News

Online Feature: Green hydrogen: A critical balancing act─Part 2

Author: Mika Kulju, President, Danfoss Drives

Part 1 of this article touches on green H2 for decarbonizing hard-to-abate sectors and stabilizing renewable energy grids, despite the challenges of production demands. As global leaders commit to moving away from fossil fuels, efficiently scaling up H2 production while managing its costs and energy requirements is essential. The article was the first in a series exploring how green H2 can be integrated into the green transition effectively, emphasizing the need for advanced technologies and strategic planning.

H2 production will have a massive pull on the electricity grid in the future. As such, we must make sure to produce H2 as efficiently as possible and to avoid unnecessary disturbances in the grid. Green H2 is produced by an electrolyzer that splits water into oxygen and H2 using electricity. All electrolyzers use direct current (DC), while the electricity grid is powered by alternating current (AC). DC is found in regular AAA batteries, and the current always flows in one direction, whereas the AC in the grid periodically changes direction. This means that there is a need to convert the electricity from AC to DC to produce H2. A low-quality AC/DC converter will disturb the AC on the grid, and costly compensation equipment will be needed to restore power quality.

Such disturbances in the grid from inefficient converters are a growing concern when discussing H2 production. Similarly, inefficient converters will deliver a low-quality DC to the electrolysis plant. However, there are already better converters on the market now. These create next-to-no disturbance in the grid, rendering compensation equipment obsolete, while delivering cleaner DC supply to the electrolysis plant. The cleaner DC supply can increase the overall efficiency of the production by roughly 1%.32 And while this may not sound like much, 1% of the future electricity demand for H2 is actually enough to power London for almost four years.33 Additionally, some of the cost of higher-quality converters can be balanced out by the reduced need for compensation equipment and the maintenance that follows. Sometimes better equipment can simplify a system and also improve grid resilience.

Flexible H2 saves emissions and money. Efficient H2 production is not just about how we produce it, but also when we produce it. Let’s imagine a future where we produce H2 when renewable electricity is plentiful, so we can deliver energy back to the grid when it is scarce. This is far from a sci-fi scenario: the solutions to use H2 production as a lever for creating a more flexible energy system already exist and are ready to be implemented today.

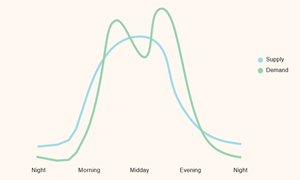

The way we use energy throughout the course of a day is dictated by our behavior as humans. In the hours of the very early morning, most of us are fast asleep. However, as we wake up to start our day, water flows to buildings, gas to stoves and electricity to homes. After a midday dip in energy demand, school and work finally let out and families return home. This is when we become hungry for energy. Dinners are prepared, laundry is washed, movies are watched, and lights switch on as day turns to night.

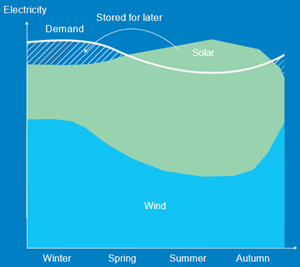

This is an example of how the energy demand cycles over the course of a normal weekday in a relatively developed energy grid. In a future energy system run on renewable energy sources; however, there will be peaks and valleys in the generation of energy as well (FIG. 2). The sharp peak in energy consumption that the grid experiences when people wake up or get home after a long day at work does not always align perfectly with periods of bright sunshine or intense winds.

This misalignment represents one of the major challenges of our future energy system. Currently, even in countries with a high share of renewables in the energy mix, fossil fuels are still used as residual energy sources in peak hours, meaning we release far more CO2 than necessary during these periods. Similarly, we pay renewable energy producers hundreds of millions per year to shut down production in periods with too much wind or sun.34 However, flexibility can reduce this curtailment by 25% already by 2030 and H2 production has a major role to play in this.35

In a world where we can neither fire up fossil fuel power plants to meet peaks in demand nor pay renewable energy producers to shut down production, we must find new ways to manage energy more flexibly. Aligning green H2 production with periods of excess renewable electricity is one of our best tools for achieving this.

