News

Argonne plays critical role in consortium to advance fuel cell and electrolyzer manufacturing

Argonne is part of a multi-laboratory consortium working to advance manufacturing to make H2 fuel cells and electrolyzers more durable, efficient and affordable. Argonne will focus on scaling up fuel cells and electrolyzer catalysts.

With the goal of advancing clean H2 manufacturing technologies, the U.S. Department of Energy’s (DOE) Argonne National Laboratory will play an important role in a new consortium of DOE laboratories formed to accelerate production of fuel cells and electrolyzers (DOE National Laboratory Consortium to Advance High-Volume Manufacturing of Critical Clean H2 Technologies | Department of Energy).

The roll-to-roll (R2R) Consortium is funded by the H2 and Fuel Cell Technologies Office (HFTO) of DOE’s Office of Energy Efficiency and Renewable Energy, under two provisions in the Bipartisan Infrastructure Law: The Clean H2 Electrolysis Program and the Clean H2 Manufacturing and Recycling Program. The consortium will develop advanced coating and drying technologies and R2R manufacturing processes to make fuel cells and electrolyzers more durable, efficient and affordable.

Electrolyzers and fuel cells are critical to producing and utilizing zero-carbon green H2, which helps bring the U.S. closer to achieving its carbon reduction goals to slow climate change. The consortium’s goal is to de-risk and accelerate U.S. manufacturing of high-performance, low-cost fuel cells and electrolyzer systems to meet commercial-scale demand for H2 and boost industry adoption of clean H2 technologies.

The R2R Consortium is led by DOE’s National Renewable Energy Laboratory (NREL). Along with Argonne and the following DOE laboratories, the consortium includes Oak Ridge National Laboratory (ORNL), Lawrence Berkeley National Laboratory (LBNL) and Sandia National Laboratories (SNL). Each laboratory will focus on a few specific research areas and collaborate within the consortium to achieve overall goals.

“Through close collaboration with industry, the R2R Consortium will help solve current manufacturing challenges as well as develop next-generation manufacturing technologies that will accelerate the transfer of clean H2 technologies from the laboratory to industry,” said Yuepeng Zhang, an Argonne principal materials scientist.

Zhang and ORNL scientist Alexey Serov are deputy directors of the R2R Consortium. Scott Mauger, an NREL senior scientist, serves as the R2R Consortium director. This leadership team directs the consortium’s activities, facilitates collaborations with other HFTO consortia and assists HFTO’s strategic planning of the consortium’s research focus.

Electrolyzers and fuel cells are key to transitioning H2 into widespread use. Electrolyzers split water molecules to make H2. Fuel cells use H2 to cleanly and efficiently produce electricity for electric cars and other energy applications.

Compared to current methods for manufacturing electrolyzers and fuel cells, R2R manufacturing increases speed, improves efficiency, and cuts downtime and waste, slashing costs. R2R manufacturing deposits materials onto moving webs and is a scalable, continuous production process.

There are obstacles to overcome, however, to optimize multiple-step, multiple-variable processes during R2R manufacturing. The consortium will work to address these challenges by investigating and establishing comprehensive correlations between processing steps and parameters.

Both fuel cell and electrolysis technologies use catalysts to speed up chemical reactions. In the R2R Consortium, Argonne will lead catalyst materials synthesis scale-up. Scientists will leverage scale-up expertise and capabilities developed for lithium-ion battery materials synthesis scale-up in Argonne’s Materials Engineering Research Facility.

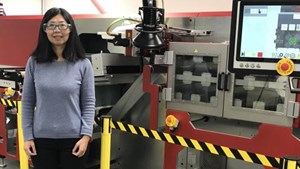

Jessica Durham Macholz, an Argonne principal materials scientist, will lead the consortium’s Materials Scale-up Science Thrust Area.

“Argonne and ORNL are working together to develop and de-risk scalable technologies to synthesize catalyst materials for fuel cells and electrolyzers. The goal of the research is to reliably produce large quantities of material faster, more cost effectively and with reduced environmental consequences. We hope to speed up the translation of new, high-performing materials produced by HFTO consortia to industry,” said Durham Macholz.

Collaboration among the laboratories is critical to success. Argonne will work with LBNL to characterize ink and coating by leveraging Argonne’s Advanced Photon Source (APS), one of the world’s premier storage-ring-based high-energy X-ray light source facilities. In addition, Argonne will work with NREL and SNL on ink formulation, coating and in-line metrology development. Argonne will support the consortium’s technoeconomic analysis by customizing its Innovative Manufacturing and Processing Assessment Calculating Tool. The APS is a DOE Office of Science user facility.

Argonne will also lead the ML development effort that utilizes artificial intelligence-assisted process optimization and automation to facilitate smart fuel cell and electrolyzer manufacturing. Argonne will work with the other national laboratories to achieve this goal.

The R2R consortium will support industry efforts through cooperative research and development agreement projects. An industrial advisory board will provide guidance on the consortium’s research objectives. The board will also foster engagement among manufacturers, materials suppliers and the H2 industry.

R2R activities will also complement the work of other HFTO consortia: H2 from Next-generation Electrolyzers of Water (H2NEW) and Million Mile Fuel Cell Truck (M2FCT). The R2R Consortium will develop processes and pathways to scale up materials and components developed by H2NEW and M2FCT and will work closely with both consortia to ensure relevant metrics, methods and protocols are used.

Together, these efforts will help advance DOE’s H2@Scale vision and the H2 Shot goal of reducing the cost of clean H2 to $1/kg by 2031.