Articles

Partial oxidation technology for clean fuel generation

Process/Project Optimization

J. KASSMAN, S. YAN and J. ZHOU, Air Products, Houston, Texas (U.S.)

Partial oxidation (POx) technology-enabled process solutions are well positioned to solve several energy transition challenges. Standout features of the technology include attractive lifecycle economics, unique and adaptable feed flexibility, a range of heat recovery options, high inherent carbon capture, long life equipment and phased carbon dioxide (CO2) sequestration—all of which enable a smooth transition to low-carbon intensity hydrogen (H2).

Numerous organizations and countries globally are actively engaging in initiatives to advance and execute decarbonization projects aimed at achieving environmental sustainability. Examples of this include the European Union (EU) Innovation Fund and U.S. 45Q tax credit initiative supporting industrial decarbonization projects in the regions. Blue H2 can play a pivotal role in global decarbonization by supplying low-carbon H2 for opportunities such as clean fuel production or onsite decarbonization for the existing operating plants. The authors' company’s POx-based Louisiana clean energy project is designed to produce more than 750 million standard cubic feet per day (MMft3d) of low-carbon H2.

Among the various low-carbon H2 generation technologies, POx technology is a simple and robust option to readily tailor into plant level clean energy initiatives. With technology originally developed by Texaco in the 1940s, the author's company brings more than eight decades of gasification technology expertise with more than 300 gasifiers designed and licensed globally across various feedstocks. Today, there are two dozen licensed POx-based gasification plants in operation (FIG. 1).

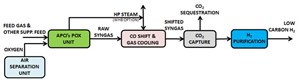

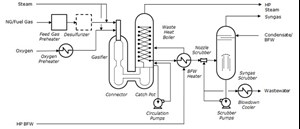

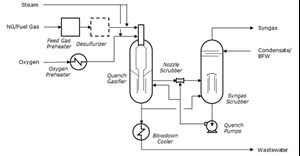

Gaseous hydrocarbons and supplementary feeds are fed to the POx reactor along with oxygen through a process feed injector. The feed streams react inside the POx reactor at high pressure and high temperature to generate a raw synthesis gas (syngas) containing mainly H2 and carbon monoxide (CO). Depending on the heat recovery design concept, syngas is either quenched in a water pool or routed to a waste heat boiler (WHB) for high-pressure steam generation.

The syngas is further treated in a water scrubbing system for removal of small amounts of soot (unconverted carbon) before exiting the POx unit. Depending on the desired ratio of H2/CO for a given application, an appropriate amount of syngas is sent to a CO shift reaction section. The CO2 present in the syngas is absorbed in a CO2 capture unit before sending it to an optional H2 purification section. Captured CO2 is taken for sequestration and the final product from the purification unit is taken as low-carbon H2.

POx technology. The following are the salient features of the author’s company’s POx technologya:

- Non-catalytic process based on POx of various gaseous hydrocarbon feed with pure oxygen to produce syngas

- Ability to co-feed liquid residues

- No or minimal feed pretreatment requirement

- POx reactor is unaffected by the presence of sulfur in the feed

- Downward entrained flow refractory lined reactor with an operating pressure range from 20 barg–87 barg

- Heat recovery options include direct quench and steam generating WHB designs

- Typical methane slip for POx is ~0.2% vs. ~1.0% to 10% for the alternative technologies

- No process steam requirement for gas feed operation

- No catalyst used in the process, allowing POx to use various feedstocks without needing a pre-reformer while lowering the process complexity and maintenance cost

- High-pressure operation results in a smaller footprint and reduces or eliminates additional syngas compression cost

- The CO2 capture rates can be as high as 99%, resulting in low carbon intensity. This is possible to achieve as all the CO2 produced is contained in the high-pressure process stream with the absence of carbon emitting units such as fired heaters or pre-reformers

- Minimal soot formation that is easily handled using an efficient syngas scrubbing process

- Faster plant ramping rate capability than catalytic reforming process technologies.

The evolution of gasification technology. The author’s company's POx technologya is part of the company’s suite of gasification technologies, which has a long history of proven operation over decades of operation. POx gasification technology was developed at Texaco’s Montebello research laboratory in 1946, with the first commercial plant in 1952. Since then, there have been 55 plants designed and licensed using the POx technology. The company began operating a POx plant in 1996, and the plant continues to operate today (FIG. 2).

POx technology offerings. The author’s company offers POx technologya to potential projects under a Sale of Gas (SOG) mode supply option or a technology license/technical services option. The SOG option takes advantage of the synergies the company can bring as an experienced provider and operator of H2 and pipelines, and air separation unit (ASU) plants.

The SOG option provides a complete build, own and operate POx gasification plant. The plant scope includes receiving feedstock, utilities and supplying the final product, and possibly byproducts (e.g., steam), to the end user at a prescribed price over a contract period of 15 yrs–20 yrs.

Technology licensing includes a process design package (PDP), granting rights to use the technology and supplying performance critical proprietary equipment. Technical services offered include startup and commissioning support, existing plant retrofits, feed conversion activities and more.

WHY CHOOSE POx TECHNOLOGY?

Feedstock flexibility. POx technologya is highly suited to processing various types and compositions of gaseous feedstock in the facility since the base design is minimally impacted by feed variations from simple methane to heavy residual compounds. The technology’s ability to co-feed non-standard liquid feedstock residue is another key differentiator in achieving economic and decarbonization goals. Feed flexibility allows for an optimized use of available low-value streams in the facility which otherwise would go to flare or fired heaters, causing direct carbon emissions.

