News

NETL-funded project holds potential for cleaner H2-based energy infrastructure

Tulsa, Oklahoma-based ClearSign Technologies Corporation was awarded $1.65 MM in Phase II Small Business Innovation Research (SBIR) funding for the development of its “Flexible Fuel Ultra-Low Nitrogen Oxide (NOx) Process Burner,” technology that can foster decarbonized H2 power use across the country in industrial settings.

A significant strategy toward decarbonizing the nation’s economy and power sector is the increased use of H2 sourced from America’s abundant energy resources when combined with new carbon capture technologies. H2 fuel can be converted to electricity with already available technologies such as gas turbines and fuel cells. Yet, most industrial processes still require a low-cost source of heating fuel to operate. At present, industrial burners fulfill this requirement by efficiently converting hydrocarbon fuels to heat within a furnace or boiler.

NOx produced during the combustion process contributes to the formation of photochemical smog, ozone, and acid rain causing harm to humans and ecosystems. With stricter regulations of NOx emissions, engineers have been further challenged to develop improved burner designs for mitigating emissions while still achieving all other requirements.

Most currently installed burners have increased NOx emissions when using H2 as a fuel or may fail to operate altogether. To decarbonize industrial heating, the development of an industrial H2 burner technology is needed, and burning H2 for industrial processes requires new burner technology to operate safely while also controlling NOx emissions.

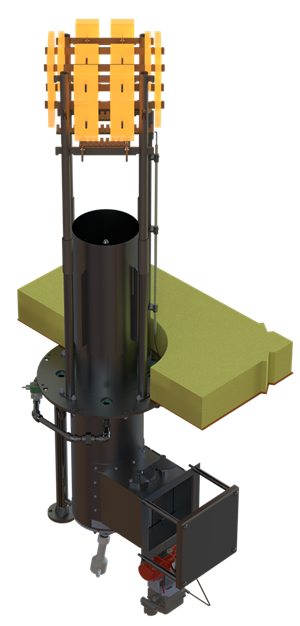

ClearSign’s current burner technology, branded ClearSign Core, reduces emissions to the order of those achieved by more complicated and costly aftertreatment systems and does so without the use of expensive catalysts or chemicals. The technology controls flame chemistry and optimizes flame structure to provide extremely low NOx emissions.

“ClearSign’s burner technology has already been successfully applied to refinery process heaters, boilers and enclosed combustors,” said Drew O’Connell, Federal Project Manager with NETL’s H2 with Carbon Management Team. “Running completely on H2, the updated burner can achieve very low NOx emissions, consistently below 5 parts per million. This helps companies meet strict environmental regulations while providing cost savings.”

ClearSign is seeking and considering various potential early adopters of the ClearSign fuel-flexible H2 burner. A typical application would be one with upfired, natural draft process heaters, with the refinery fuel gas having high concentrations of H2 up to 100% and requiring emissions compliance of ultra-low levels of NOx. Such host sites will provide early feedback and a reference in the marketplace, thus assisting in the rapid commercialization, adoption and use in the marketplace.

Widespread adoption of the ClearSign fuel-flexible H2 burner by 2034 could offset approximately 70 MMt of carbon dioxide (CO2) and reduce NOx emissions by 21,000 tpy. This approach to decarbonization is economical and non-disruptive, facilitating industry adoption. With global CO2 emissions from refineries nearing a Btpy, it is estimated that by 2029, a reduction of 3.5 MMtpy could be achieved using this method.

This award through NETL highlights the unique ability of the U.S. Department of Energy’s SBIR program to enable small businesses to explore their technological potential, leading to the development and commercialization of innovative clean energy solutions. By including qualified small businesses in the nation's research and development (R&D) arena, high-tech innovation is stimulated, and federal R&D needs can be met.