We must produce H2 when renewable energy supply is higher than demand. On a daily basis, this represents the periods in the middle of the day when the sun is at its highest but when we consume a relatively low amount. To balance out the curve and to avoid curtailment, this excess renewable electricity can be directed towards electrolysis plants. Similarly, if electricity demand goes up more than predicted, electrolyzer plants can react with incredible speed and temporarily turn down or shut off their operations. Additionally, on a seasonal basis, we use more electricity during the winter, despite producing more renewables in the summer. We can, however, store unused renewable electricity generated during the summer months in the form of H2. This stockpile can then be converted back into electricity, should demand outstrip supply throughout the winter months.

However, because power-H2-power conversion has a total round-trip efficiency of 18%−42%, we should not use H2 as a standard fuel for electricity generation.36 The timing of when we produce H2 can indeed make or break our ability to rapidly scale it in a sustainable way that does not put unnecessary strain on renewable energy production.

Case: Energy system flexibility in the EU and UK. An analysis commissioned by the author’s company examines the potential of demand-side flexibility in the EU and UK wholesale energy market.37 It finds that an ambitious but realistic rollout will lead to substantial societal and environmental benefits, as well as lower energy bills for consumers. The real potential is possibly greater, as this analysis does not consider savings in investments in the distribution grid and the internal transmission grid, and possible revenues from selling ancillary services to the system operators.

In the analysis, H2 production proved to be the greatest lever towards a flexible and stable energy system in the EU and UK. When the supply of renewable electricity surpasses demand, both wasting essential resources and risking destabilizing the grid, H2 production can be turned on. This stores renewable electricity in the form of H2 and helps stabilize infrequencies in the grid.

During the very recent energy crisis, the UK earmarked €103 B for the energy crisis, and the EU countries earmarked €681 B.38 There is another solution to become more resilient towards energy crises: The entire EU and UK can roll out demand-side flexibility measures. This can greatly reduce the need for government subsidies at this scale, as well as save money at both a societal and consumer level. Across the EU and UK, the average consumer can save 7% on their electricity bill by 2030 and 10% by 2050.

Flexibility is also an important tool to phase out fossil fuels from our electricity generation. Already by 2030, the annual electricity generation from natural gas can be drastically reduced by 106 TWhr, or about one-fifth of the EU’s natural gas consumption for electricity generation in 2022.39 Similarly, the EU and UK can save 40 MMtpy of CO2 emissions by 2030, more than Denmark’s domestic climate footprint in 2021.40 Alongside this, the EU and UK can achieve annual societal cost savings of €10.5 B by 2030 and €15.5 B by 2050, and this includes a significant part of the establishment cost of demand-side flexibility. Part of these savings in 2050 comes from a 21% decrease in investments in power lines.

The analysis is based on leveraging demand side flexibility solutions in different scenarios and degrees of flexibility in the EU and UK. You can read more about demand-side flexibility in the author’s company’s report, “Energy Efficiency 2.0: Engineering the Future Energy System”.41

Just as there are daily peaks in electricity production, there are also seasonal variations. At higher latitudes, it is necessary to heat the homes during winter, while mid- to low-latitude countries will have a higher demand for cooling during summer. Similarly, for the higher latitudes, there will be a gap between producing more renewable electricity in the summer while having the greatest need for electricity during the winter.

To fill out this gap, we must look at long-term storage options. Due to cost and capacity depletion over time, batteries are an ineffective solution for this. H2 can prove a much better option for long-term storage since it can hold large amounts of energy with only a very little energy loss over time at a low cost per MWhr.

Energy can be stored as H2 by converting low-emissions electricity into H2. There are several viable ways to store H2 on a large scale, from salt caverns to tanks.42 This makes it ideal for seasonal energy balancing.43 In order to store H2 in salt caverns, they must be drained from salt water. While draining the caverns, we can take advantage of the high salt concentrations to generate electricity through a process called reverse osmosis. This can help to increase the efficiency of all the links related to H2.

