News

Chung-Ang University researchers develop a low-cost catalyst for green H2 production

Sustainable electrolysis for green H2 production is challenging, primarily due to the absence of efficient, low-cost and stable catalysts for the oxygen evolution reaction in acidic solutions. A team of researchers has now developed a ruthenium catalyst by doping it with zinc, resulting in enhanced stability and reactivity compared to its commercial version. The proposed strategy can revolutionize H2 production by paving the way for next generation electrocatalysts that contribute to clean energy technologies.

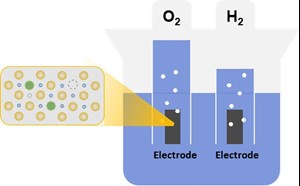

Electrolysis is a process that uses electricity to create H2 and oxygen molecules from water. The use of proton exchange membrane (PEM) and renewable energy for water electrolysis is widely regarded as a sustainable method for H2 production. However, a challenge in advancing PEM water electrolysis technology is the lack of efficient, low-cost and stable catalysts for oxygen evolution reaction (OER) in acidic solutions during PEM water electrolysis. While iridium-based catalysts are a potential solution, metallic iridium is rare and expensive in nature. Alternately, oxides of ruthenium (RuO2) offer a more affordable and reactive option, but they also suffer from stability issues. Therefore, researchers are exploring ways to improve the stability of the RuO2 structure to develop promising OER catalysts for the successful implementation of the H2 production technology.

Now, in a recent study, a group of researchers, led by Professor Haeseong Jang from the Department of Advanced Materials Engineering at Chung-Ang University, has developed a promising OER catalyst. Denoted as SA Zn-RuO2, the catalyst comprises of RuO2 stabilized by single atoms of zinc. Elaborating about their study, Prof. Jang said, “We were motivated by the need to find efficient and cost-effective alternative electrocatalysts for OER in PEM water electrolysis. Based on our study, we propose a dual-engineering strategy, involving single atom Zn doping and the introduction of oxygen vacancies, to balance high catalytic activity with stability during acidic OER.”

The researchers synthesized SA Zn-RuO2 by heating an organic framework with ruthenium (Ru) and zinc atoms, forming a structure with oxygen vacancies (missing oxygen atoms that positively alter the properties) and Zn-O-Ru linkages. These linkages stabilize the catalyst in two ways—one, by strengthening the Ru-O bonds, and second, by providing electrons from zinc atoms to protect ruthenium from overoxidation during the OER process. Furthermore, the improved electronic environment around the ruthenium atoms lowers the energies needed for molecules to stick to the surface, thus lowering the energy barrier for the reaction.

The resulting catalyst was more stable, with no apparent fall in reactivity, and significantly outperformed commercial RuO2. Moreover, it required less extra energy (low overpotential of 213 mV compared to 270 mV for commercial RuO2) and remained functional for a longer period (43 hours compared to 7.4 hours for commercial RuO2).

Due to its improved stability and features, the newly proposed SA Zn-RuO2 catalyst has the potential to influence the development of cost-effective, active, and acid-resistant electrocatalysts for OER. This, in turn, could help in reducing costs and enhancing the production of green H2, aiding in a shift toward cleaner energy sources and advancements in sustainable technologies.

“We believe that this shift can revolutionize industries, transportation and energy infrastructure, and contribute to the efforts aimed at combating climate change and fostering a more resilient and environmentally conscious future. This is because accessible green H2 can have a transformative impact on societies by mitigating environmental impacts, creating jobs, and ensuring energy security through diversified and sustainable energy solutions,” envisioned Prof. Jang.