News

LANXESS ion exchange resins applied in hydrogen production

LANXESS has developed special ion exchange resin grades within its Lewatit UltraPure range that can be used for water treatment in proton exchange membrane (PEM) electrolysis. This process, which converts electricity from preferably renewable energies into H2, is regarded as a promising approach to the sustainable production of this precious gas. In this way, fluctuations in wind power and solar radiation can be better compensated.

Experts believe that PEM electrolysis will play an important role in the transition to a H2-based economy. Compared to alkaline electrolysis, the high current density of PEM electrolysis allows H2 to be produced in smaller systems. Another advantage: H2 filling stations can be connected directly to the high-pressure outlet.

The process is now so well developed that it enables highly efficient production in the megawatt (MW) range. This requires continuous purification of the process water. LANXESS recommends its Lewatit UltraPure 1242 MD [strong base anion (SBA) exchange resin], Lewatit UltraPure 1212 MD [strong acidc cation (SAC) exchange resins] and Lewatit UltraPure 1295 MD ion exchange resins, which are optimized for this application, to ensure low total organic carbon (TOC) throw.

LANXESS’s liquid purification technologies (LPT) business unit is in talks with renowned gas producers to establish standards for efficient water treatment in PEM electrolysis plants. Hans-Juergen Wedemeyer, Technical Marketing Manager at LPT, explained, “Our technical expertise, combined with our high-performance ion exchange resins, support the water purification process for systems. Preliminary application test results enable the plant conditions to be simulated and the state-of-the-art Lewatit UltraPure ion exchange resins to be optimally used. LANXESS is thus supporting a sustainable, climate-friendly energy supply.”

In PEM electrolysis, a PEM electrolyzer is used to split water into the components H2 and oxygen (O2). If the electricity for this process is provided from renewable energies, this is accomplished with very low CO2 emissions. PEM technology employs several water circuits. In addition, fresh water is continuously introduced to compensate for the loss of water during the production of H2.

Demineralized water is used as process water, as the membrane would suffer from severe damage within a very short time due to minerals and other impurities. In 100-MW PEM systems, for example, around 6,000 m3−7,000 m3 of process water are circulated per hour and require adequate treatment.

Operating temperatures range between 50˚ C and 70°C during the process. This can release metallic and organic impurities from the system components. For stable hydrogene production and an economical service life of the PEM stack, it is essential to constantly reduce these impurities to a minimum. LANXESS has designed a special process water treatment with Lewatit UltraPure resins in combination with UV light.

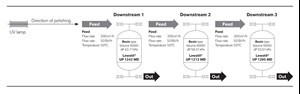

Ion exchangers continuously purify the water circuits. To stabilize the water cycle quality, a partial flow of around three to six percent of the total water volume is continuously purified in a polisher unit. LANXESS recommends an upstream UV lamp to oxidize the organic matter (TOC) followed by a combination of anion and cation exchange resins and a final polisher filter.