Adaptability over plant lifecycle. The robust design makes it adaptable to changes in feedstock over the life of the plant. This flexibility has enabled some licensee plants to run for > 40 yrs by adapting to changes in feedstocks economics over time. These include changes in feedstock specifications and, in some cases, changes in primary feed from gaseous feed to liquid feed or vice versa through limited modifications to the feed system and burner retrofits. POx technologya equipped with its inherent feed flexibility and adaptability, aptly solves the challenges that industrial decarbonization initiatives experience during the project lifetime and beyond.

FEEDSTOCK PRETREATMENT

Feed preheating. Feed preheating is not a mandatory requirement to accomplish the POx reactions, unlike the competing reforming technologies. By eliminating the need for a fired heater to preheat the feed, costs can be reduced and carbon intensity can be improved. Process optimizations may include capturing heat from downstream processes to improve efficiency and reduce oxygen demand.

Feed gas desulfurization. The POx process can tolerate the presence of sulfur in the feed. If the downstream process units require a syngas with no sulfur, the POx process has the flexibility to employ a desulfurization unit upstream or downstream of the POx reactor.

Feed vaporization. POx technology’s unique capability in handling liquid phase supplementary feed along with gaseous primary feed can be accomplished without any requirement for feed vaporization. This simplifies the incorporation of heavier feeds along with the gaseous feed that would be impossible for competing reforming technologies.

High-pressure POx operation. The author’s company’s POx processa is unique in that the POx design operating pressure can be as high as 87 barg (1,262 psig). Commercially operating licensed POx plants supporting ammonia production reduced or eliminated the need for H2 gas compression.

High-pressure operation also helps to reduce plot area with smaller size equipment while producing the same amount of the product syngas.

Steam or CO2 as a reactant. This process does not generally require steam as a reactant; however, the POx process can use steam or CO2 as feed to adjust the syngas H2/CO ratio in the range of 1.0–2.0 to optimize for the downstream process requirements. Implementing a CO2 recycle process to the POx reactor achieves the following sustainability goals:

- Reducing primary gas (natural gas) consumption

- Maximizing or meeting CO yield in the syngas based on the downstream process requirements

- Minimizing carbon footprint by consuming CO2 in the POx reactor which otherwise would have left as an emission.

Heat recovery design flexibility. POx technology offers the following heat recovery options to align with project steam requirements: WHB and direct water quench. Projects with a high value for steam generation or high-cost power can opt for the WHB design option, producing high-pressure steam for process and utility usage. Conversely, the direct quench design option offers a lower capital cost feature to yield an economic value to the product. These design options enable users to navigate for the best process configuration and achieve an optimum economic solution.

Lower methane slip in syngas. The presence of methane (CH4) in syngas often affects the performance and economics of downstream units. High levels of CH4 in process gas circulation loops impact the operation of cold box units, purging requirements and carbon capture. The high-temperature operation of the POx process limits CH4 slippage to the low levels desired by the downstream processes. Process yields of CH4 lower than 0.5 mol% (dry basis) in the syngas are readily achieved, giving the flexibility of meeting overall carbon capture requirements without the need of additional process units for flue gas CO2 absorption (FIGS. 3a and 3b).

Takeaway. Compared to catalytic reforming processes, POx plants contain process equipment simpler in build and fewer in number. This helps the plant to achieve relatively higher reliability, and lower operating and maintenance costs. The maintenance turnaround for a POx unit is less labor intensive due to the absence of catalyst handling and complex equipment internals.

A further benefit resulting from the non-catalytic feature of the POx technology is a lower sensitivity to process transients due to plant load changes, allowing a ramp rate that can be 5–10 times faster than that achieved by catalytic processes.

The inherent ability of the author’s company’s POx technology is to capture up to 99% of the CO2 produced in the plant directly from the syngas, enabling a high degree of flexibility in a phased approach to CO2 sequestration, and allowing for a ready transition from a traditional gray H2 plant to a low-carbon H2 facility with the addition of CO2 compression or liquefaction equipment. H2T

Note

a Air Products’ SynFlexTM POx Gasification Technology

About the authors

JERRY KASSMAN is the Director of Technology Licensing for Air Products. He is responsible for licensing all Air Products’ gasification technologies, including its POx technology globally. Kassman has 38 yrs of experience in gasification ranging from R&D to technical services, plant operations, plant management, licensing and commercial leadership. He is the coauthor on more than a dozen papers and eight patents.

JOHN ZHOU is the Senior Manager in Air Products’ Product and Project Development organization. He supervises the global technical team for Air Products’ technology portfolio, including its proprietary POx and slurry gasification processes. Zhou has more than 20 yrs of direct experience in gasification and related areas, including process and component design, proposal development, product management, commissioning and startup support, revamping, and technology licensing. Zhou earned a PhD in chemical engineering from Wayne State University.

SEAN YAN is the Blue Hydrogen Product Manager for Air Products’ Product and Project Development organization. Yan oversees the development of blue H2 plant products based on Air Products’ technology portfolio with a special focus on its proprietary POx processes. He has 20 yrs of direct experience in H2 production, purification, gasification and related areas, including process design, commissioning and startup support, revamping, technology licensing, packaged equipment sales and product development. Yan earned a PhD in chemical engineering from the University of Utah.