News

AGC high performance materials aid the expanding H2 market

The popularity of H2 as a cleaner fuel alternative is on the rise. It plays a crucial role in refining petroleum to reduce sulfur content and in creating zero-carbon fertilizers and fuels via ammonia production; additionally, H2 powers fuel cells.

Each year the U.S. generates about 10 MM metric t of H2. AGC Chemicals Americas provides fluoropolymer compounds essential for various stages of H2 production, storage and transport applications. For example, the FORBLUE brand of membranes and dispersions helps increase the process efficiency of H2 manufacturing and boost the performance of fuel cells.

In addition, the company offers specialty materials such as Fluon ETFE and PTFE resins, which are used for tanks and pipelines that store and transport H2. Fluon ETFE film has non-stick properties that allow it to be used as an effective carrier release film used in the catalytic membrane manufacturing process. Below is an overview of some of the uses of AGC products in the H2 market.

H2 manufacturing. According to the U.S. Department of Energy (DOE), H2 can be derived through various methods including direct solar water splitting, thermochemical processes, electrolytic processes and biological processes.

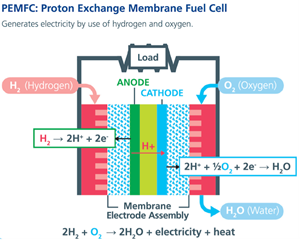

Among these, proton exchange membrane (PEM) water electrolysis stands out as the premier method for generating high-quality, carbon-free H2. This thermochemical method is on the rise, especially as global efforts concentrate on reducing carbon emissions and shifting towards alternatives like green H2.

In this method, the anodic reactions oxidize and dissolve metals, while the cathodic reactions reduce dissolved oxygen, leading to the formation of hydroxyl ions. For optimal efficiency in the production of H2, it’s essential to keep the anodic and cathodic chambers separate.

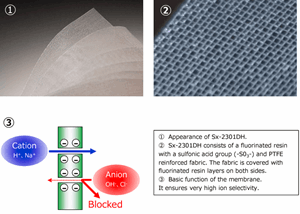

- AGC’s FORBLUE S-Series membranes are designed for ion exchange separation in H2 They selectively filter protons, moving them from the anode to the cathode chamber. Created from fluorinated resins, these membranes can endure both the acid on the anodic side and the base on the cathodic side. With the added reinforcement of a special PTFE fabric, they provide enhanced strength, ensuring high ion selectivity and cation permeability. These membranes come in various grades, each with ion exchange capacities ranging from 1.0 meq/g–1.25 meq/g.

- Anion exchange membrane (AEM) water electrolysis is a more affordable production method, though it typically yields H2 of lower purity. FORBLUE Selemion hydrocarbon-type ion exchange membranes are used as AEM separators, similar to how the S-Series is used in PEM processes. These membranes come in different polymers and thicknesses, ensuring high selectivity with minimal proton leakage.

- In fuel cell manufacturing, FORBLUE I-Series Ionomer Dispersions boost the electrode performance of H2 fuel cell electrodes. When integrated into the fuel cell’s electrolyte membranes and electrodes, this polymer increases proton flow and ensures chemical stability. As a result, vehicles powered by these fuel cells have greater energy output and more dependable long-term performance.

H2 storage. H2 can be stored in two forms: as a compressed gas or as a liquid. Compressed H2 is kept in high-pressure tanks, while liquid H2 requires tanks that can handle cryogenic temperatures.

- LUMIFLON was developed by AGC as a weather-resistant exterior coating for tanks that store liquid H2. It is curable at a wide temperature range and offers good chemical stability with excellent weatherability compared to other topcoats.

- Fluon ETFE high-performance fluoropolymers are used to line hoses and pumps used in H2 This tough fluoropolymer offers higher chemical resistance and electrical properties than typical fluoropolymers. When used as an inner layer lining, Fluon ETFE is stable against most chemicals and has high- to low-temperature fluctuations.

H2 transport. H2 is transported to plants, industrial facilities, and fueling stations through an infrastructure that may contain pipelines, trucks, storage facilities, and dispensers. AGC materials are used in a variety of these assets serving different roles:

- AFLAS Fluoroelastomers serve as sealing materials in H2 valves and H2 They offer excellent chemical resistance and durability under high-temperature and high-pressure conditions. The fluoroelastomers are easily compounded into finished parts and shapes such as rubber seals.

- Fluon PTFE high-performance fluoropolymers are used to line pipelines that transport H2 in addition to hoses and pumps used in H2 storage as previously described.

Advancing green energy. The H2 Energy Application Lab at AGC Chemicals Europe is equipped for both in-situ and ex-situ testing of PEM and water electrolysis. This allows for comprehensive analysis within the H2 sector. The facility plays an important role in pioneering membrane solutions that assist industries in moving towards a zero-emission future.