Articles

H2Tech: Tech Spotlight

T. CAMPBELL, Managing Editor

H2 PRODUCTION

James Cropper to deliver fully integrated bipolar plate for HOERBIGER's PEM electrolyzers

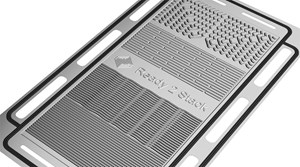

James Cropper, an advanced materials, paper and packaging group, has entered into a strategic collaboration with HOERBIGER to deliver Ready2Stack™, a fully integrated bipolar plate (BPP) solution for proton exchange membrane (PEM) electrolyzers used in hydrogen (H2) production.

The solution addresses key barriers to the scale-up of H2 production by consolidating all design and manufacturing processes in the production of BPPs—a critical component within PEM electrolyzers—into a single point of supply. This reduces complexity, improves quality and reduces the overall cost of H2 production.

Combining James Cropper’s advanced electrochemistry and coating expertise and HOERBIGER’s industrial-scale manufacturing, metal forming and automation capabilities, Ready2Stack delivers reduced production downtime and enhances long-term reliability, making green H2 more accessible and commercially viable. It offers a differentiated solution for original equipment manufacturers (OEMs) seeking to simplify supply chains, optimize their offerings and accelerate green H2 ambitions.

For more information, visit: https://advancedmaterials.jamescropper.com/market/pem-water-electrolysis/

Unlocking a new source of clean H2 from UK wastewater

A project to use gas from sewage waste to produce clean H2 is being delivered at United Utilities’ wastewater treatment works in Manchester, UK. The water company has joined forces with a Cambridge-based climate tech firm Levidian to demonstrate the opportunity for biogas produced from wastewater to create H2 and super-material graphene—the thinnest and strongest known material.

Supported by the Department for Energy Security and Net Zero’s H2 BECCS Innovation Program, Levidian’s LOOP device uses electromagnetic waves to split methane gas (CH4) into H2 and carbon, capturing the carbon in solid form as graphene. The lower carbon blend gas is then fed into United Utilities’ onsite generator where it is burned to help power the site.

The graphene produced has numerous use cases, from extending the life of tires and driving down the carbon footprint of concrete, to boosting the performance of batteries and solar panels or creating cut resistant fibers.

Research by the firms has identified the opportunity for biogas generated from sewage waste to be used as a fully sustainable feedstock to produce up to 75,000 metric tons per year (tpy) of H2—enough to fuel more than 40% of all UK bus and coach journeys.

Potential uses for H2 include a clean fuel for industrial processes, zero-carbon transport such as heavy goods vehicles (HGVs) or being blended into the national gas network to reduce emissions associated with heating homes and cooking on gas.

For more information, visit: https://www.levidian.com/graphene

Hinicio introduces ANDREA: An optimization and simulation tool for Power-to-X projects

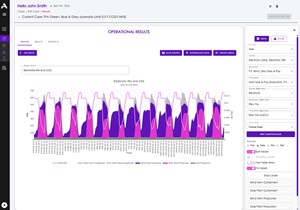

Hinicio has launched ANDREA: an advanced optimization and simulation tool designed for Power-to-X projects. Power-to-X projects require a system engineering approach supported by advanced tools, robust data and expert insights. ANDREA was developed to help industry professionals navigate this complexity, assess techno-economic feasibility and seamlessly integrate regulatory and environmental factors into the optimization process.

ANDREA is built on a systemic approach, analyzing the entire system to identify synergies across different processes. While it supports 8,760-time-step modeling, its open time-step architecture allows for fully flexible temporal resolutions, enabling simulations that range from multi-year analysis for strategic planning and technology optimization to minute-level precision for evaluating operational feasibility. This flexibility ensures accurate representation of system dynamics while effectively detecting and mitigating bottlenecks and operational risks.

With a track record of more than 100 Power-to-X projects, 9,000 cases analyzed and 4,000 hr of computation, ANDREA stands out as a versatile solution for applications in mobility, H2, ammonia, eFuels and chemical installations. The key advantages of ANDREA include:

- Tailored for Power-to-X: Model unlimited system architectures with speed, precision and ease

- Optimized for success: Analyze costs, maximize revenues and identify the most competitive configuration for your project

- Flexible time resolution: From long-term sizing to minute-level feasibility, adjust models to match a project’s needs

- Integrated policy and regulation: Reduce risk through optimization while considering market and regulatory constraints according to target markets.

