News

Atco Mining announces large-scale H2 storage estimates at Flat Bay project

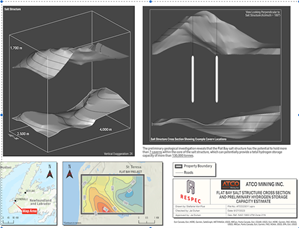

Atco Mining has completed a H2 storage capacity assessment for its salt structure at the Flat Bay Salt Project. The work was completed by the company's contracted consultant partner, RESPEC Consulting, who has direct experience in underground H2 storage caverns.

Based on the interpreted geology, operating pressure limits set by the Canadian Standards Association (CSA), and cavern dimensions, RESPEC generated preliminary cavern layouts and performed high-level thermodynamic calculations to estimate the maximum H2 storage capacity of the salt structure at the Flat Bay project site.

The cavern field layout depends on the areal extent and thickness of the salt structure. The cavern layouts generated for the Flat Bay project site salt structure are based on the following preliminary design considerations: (1) caverns are placed at an S/D ratio of 4 (where S is the distance between the center of one cavern to another cavern and D is the average maximum diameter of the two caverns), (2) caverns are at least a 1.5 cavern diameter length away from the salt dome boundary, (3) cavern diameter is limited to 80 m, (4) the cavern roof is located at least 200 m below the top of salt and (5) caverns bottoms are at least 200 m away from the bottom of salt.

Because the 2D seismic interpretation results decrease in accuracy with increased distance from the seismic lines, RESPEC generated conservative and optimistic cavern field layouts based on the distance from the seismic lines and distance from the core of the salt structure. The conservative case only considers salt caverns closer to the seismic lines and within the salt structure core. Whereas the optimistic case also includes caverns away from the core of the salt structure.

Based on the available geological information, the Flat Bay salt structure can potentially hold approximately:

- 7 caverns providing a total H2 storage capacity of 130,000 tons for the conservative case

- 14 caverns providing a total H2 storage capacity of 250,000 tons for the optimistic case.

It is important to note that this cavern layout is preliminary and heavily based on the gravity and 2D seismic interpretation of the salt structure, which may change as additional geologic data are obtained. RESPEC anticipates that the preliminary cavern field layout and H2 storage capacity estimates will need to be updated as potential core wells are drilled, and more 3D seismic surveys are performed.

Jai Duhan, Subsurface Energy Storage Consultant at RESPEC, said, “Based on the available geological information, the Flat Bay project site can potentially hold multiple caverns providing more than 130,000 tons of H2 storage. The next steps for Atco Mining would be to drill exploratory core wells and run additional seismic surveys to confirm the depth and thickness of the salt structure. RESPEC is looking forward to continuing to assist Atco in further defining the dimensions of the salt structure and obtaining rock parameters required for determining the quality of salt.”

Etienne Moshevich, CEO of Atco Mining, said, “This is a tremendous milestone to achieve with RESPEC. Being able to now have the necessary preliminary data to see how much H2 we can potentially store in our salt caverns is extremely important as we look to expand and build our company. If these results are accurate, Atco’s Flat Bay Salt Project has the potential to not only store significant amounts of H2 but also capitalize on the tremendous amount of investment that is ear-marked to be spent in the area building renewable energy projects. Our goal is to position Atco as a leader in the H2 storage industry and these results bring us one step closer towards achieving just that.”