News

Tech breakthrough makes $2.5-T H2 boom possible

The U.S. government announced a proposed $7 B (for starters) on desperately needed breakthroughs in clean H2 production. The U.S. Department of Energy’s (DOE) biggest bet is on nuclear power plants, which they are hoping to convert into North America’s premier clean H2 producers.

Those billions of dollars are being poured into technological innovation, lowering costs and scaling up the production of clean H2, including through the use of nuclear power plants in New York, Ohio, Minnesota and Arizona.

For now, the majority of H2 in the U.S. is produced by natural gas reforming in large central plants—an important step in the energy transition. However, the end goal is to produce H2 without creating carbon emissions, and that’s what the federal government’s $7-B spend is all about.

At four nuclear plants across the country, scientists are trying to perfect a process called electrolysis to create pure, clean H2. The process involves splitting water into pure H2 and oxygen using high temperature electrolyzers. For now, however, the process is prohibitively expensive and energy intensive.

GH Power has developed a unique renewable energy technology that uses exothermic reactions to create three highly sought-after green outputs: H2, alumina (aluminum oxide) and exothermic heat, killing three birds with one high-tech stone.

The H2 produced by the modular version of GH Power’s 2-MW reactor is pure and clean, with zero emissions, zero carbon and zero waste, using only 2 inputs (recycled aluminum and water).

GH Power has been developing the new type of reaction for H2 production over the past 7 years, and now it’s gearing up to flip the switch on the first commercial reactor of its kind in Hamilton Ontario, Canada.

Flipping the switch on this new reactor comes at a critical juncture in the global energy transition. The H2 Council estimates that H2 will represent 18% of all energy delivered to end users by 2050, avoiding 6 gigatons of carbon emissions annually and turning around an approximated $2.5 T in annual sales (not to mention creating 30-MM jobs globally).

GH Power’s reactor is self-sustaining, zero emission and is a net producer of energy for consumption. It’s 100% clean and modular, which means it can be assembled onsite to power North America’s industries for the first time with clean energy and cost competitive with conventional fossil fuels.

It also produces green H2, exothermic heat, as well as highly valuable green alumina, which has numerous commercial applications used for everything from lithium-ion batteries and LED lighting to semiconductor production. GH Power is planning to develop a plant which produces 11,700 tpy of green H2 to fuel 30-MW combined cycle plant with a net output of 27 MW.

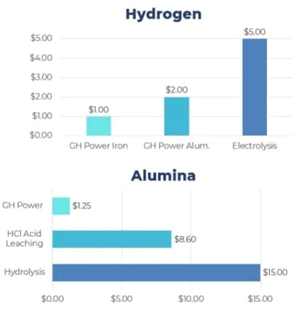

For now, the DoE puts the cost of producing H2 from renewable energy at about $5/kg, which is about 3X higher than the price of producing H2 from natural gas. The DOE’s goal is to see clean H2 production costs decline by 80% to $1/kg in a decade.

By the company’s estimates, GH Power’s reactor is already 60% cheaper than producing H2 by electrolysis, and it is a net producer of electricity to the grid. Its green alumina co-product production costs are also over 85% cheaper than the most commonly used processes currently used for alumina production that rely on hydrochloric acid leaching and hydrolysis for alumina production. This could be a game changer in the decarbonization of the critical sector.

Finally, GH Power’s base 27-MW net output plant design is forecast to produce a carbon offset of 1.2 MMtpy (based on displacing a coal-fired plant the same size). The company has also had successful tests using scrap steel (iron) as another metal fuel for H2 generation. The use of recycled metals provides a scalable solution with a much lower costs basis at under a $1/kg H2. Scrap iron is the most widely available metal fuel in most markets.