News

New CSIRO company pursues hydrogen game changer for heavy industry

Australia’s national science agency, CSIRO, and corporate advisor RFC Ambrian have co-founded Hadean Energy, a new company to commercialize cutting-edge technology that can produce H2 with 30% less electricity and help to decarbonize heavy industry. CSIRO will trial the technology at BlueScope’s Port Kembla Steelworks to demonstrate the equipment at pilot scale in an industrial environment.

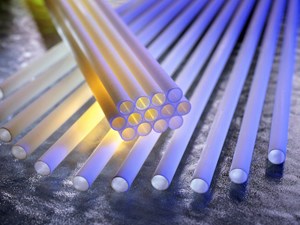

CSIRO’s tubular solid oxide electrolysis (SOE) technology efficiently produces H2 by electrolyzing water using a combination of heat and electricity and promises to significantly reduce H2 production costs and industry emissions through process efficiencies.

The International Energy Agency estimates that demand for H2 is expected to increase 138% by 2030, but high production costs and energy inputs are key challenges for producing green H2.

“The development of tubular SOE technology at CSIRO is a key project aimed at producing more affordable and efficient H2 to help industry dramatically reduce emissions,” said Sarb Giddey, lead scientist on H2 research at CSIRO.

“CSIRO’s SOE technology has the potential to produce H2 at a higher efficiency and lower cost for integration with industrial processes. It allows industrial waste heat to be integrated back into the industrial processes, which decreases the electrical energy required to produce H2 or syngas by up to 30%.”

“It’s great news for industry, because integrating the H2 product back into industrial processes onsite also eliminates storage and transport costs while drastically reducing the use of fossil fuels in the industrial process,” Giddey said.

The H2 product can be used as a feedstock for producing chemicals including ammonia, petrochemical, methanol, dimethyl ether, sustainable fuels and has applications in low-emission steelmaking and heavy transport. Being free of platinum group metals and nickel also reduces reliance on international supply chains. Hadean Energy will have exclusive rights over CSIRO’s SOE technology.

The trial with BlueScope will commence in April 2024. Integration aspects and other findings from the trial will help to demonstrate the technology at a higher scale and confirm the technical robustness of the equipment.

“BlueScope supports the trial project as it aligns with their sustainability objectives,” said Chief Executive Australian Steel Products, Tania Archibald. “SOE has the potential to dramatically reduce the cost of H2 for low emissions steelmaking. The improved efficiency of SOE systems reduces energy consumption and reduces the electrical infrastructure required by electrolyzers.”

RFC Ambrian manages a decarbonization technology fund targeting early-stage investments in emerging technologies with the potential to decarbonize high-emissions industries.

“The technology is well placed to address the existing industrial H2 market which is currently almost 100% derived from fossil fuels,” said Stefan Skorut, RFC Ambrian’s CIO. “While SOE is the most efficient method of electrolysis, green H2 and synthetic fuels will remain uneconomic unless we address the scalability and cost of electrolyzers. CSIRO’s tubular SOE technology represents a step change improvement across these metrics.”