Moreover, the current pipelines for natural gas can be converted to transport H2.44 This way it is possible to use excess low-emissions electricity at one place to supply another region far away with energy, essentially creating a H2 market similar to the current natural gas market. H2 storage has many potential uses but is not as efficient for short-term storage as other forms such as batteries.

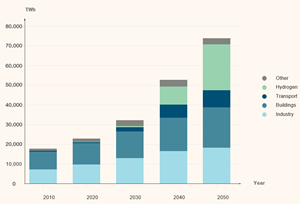

H2 can be an economic and sustainable choice for peak power periods, as very small volumes will be needed to serve these few peak hours a year.45,46 For now, it is expensive to store energy as H2, but the price is expected to decrease in the future with technological developments (FIG. 3).47,48

Leverage excess heat from H2 production. Renewable energy is not an inexhaustible resource. However, in a fully electrified energy system, the demand for renewable electricity will be enormous. Therefore, we must fully utilize all available energy sources across sectors, not least excess heat. Everywhere in our energy system, energy is wasted into the atmosphere as heat. This excess heat is a sleeping giant of energy efficiency; when strategically captured and deployed as energy, it has incredible potential to replace significant amounts of valuable energy sources such as fossil fuels and electricity, thereby saving both money and reducing GHG emissions.

Excess heat is most effective when planned through strategic sector integration. Sector integration is about combining different sectors to work together more efficiently and sustainably. Instead of treating each sector separately, sector integration aims to find ways to make them cooperate, reducing waste and improving overall system effectiveness. It also helps to reduce pressure on the energy grid by enabling greater exploitation of alternative energy sources such as excess heat.

Whether green, blue or gray, large-scale H2 production creates incredible amounts of excess heat. In this section, we explore regional and global emissions-saving potentials of excess heat both from H2 and other major sources.

Every time a machine runs, heat is generated. Just think of the warmth behind your fridge. The same is true on a larger scale with supermarkets, data centers, wastewater plants, metro stations and water electrolysis facilities found in cities across the globe. By 2030, up to 53% of the global energy input will be wasted as excess heat.49 Furthermore, the climate can benefit greatly if we recover excess heat. In fact, we can reduce global emissions by 10%−19% if we recover the full theoretical potential of excess heat.50

Heating is one of the largest energy consumers in the energy system. In Europe, heating accounts for more than 50% of the annual final energy consumption, and most European heat is still generated using fossil fuel-based sources, almost half of which is natural gas.51 Simultaneously, all urban areas in Europe have access to numerous excess heat resources. There are about 2,860 TWhr/yr of waste heat accessible in the EU, much of which could be reused.52 To put this number into perspective, it almost corresponds to the EU’s total energy demand for heat and hot water in residential and service sector buildings, which is approximately 3,180 TWhr/yr in the EU27+UK.53

In some countries, the excess heat potential even matches the total heat demand.54 In the Netherlands, for instance, excess heat amounts to 156 TWhr/yr, while the water and space heating demand is only 152 TWhr/yr.55,56 The picture is similar across the rest of the world as well. For instance, looking at the industrial sector in Northern China, there is around 813 TWhr of excess heat during heating season alone.57 Just imagine what the total amount of excess heat across all sectors in the whole of China looks like.

Just as we can use the heat and water from green H2 production, the excess oxygen created during the electrolysis process can also be repurposed. For example, through strategic planning and sector integration, the oxygen can be used in wastewater treatment facilities, for medical purposes, or in industries to boost energy efficiency in furnaces and combustion processes. This way we get the most out of the energy input for H2 production while limiting the waste of valuable resources.

Case: Excess heat from H2 production. Over the coming years, the power demand for H2 production will be substantial and will only continue to increase, driven largely by electrolysis (FIG. 4).62 However, electrolysis wastes a lot of heat, and we can either let this disappear into the atmosphere, or leverage it to heat our homes, offices and hot water supply.

