News

INNIO’s Jenbacher H2-ready technology will empower Danone’s South Africa power plant

INNIO Group (INNIO*) has announced that Danone SA will install Jenbacher* technology at its existing power plant in Anderbolt, Boksburg, South Africa. This will empower Danone to integrate a wide selection of distributed energy resources (DERs), such as renewables and storage devices, while ensuring business continuity through energy resilience and plant uptime. The instability of the grid, the ambition to reduce carbon emissions and the proposed return on investment motivated Danone to drive energy efficiency with combined heat and power technology while producing distributed power and heat for their industrial process.

“Our Jenbacher microgrid solution empowers Danone to become independent from the electricity grid supply,” said Dr. Olaf Berlien, President and CEO of INNIO Group. “Their investment in our ‘Ready for H2’ technology will drive site energy efficiency and empower their pathway to net zero.”

INNIO’s energy solution will support Danone to keep power up during grid instability. The Jenbacher engines are operating on natural gas as a transitional energy source and can be converted to H2 as soon as sufficient H2 is available. In addition, the combined heat and power solutions will increase total efficiency and reduce costs and CO2 emissions.

“Jenbacher energy solutions are an excellent fit for our 2050 net-zero carbon commitment, a key performance indicator under the Danone Impact Journey, ensuring business continuity through energy resilience,” said Kid Nkantsu, Senior Director for Operations and Design to Deliver at Danone Sub-Saharan Africa. “With our frequent power supply outages, this microgrid solution will allow us to become independent from the grid, increase production uptime and integrate various distributed energy resources including hydrogen all while reducing our carbon footprint.”

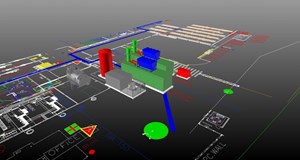

Clarke Energy, an authorized distributor for INNIO’s Jenbacher engines, will deliver the engineering, procurement and construction of the new microgrid facility, which will utilize two Jenbacher J616 containerized engines and the Jenbacher microgrid controller, providing a total capacity of 5 MWe.

Due to insufficient power-generation capacity, there is significant interest in decentralized combined heat and power (CHP) engine plants. CHP engine plants deliver power producers a low cost of operation, low emissions and high availability.