News

Argonne National Laboratory develops cobalt-based catalyst for electrolyzers

A plentiful supply of clean energy is lurking in plain sight. It is the H2 we can extract from water (H2O) using renewable energy. Scientists are seeking low-cost methods for producing clean H2 from water to replace fossil fuels, as part of the quest to combat climate change.

H2 can power vehicles while emitting nothing but water. H2 is also an important chemical for many industrial processes, most notably in steel making and ammonia production. Using cleaner H2 is highly desirable in those industries.

A multi-institutional team led by the U.S. Department of Energy’s (DOE) Argonne National Laboratory has developed a low-cost catalyst for a process that yields clean H2 from water. Other contributors include DOE’s Sandia National Laboratories and Lawrence Berkeley National Laboratory, as well as Giner Inc.

“A process called electrolysis produces H2 and oxygen from water and has been around for more than a century,” said Di-Jia Liu, senior chemist at Argonne. He also holds a joint appointment in the Pritzker School of Molecular Engineering at the University of Chicago.

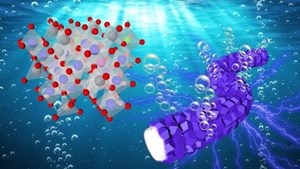

Proton exchange membrane (PEM) electrolyzers represent a new generation of technology for this process. They can split water into H2 and oxygen with higher efficiency at near room temperature. The reduced energy demand makes them an ideal choice for producing clean H2 by using renewable but intermittent sources, such as solar and wind.

This electrolyzer runs with separate catalysts for each of its electrodes (cathode and anode). The cathode catalyst yields H2, while the anode catalyst forms oxygen. A problem is that the anode catalyst uses iridium, which has a current market price of around $5,000 per ounce. The lack of supply and high cost of iridium pose a major barrier for widespread adoption of PEM electrolyzers.

The main ingredient in the new catalyst is cobalt, which is substantially cheaper than iridium. “We sought to develop a low-cost anode catalyst in a PEM electrolyzer that generates H2 at high throughput while consuming minimal energy,” Liu said. “By using the cobalt-based catalyst prepared by our method, one could remove the main bottleneck of cost to producing clean H2 in an electrolyzer.”

Giner Inc., a leading research and development company working toward commercialization of electrolyzers and fuel cells, evaluated the new catalyst using its PEM electrolyzer test stations under industrial operating conditions. The performance and durability far exceeded that of competitors’ catalysts.

Important to further advancing the catalyst performance is understanding the reaction mechanism at the atomic scale under electrolyzer operating conditions. The team deciphered critical structural changes that occur in the catalyst under operating conditions by using X-ray analyses at the Advanced Photon Source (APS) at Argonne. They also identified key catalyst features using electron microscopy at Sandia Labs and at Argonne’s Center for Nanoscale Materials (CNM). The APS and CNM are both DOE Office of Science user facilities.

“We imaged the atomic structure on the surface of the new catalyst at various stages of preparation,” said Jianguo Wen, an Argonne materials scientist.

In addition, computational modeling at Berkeley Lab revealed important insights into the catalyst’s durability under reaction conditions. The team’s achievement is a step forward in DOE’s H2 Energy Earthshot initiative, which mimics the U.S. space program’s Moon Shot of the 1960s. Its ambitious goal is to lower the cost for green H2 production to $1/kg in a decade. Production of green H2 at that cost could reshape the nation’s economy. Applications include the electric grid, manufacturing, transportation and residential and commercial heating.

“More generally, our results establish a promising path forward in replacing catalysts made from expensive precious metals with elements that are much less expensive and more abundant,” Liu noted.