This heat potential can only be utilized if we plan our H2 production wisely. For example, electrolysis plants must be constructed near infrastructure linking them to heat consumers, such as district energy networks or industrial clusters. In fact, this can already be done today. Several projects are underway and can soon distribute the excess heat from electrolysis plants through district energy systems to heat homes.58,59

Several factors influence how much of the excess heat can actually be put to use. For instance, using the full potential would require a large build out of district energy. Additionally, while all regions have some demand for heat, not all regions have the same demand for heat. However, the theoretical potential of recovering excess heat from electrolysis is so enormous that it would be a severe policy mistake not to consider it when planning future energy infrastructure around the globe.

On a global scale, we can theoretically recover 1,917 TWhr of heat from H2 electrolysis in 2050 and redistribute it as district heat if the H2 production facilities are located near a suitable district energy system. To put this into perspective, 1,917 TWhr of heat is equivalent to more than 80% of today’s global heat generation from coal, the largest source of heat. In the EU alone, about 114 TWhr can be recovered already by 2030, enough to cover Germany’s current domestic heating more than two times. In China, 440 TWhr−636 TWhr can be recovered in 2060, between 27% and 39% of China’s current heat generation in 2021.60

Latin America’s electrolytic H2 production can reach 6 MMt in 2030, with 45% produced in Chile. Chile needs 142 TWhr for electrolytic H2 production and can recover 31 TWhr of excess heat from this. Chile has already included district energy in its future planning, and one roadmap suggests that in 2050, 40% of Chile’s heat demand can be covered through district heating and that excess heat should be integrated in this.61

Of course, these potentials are theoretical. The actual potential depends on several factors such as local heat demand, vicinity to district energy, and how efficient electrolysis will be in the future. However, they demonstrate that if district energy and excess heat are considered in long-term energy system planning, it can be a key contributor to reaching the 1.5°C target.

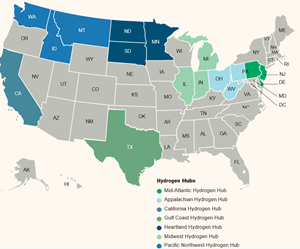

Case: Will the U.S. push for clean H2 become a wasted opportunity? In October 2023, the Biden-Harris Administration announced a $7 B public investment in seven regional clean H2 hubs to accelerate the domestic market for low-cost, clean H2.62,63 Part of a larger $1.2-T bill to invest in infrastructure across the U.S., the purpose of the hubs is to reduce emissions across particularly hard-to-decarbonize sectors and industrial processes, namely, heavy-duty transportation and chemical, steel and cement manufacturing. The U.S. Department of Energy (DOE) claims that the hubs will eliminate nearly 25 metric MMt of CO2 emissions from end uses annually.64

Together, the seven hubs will produce nearly 3 metric MMtpy of clean H2, which the White House defines as H2 stemming from renewables, nuclear, biomass or natural gas, leveraging CCS for any associated carbon emissions.65 Of the $7 B allocated to the hubs, roughly two-thirds are associated with electrolysis-based production, while the remaining one-third will support other forms of H2 production.

Assuming that two-thirds of the H2 will be electrolytic, the U.S. will need 111 TWhr/yr of electricity for splitting water. Vast amounts of heat will be wasted, and actually, 24 TWhr of excess heat can be reused in district energy systems, something we can already do today. In 2022, the U.S. used 106 TWhr of coal, oil, and gas to generate heat. This means that the theoretical potential for recoverable excess heat from electrolysis corresponds to more than 20% of the heat generated from fossil fuels in the U.S.66

There is incredible potential for excess heat to be integrated into the energy system. For example, district heating networks and industrial clusters are great candidates for the reuse of excess heat, so long as the construction of electrolysis plants and greater H2 networks are planned strategically. In fact, there is a large overlap between residential and commercial low-temperature heating demand and the regions where the hubs are to be constructed.67 This is especially true in states such as California, Pennsylvania, Illinois, Minnesota, Ohio and Michigan, where expansive district energy networks serve some of the country’s largest and most energy-intensive cities, such as Chicago and Detroit.