For more information, visit: https://hinicio.com/andrea/

Haffner Energy unveils Hynoca Flex 500 IG: A flexible, cost-effective alternative to gray H2 and fossil fuels

Haffner Energy has introduced Hynoca® Flex 500 IG, a line of H2 production units capable of producing 12 tpd of green H2 to be delivered under €3/kilograms (kg) without subsidies. Hynoca Flex 500 IG also enables the production of cost-competitive renewable electricity to manage fluctuations in H2 demand or ensure energy autonomy.

Thanks to the existing subsidies, grants and/or tax credits available in most developed countries, green H2 is now cost-competitive with gray (fossil-based) H2, while providing significantly more flexibility and delivering a carbon-free solution. Not only does H2 and electricity cogeneration provide a unique solution for managing fluctuating H2 demand, but it can also ensure the energy autonomy of the system or even create opportunities in off-grid locations.

Hynoca Flex 500 IG provides flexibility, optimized energy efficiency (80%) and near-independence from power grids, making it a scalable decentralized alternative to gray H2 and fossil fuels. The technology is modular and standardized, which ensures reliable and replicable deployment at scale. Hynoca Flex 500 IG combines performance and modularity to meet industrial and mobility needs:

- Flexible production, requiring minimal or no grid dependency

- Optimization of capital expenditures (CAPEX) and operational expenditures (OPEX), ensuring that H2 can be commercialized at < €3/kg without subsidies, and with > 80% energy efficiency, maximizing process performance

- Rapid deployment, free from grid infrastructure constraints

- Standardized design, ensuring predictable performance and simplified integration.

Hynoca Flex 500 IG also generates highly competitive synthetic gas (syngas), the precursor to H2. Its low cost opens up new economic opportunities beyond H2 production.

- Profitable peak-hour electricity generation: The cost of syngas is so competitive that it enables power production during peak hours, making it an economically viable solution to balance H2 demand fluctuations.

- Operational security without rigid contracts: This flexibility allows plant operators to maintain stable production without requiring rigid offtake agreements.

By combining H2 and electricity generation, Hynoca Flex 500 IG ensures continuous operation, optimizing revenue streams and enhancing economic resilience, making final investment decisions (FIDs) easier.

A strategic complement to electrolysis and power-to-liquid (PTL). Each Hynoca Flex 500 IG unit generates 58,000 tpy of biogenic carbon dioxide (CO2), a key resource for PTL (eFuels) production and a critical enabler for H2 from electrolysis.

- 58,000 tpy of renewable CO2 can convert 5,230 tpy of H2 into 42,000 tpy of eMethanol [or 18,000 tpy of eSAF (sustainable aviation fuel)], which is easy to transport and store

- 5,230 tpy of H2 is produced by 60 megawatts (MW) of electrolyzer capacity (4,000 hr/yr load factor)

- Strategic synergy between Hynoca Flex 500 IG and electrolysis plants, structuring the H2.

Hynoca Flex 500 IG delivers competitive H2 and supports the expansion of electrolysis by providing a reliable source of competitive biogenic CO2.

Proven, standardized technology for industrial scale deployment. Hynoca Flex 500 IG builds on Hynoca technology, already operational at the Center for H2 Production, Testing and Training in Marolles, France. This unit has been producing H2 that meets mobility standards. Scaling up this technology ensures industrial continuity with no technical risks, optimizing implementation for large-scale projects.

The Hynoca process accepts all possible organic renewable feedstocks, including agricultural residues, sludge, manure, municipal sorted waste and woody byproducts, supporting a circular, low-carbon economy with a near-zero carbon footprint. Compatibility with all organic feedstocks means considerably lower costs, while simultaneously improving supply security. Each Hynoca Flex 500 IG unit consumes approximately 31,000 tpy of dry plant-based biomass.

For more information, visit: https://www.haffner-energy.com/renewable-hydrogen-solution-hynoca/

H2 EQUIPMENT

Alleima launches onsite tubing solution in Canada for H2 projects

Alleima has introduced an onsite tubing solution in Canada—a mobile machine capable of straightening and cutting thick-walled coiled tubing directly at the construction site. This innovative solution changes how coiled tubing is supplied across the country, particularly for the installation of H2 refueling stations. By bringing the equipment to the job site, Alleima streamlines the setup process and eliminates the need for offsite processing.

It has a strong track record in Europe, supporting more than 70 H2 refueling station projects. Alleima’s mobile unit offers a versatile, cost-effective alternative by delivering tubing cut to exact specifications on demand, wherever needed. Utilizing a 20-ft container platform, the mobile unit is operated by Alleima experts trained in handling high-pressure thick-wall coils up to 1 in. Key benefits include:

- Onsite manufacturing: Direct-to-customer precision cutting and straightening

- Versatile deployment: Adaptable to a range of terrains and extreme conditions

- Enhanced safety and compliance: Seamless tubing solutions meet strict H2 industry standards

- Minimized waste: Precision monitoring and control allow for any length to be cut as needed

- Faster installation: Significantly reduced setup and delivery times.

