market participants throughout the day, published as “heards.” This information is published in real time as it is received on Platts information services and is used to underpin Platts price assessments. Companies that wish to access Platts H2 price assessments must have a license agreement with S&P Global Commodity Insights. Customers that wish to buy H2 from or sell H2 to Plug must have a spot agreement in place with Plug.

For more information, visit: https://www.plugpower.com/fuel-cell-power/

H2 APPLICATIONS INNOVATION

Alpha H2 launches trial of on-demand H2 injection system with two major Mexican transport companies

Alpha H2 Ltd., a supplier of H2 on-demand injection systems, has begun trials with two major Mexican transport companies. The key highlights include:

- The first trial is being conducted on a truck from Traxión, one of Mexico’s leading mobility and transport providers, which operates a fleet of 10,900 vehicles.

- The second trial is being conducted on a bus from the country’s largest interstate transport company, which manages a fleet of 1,500 vehicles.

- Both trials represent a significant pipeline of 12,400 vehicles.

Alpha H2’s cutting-edge kits convert water into H2 on board the vehicle, which mixes with fuel to reduce emissions and fuel costs. Its units can be used for all types of engines and applications, including trucks, boats, cars, generators, utes, vans and heavy machinery.

The trials will evaluate Alpha H2’s technology for reducing emissions and fuel consumption and assess how seamlessly it integrates into both companies’ existing operations. If the trial is successful, orders are expected to follow.

This trial marks a major step in Alpha H2’s expansion into the Latin American market, where the company has a growing sales pipeline. Conducted in partnership with United H2 Ltd.’s joint venture partner in the region, GreenH2 LATAM, the trial demonstrates Alpha H2’s potential to deliver scalable fuel reduction solutions worldwide.

GreenH2 LATAM and Alpha H2 are deploying H2 injection systems across Mexico, Ecuador, Panama, Peru, Chile, Colombia, the Dominican Republic, Argentina, Brazil and Spain. Additionally, recent third-party testing has validated the effectiveness of Alpha H2’s technology, aligning with previous results and confirming the system’s environmental benefits. The results were:

- A 20% reduction in fuel usage

- A 13% reduction in CO2 emissions

- A 16% reduction in hydrocarbon emissions.

Further expanding its global presence, Alpha H2 also recently secured an agreement with an African distributor to introduce its on-demand H2 kits across Botswana, South Africa, Namibia, Zambia, Zimbabwe, Angola, the Democratic Republic of Congo, Tanzania, Rwanda and Ghana.

For more information, visit: https://alphah2.com/#applications H2T