News

Ionomr releases hydrocarbon membrane and polymer set to disrupt heavy-duty fuel cell applications

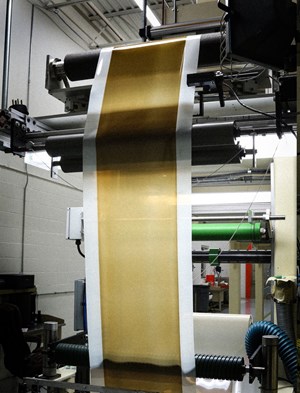

Ionomr Innovations released its breakthrough Pemion hydrocarbon-based proton exchange membrane and polymer, marking a revolutionary advance in materials for green H2 fuel cell applications for heavy-duty industry. Pemion is used in large fuel cell applications including heavy-duty transport, automotive, and stationary power, offering superior chemical and mechanical stability, conductivity, durability, and efficiency, all of which serve to dramatically reduce the unit cost of the fuel cell.

Pemion is environmentally friendlier than conventional fluorinated membrane and polymer technology, decreasing reliance on these increasingly regulated materials, and enables simplified and lower-cost recycling for the recovery of expensive catalysts at end of life.

Bill Haberlin, Chief Executive Officer of Ionomr said, “Governments and regulators across Europe, in the U.S., indeed, around the world, are rightly calling for the elimination of toxic, perfluorinated materials. Pemion is an ideal replacement for conventional materials, for its environmental benefits and for its superior performance. With our Pemion materials now produced at scale, our partners can take their fuel cell and other clean energy technologies to market faster, cleaner, and with better performance. Pemion provides a tangible differentiation in the heavy-duty market.”

Dr. Matthias Breitwieser, Chief Technology Officer at ionysis GmbH said, “We have been collaborating with Ionomr for several years, and after working with their Pemion materials have now achieved a step change in the performance of fully hydrocarbon membrane-electrode-assemblies (MEAs), rivaling PFSA solutions. Based on this success, we've established our new company, ionysis, to develop high performance hydrocarbon MEAs as a viable alternative to conventional solutions."

Pemion represents a fundamental shift in proton exchange technology. Conventional polymers and membranes are produced using perfluorinated sulfonic acid chemistry. Perfluorinated compounds are known environmental toxins that can leach into water sources, accumulate biologically in living organisms and are difficult to recycle.

Eliminating these widely used substances from all sources is an urgent focus globally. Pemion products are produced using environmentally benign hydrocarbon materials and avoid the environmental problems associated with conventional counterparts, while still achieving maximum durability and performance.

Also, significantly, Pemion materials’ gains in performance and reductions in gas crossover result in a significant reduction in lifetime H2 fuel cell cost. Higher temperatures are possible for higher power stacks with improved cooling and higher efficiency, and the lifetime of the fuel cell is enhanced due to reduced degradation. Pemion boasts one of the highest room temperature conductivities available while maintaining its mechanical stability for improved overall efficiency and longer system life.