For more information, visit: https://www.alleima.com/en/products/tube-pipe-fittings-and-flanges/

Asahi Kasei, Nobian, Furuya Metal and Mastermelt commence project to recycle metals from electrolyzer components

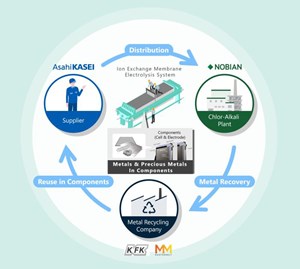

Japanese technology company Asahi Kasei has started a joint demonstration with Nobian, Furuya Metal and Mastermelt on the recycling of metals, including precious metals, used in the cells and electrodes incorporated in electrolyzers used for the production of caustic soda. Through this initiative started in February 2025, the partners will work towards building a recycling ecosystem for valuable metals in the chlor-alkali industry.

For nearly five decades, Asahi Kasei has been involved in the field of chlor-alkali electrolysis for the production of caustic soda and chlorine. The company manufactures and supplies ion-exchange membranes, electrolysis cells, electrodes and operation expertise for electrolyzer plants. Electrolyzers apply an electric current that is used to split salt water (brine) into chlorine, H2 and caustic soda, which are then used in various chemical products.

Precious metals such as iridium and ruthenium are used to produce electrodes and other components for electrolysis systems. With increasing global demand for these materials, Asahi Kasei has been advancing initiatives with partners to ensure a stable and secure supply of these metals. One such example is a demonstration project of an electrolysis cell rental service in Europe. Operating since 2023 in collaboration with Nobian, a manufacturer of caustic soda and other essential chemicals, this project focuses on the reuse of precious metals.

Asahi Kasei’s joint recycling project with Nobian, as well as with recycling specialists Furuya Metal and Mastermelt, aims to establish a recycling process inside the chlor-alkali industry that refines metals from cells and electrodes that have reached the end of their service lives and reuses them as raw materials for the production of new components within the industry. It is expected that this may also be applied to components of Asahi Kasei’s electrolysis system for producing green H2 using clean energy.

In this project, Asahi Kasei will first collect end-of-life electrodes from Nobian and provide them to Mastermelt and Furuya Metal, which will perform the removal of the catalyst from the electrodes, prepare the material for the next process step, and extract and purify the precious metals from the catalyst. In the final step, Asahi Kasei uses the precious metals for a new catalyst, which is then utilized for the coating of electrodes. By using these recycled catalytic electrodes, Nobian will conduct brine electrolysis, thereby enabling resource recycling in the production of caustic soda and chlorine.

For more information, visit: https://chlor-alkali.asahi-kasei.co.jp/en/

H2 APPLICATIONS INNOVATION

Plant leaves inspire design of improved fuel cell

H2 fuel cells convert H2 and oxygen into electricity, heat and water. Because this conversion process does not generate carbon emissions, fuel cells are seen as a valuable source of green energy that could be key in addressing climate change.

However, an obstacle is standing in the way of their use in large-scale applications (e.g., powering electric trucks for long-haul transport or replacing diesel generators to provide electricity in remote, northern communities). Today’s fuel cells have reached a ceiling in the amount of electricity they can generate because their internal structure cannot adequately manage all of the water that cells create as a byproduct.

Researchers from the University of Toronto’s Department of Mechanical and Industrial Engineering looked to a novel source when they were brainstorming for ideas to improve the design of the channels (called flow fields) that direct water inside the cell. In this case, the process was moving water in a single direction. Researchers found evidence of this on the skin of lizards and the leaves of certain plants.

“Lizards living in dry, arid climates have scales that have evolved to trap condensation from air and channel it to their eyes and mouth,” said PhD student Eric Chadwick. “Similarly, on certain types of leaves the veins catch water and move it to tips of the leaves so that it falls down, so the roots can absorb it.” He and his team incorporated these patterns from nature into the channels within their new cell, to more effectively move water from the porous layer inside the cell to the outside of the cell.

