News

Pusan National University study provides breakthrough in enhancing solid oxide fuel cell efficiency

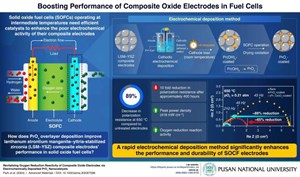

Improving the efficiency of solid oxide fuel cells (SOFCs) is crucial for advancing clean energy technologies. Researchers from Korea have developed a rapid, practical method to deposit a praseodymium oxide (PrOx) layer on lanthanum strontium manganite–yttria-stabilized zirconia (LSM–YSZ) composite electrodes. This PrOx coating significantly enhances oxygen reduction and boosts electrode performance, reducing polarization resistance by 89% and increasing reliability and efficiency in energy production.

Rising global demand for clean energy drives advancements in technologies like SOFCs, known for converting H2 and methane into emission-free electricity. SOFCs rely on key components: electrodes (cathode and anode) and the electrolyte, which are essential for converting chemical energy into electrical energy. These components are typically made from materials like lanthanum strontium manganite (LSM) and yttria-stabilized zirconia (YSZ). Combining LSM and YSZ to form LSM-YSZ enhances stability and durability, ensuring a prolonged electrode lifespan.

Current SOFC technology faces challenges, notably electrode degradation, exacerbated at lower temperatures. Enhancing the oxygen reduction reaction (ORR) at the cathode is crucial for improving ion flow and overall fuel cell performance and durability. Addressing these issues is vital for expanding SOFC applications in energy conversion systems.

To address current challenges, a team of researchers led by Professor Beom-Kyeong Park recently conducted a study aimed at enhancing the performance of LSM–YSZ electrodes in SOFCs. Their research, available online since March 22, 2024, and published in Volume 36 of the Journal of Advanced Materials on June 20, 2024, focused on improving LSM–YSZ electrodes using nanocatalysts such as praseodymium oxide (PrOx). These catalysts, known for their high surface area-to-volume ratios, were employed to enhance the efficiency of the ORR.

Using cathodic electrochemical deposition (CELD), the research team efficiently deposited PrOx nanocatalysts onto LSM-YSZ electrodes in less than four minutes without requiring heat treatment. Prof. Park highlighted the significance, stating, "We harness the outstanding catalytic properties of PrOx to notably enhance the ORR activity of LSM–YSZ electrodes. The CELD method provides a rapid and cost-effective solution, feasible under standard operating conditions."

The study demonstrated significant enhancements in SOFC electrode performance with PrOx coating, showing an 89% resistance reduction at high temperatures sustained over 400 hours. Achieving 418 mW cm−2 peak power density at 650°C surpassed other cathodes. Research also explored (Pr,Ce)Ox multicomponent coatings via electrochemical deposition, offering avenues for further optimization.

Prof. Park emphasizes the far-reaching implications of their research, stating, "By significantly enhancing electrode performance and durability, our method could pave the way for wider adoption of SOFCs in energy conversion and storage systems. This advancement holds immense promise for applications requiring reliable and sustainable power generation. It offers a pathway to mitigate greenhouse gas emissions and enhance global energy security."

This innovative approach to creating high-performance energy devices, including all-ceramic materials, presents a promising future for clean energy technology.