News

Vallourec New Energies strategy provides lift-off for H2 storage projects

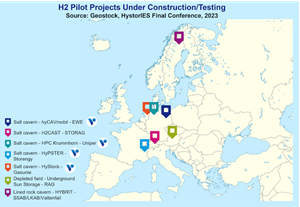

As the world embarks on a transition from fossil fuels to renewable energy, H2 has emerged as a crucial component of the clean energy mix. H2 storage is a pivotal component of a stable and reliable energy supply and will rely especially on vast underground caverns. On the European landscape, Vallourec is playing a major role in almost every salt cavern H2 storage project as part of its Vallourec New Energies strategy.

The rise of H2 energy is fueled by its diverse applications across various sectors, making it a pivotal player in the global pursuit of decarbonization. Serving as a versatile solution when finding utility in industrial processes, transportation and energy storage, H2 presents unparalleled potential to reshape the energy landscape.

“More than 50 countries are now implementing H2 strategies; this is a great indicator of the global importance of H2. We estimate that the global H2 market today is around €150 B, and that’s going to rise significantly in the near term,” said Vincent Designolle, H2 Director at Vallourec New Energies.

Despite this positive outlook, the current challenge lies in the fact that less than 5% of today’s H2 can be considered clean and low-carbon. “One of the low-hanging fruits in this battle is replacing gray H2 with green or low-carbon alternatives,” said Vincent. “It’s an area that our teams at Vallourec have focused our attention on.”

As H2 energy is increasingly produced cleanly, the question arises: where to store it all? “H2 storage is of the utmost importance,” said Vincent. “When you look at natural gas, already 10-15% goes through underground facilities. It could be even more with H2, considering variabilities in production by electrolysis, but even taking lower assumptions imply very large storage needs. This is where we come in.”

With numerous projects now emerging to meet the rise of H2, the development of storage solutions for salt caverns, as well as the mastery of technical challenges, is crucial.

“H2 storage poses unique challenges these are primarily related to leakage risks and material compatibility. Given the element's small molecular size, H2 is more prone to leaking compared to other gases,” said Justine Bernard, H2 Storage Technical Manager for Vallourec.

Another complexity is that steel, commonly used in traditional energy applications, can be susceptible to embrittlement when in contact with H2.

To overcome these challenges, Vallourec leverages both its deep expertise in metallurgy and its rigorous R&D testing of steel grades to withstand exposure to the element. The result: the validation of specialized materials and connections tailored explicitly for H2 environments.

Storengy partnership: Collaborating with Storengy, Vallourec delivered its VM80S tubular solutions along with VAM 21 premium connections for the production string (conveying H2 between the cavern and the surface) of HyPSTER project, the first-ever H2 storage project supported by the EU. After the pipes were installed earlier this year, the project will soon be in operation to showcase first-class green H2 storage salt caverns situated in Etrez, France.

HyCAVmobil project: EWE’s HyCAVmobil project is intended to be the first practical implementation of a H2 cavern test in Germany, with aim to evaluate H2 quality after storage as well as technical and ecological aspects of the integration of a H2 cavern in the future energy system. The construction of the test cavern was finalized earlier this year. After ongoing construction of all surface facilities, first fill with H2 and testing plan are expected to start soon. The first step in the construction of the cavity involved EWE erecting a drilling rig on top of the existing borehole for which Vallourec supplied the casing, after which EWE flushed out the salt dome 1,000 meters underground with water.

Gasunie HyStock project: Last year, Vallourec successfully delivered and installed VM80S pipes and VAM 21 premium connections for a test borehole in the northern Netherlands. The nine-month project involved cycling H2 gas at different pressures to showcase the reality of Vallourec’s steel grades and VAM 21 connections in real-world conditions, confirming with solid field record great performance of materials and connections. Now, Vallourec’s R&D teams are performing tests on the pipes to gain more knowledge on long-term effects.

Uniper H2 pilot cavern project: Due to begin later this year, Vallourec is set to supply pipes in its weldable grade VM80W, some of which incorporate VAM 21 premium connections. The project is taking place in Krummhorn, Germany in the Ems estuary of the North Sea. The aim is to test the construction and operation of a 100% H2 storage facility, with the ultimate goal of developing a storage solution for green H2 on a commercial scale.

To fortify its commitment, the group unveiled Vallourec New Energies, a new strategic outlook and roadmap to best support collaboration across all renewable energy projects. This strategy fosters the development of Vallourec’s cutting-edge solutions for H2, carbon capture and geothermal energy, while streamlining the tender process for prospective renewable energy ventures. H2 storage thus plays a major role in Vallourec’s strategy for the future of the energy transition.