News

Cell Impact enables precise measurements in flow plate production for fuel cells

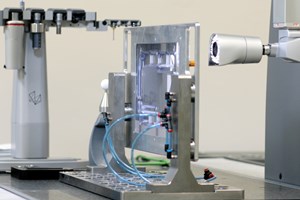

Flow plates for fuel cells are created by forming very thin sheets of metal with high velocity, in a single stroke, to create complex patterns. Extreme precision is required for the finished flow plate to work. With this new measuring technology, there is unique capacity to measure up to one-twentieth of a single strand of hair.

To secure the best possible conditions, the measuring facility is built as a separate entity within the factory in Karlskoga. The slightest vibrations affect the measurement result—as do changes in temperature. Therefore, there is no contact between the room and external walls and the temperature is kept at 20°C around the clock, with a permissible variation of 0.4°C. The measuring equipment is used to measure flow plates, forming tools and fixtures.

“As far as we know, these are unique measuring instruments. Separate instruments and sensors are found elsewhere, but nowhere are they combined in the same equipment. The latest unit we installed has a starting error of 0.28 my, which means we can measure details down to one-twentieth of a single strand of hair,” said Jonas Tausis, Senior metrology engineer.

The investment in new measurement technology is part of Phase II, Cell Impact's strategy to develop its offering and productivity, which aims to better satisfy the customers’ development objectives.

The instruments include Hexagon Global Blue 7.10.7, Hexagon Global Blue 12.22.10 and Leitz PMM Gold 7.7.5, and gives Cell Impact better opportunities to measure complex geometries quickly, accurately and continuously.

“This means that we can help the customer with their product development by linking the reliable measurement results of the geometric properties of the flow plate with the actual efficiency of the fuel cells. This helps us and the customers to take a clear, world-leading position in the H2 industry,” said Daniel Vallin, Chief Operating Officer.