Using the Canadian Light Source at the University of Saskatchewan, the researchers found that the nature-inspired design resulted in a 30% increase in the peak power density in the fuel cells, compared to existing designs. The new cell design showed a more even distribution of water within the cell, with no build-up, which also meant a more even distribution of the reactants (oxygen and H2), enabling the fuel cell to use the catalyst (platinum) more effectively. The researchers also found that, because the new design removed excess liquid water from the porous layer, the channels served as additional pathways for more reactant to get to the catalyst layer.

For more information, visit: https://www.lightsource.ca/public/news/2025-26-q1-apr-jun/plant-leaves-inspire-design-of-improved-fuel-cell.php

Yanmar Power Technology secures approval in principle (AiP) for maritime H2 fuel cell system from DNV

Yanmar Power Technology Co. Ltd., a subsidiary of Yanmar Holdings, has received an AiP for its GH320FC Maritime Hydrogen Fuel Cell System from the classification society, DNV. The GH320FC is designed as a next-generation power source for marine applications with an innovative design that facilitates easy installation on various types of vessels. The system also allows for multiple units to be connected in parallel and offers flexibility in the number of H2 fuel cell modules, enabling it to meet diverse power requirements across different ship types and operations.

For more information, visit: https://www.yanmar.com/global/about/

H2 STORAGE AND TRANSPORTATION APPLICATIONS

CB&I and Shell demonstrate commercial-scale liquid H2 storage tank design for international trade applications at NASA

CB&I and a consortium including Shell International Exploration and Production Inc. (Shell), a subsidiary of Shell plc, GenH2 and the University of Houston have announced the completion of a first-of-its-kind, affordable, large-scale liquid hydrogen (LH2) storage tank concept at NASA's Marshall Space Flight Center (MSFC) in Huntsville, Alabama (U.S.), that will enable international import and export applications.

The project, which began in 2021 and is supported by the U.S. Department of Energy (DOE), developed a novel non-vacuum tank design concept for large-scale (up to 100,000 m3) storage of LH2 that is anticipated to provide a substantial cost advantage over conventional vacuum insulated tanks. This concept is being demonstrated through the construction, startup and testing of a small-scale LH2 demonstration tank at NASA MSFC.

The demonstration tank will significantly increase the MSFC H2 test facility's LH2 storage capacity and be used to characterize the behavior of materials under cryogenic conditions, mimicking normal fill and empty cycles and testing non-vacuum insulation materials. In addition to an estimated 6-mos test period included in the project scope, a Space Act Agreement among the partner organizations provides for MSFC's use of the tank over a 5-yr period, during which CB&I and Shell will continue to test new insulation technologies under non-vacuum conditions.

For more information, visit: https://www.cbi.com/product-lines/cbi-low-temperature-cryogenic-storage/

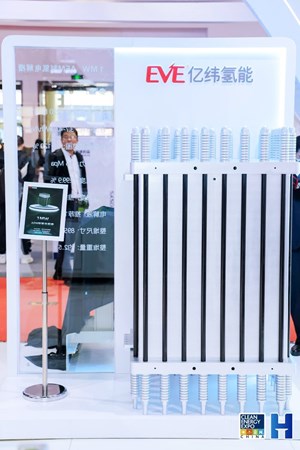

EVE Hydrogen Energy showcases multi-scenario, MW-capacity H2 energy storage solutions

EVE Hydrogen Energy has launched a 1-MW anion exchange membrane (AEM), supporting the achievement of China's carbon neutrality target and 14th Five-Year Development Plan. EVE Hydrogen Energy's electrolyzer is revolutionizing industry standards through three breakthroughs:

- Integrated flow field design: Achieves 75%─80% low heating value (LHV) efficiency and a > 60,000 hr duty cycle

- Advanced electrode: Realizes 5.0 A/cm2 energy density through a 20% increase in current density

- Compact form: Saves up to 30% space on large-scale projects.

With an output power of 230 Nm3/hr at 4.6 kWh/Nm3–4.8 kWh/Nm3, the electrolyzer surpasses the single stack power constraints. The non-precious metal catalyst designed by EVE Hydrogen Energy and the ion-conductive membrane save 40% of the cost compared to the PEM method, and localization reaches 95%. Operating at 1.4 MPa after a 15-min cold start, the electrolyzer supports volatile renewable energy sources and high-pressure industrial needs.

Changing usage scenarios: Complete ecosystem solutions for every need. EVE Hydrogen Energy’s MW H2 storage solution combines an AEM electrolyzer with photovoltaic (PV) and energy storage (powered by EVE Lithium Energy). Key features include:

- Dynamic power matching: Increased renewable energy utilization by 35%

- Peak-valley arbitrage: Creating a closed-loop “production-storage-application” system.

For more information, visit: http://en.evehydrogen.com/product/product_center.html H2T