While heating is not in high demand all year round all across the country, the contribution of excess heat to year-long hot water supply and seasonal space heating through district energy networks can enable substantial reductions in the use of fossil fuels for heat generation. Additionally, it will not only reduce emissions: reusing excess heat can also cut costs. Every unit of excess heat integrated into district heating networks is one less unit that network owners need to purchase from fossil-derived energy sources. In other words, with excess heat, the energy has already been purchased, but we are currently just letting it (and dollar bills) evaporate into thin air (FIG. 5).

Of course, the potential to reuse excess heat from the proposed regional clean H2 hubs can only be realized if strategic energy planning prioritizes proximity to district energy networks and other significant sources of heat consumption, such as industrial clusters. To avoid a becoming a wasted opportunity to reduce emissions and save money, it is critical that politicians and other key decision makers put excess heat at the center of the clean H2 revolution, both in the U.S. and beyond. H2T

LITERATURE CITED

32 Danfoss estimates based on Buitendach et al. (2021). Effect of a ripple current on the efficiency of a PEM electrolyser. Results in Engineering, vol. 10, p. 1-13.

33 London’s annual electricity consumption in buildings and transport in 2018 was 37.82 TWh (Mayor of London (2022). London annual energy usage.) and we will need 14 800 TWh of electricity for hydrogen production in 2050 (IEA (2022). World Energy Outlook, p. 136.). 1 % of 14 800 TWh is 148 TWh. 148 TWh/37.82 TWh = 3.8, almost four times London’s electricity consumption in 2018.

34 Clean Energy Wire (2021). More renewables curbed to stabilise German power Grid – report.

35 IEA (2023). Energy Efficiency: The Decade for Action, p. 13.

36 Sepulveda et al. (2021). The design space for long-duration energy storage in decarbonized power systems. Nature Energy, p. 506-516.

37 Ea Energy Analyses (2023). Value of Demand Flexibility in the European Power Sector.

38 Reuters (2023). Europe's spend on energy crisis nears 800 billion euros.

39 The EU produced 2641 TWh of electricity in 2022, of which 19.6% or 517 TWh stemmed from natural gas. (EU (2023). Infographic - How is EU electricity produced and sold?.)

40 Joint Research Center (2023). Consumption Footprint Platform | EPLCA.

41 Danfoss (2023). Danfoss Impact No. 4. Energy Efficiency 2.0: Engineering the Future Energy System.

42 Andersson et al. (2019). Large-scale storage of hydrogen. International Journal of Hydrogen Energy, vol. 44, issue 23, p. 11901-11919.

43 CLOUGLOBAL (2023). Pros and Cons of Hydrogen Energy Storage: Is Worth the Investment?.

44 Energinet (2023). Hydrogen Market Assesment Report for Denmark and Germany, p. 12.

45 Klimarådet (2023). Sikker elforsyning med sol og vind.

46 Kountouris et al. (2023). A unified European hydrogen infrastructure planning to support the rapid scale-up of hydrogen production. Research Square, 1, p. 1-18.

47 Choudhury, Subhashree (2021). Flywheel energy storage systems: A critical review on technologies, applications, and future prospects. Internal Transactions on Electrical Energy Systems, vol. 31, issue 9.

48 Deloitte (2023). Green hydrogen: Energizing the path to net zero, p. 16.

49 Firth et al. (2019). Quantification of global waste heat and its environmental effects. Applied Energy, vol. 235, p. 1325.

50 Firth et al. (2019). Quantification of global waste heat and its environmental effects. Applied Energy, vol. 235, p. 1325.

51 Euroheat & Power (2023). DHC Market Outlook, p. 3.

52 Connolly et al. (2013). Heat Roadmap Europe 2: Second Pre-Study for the EU27. Department of Development and Planning, Aalborg University, p. 54.

53 Connolly et al. (2013). Heat Roadmap Europe 2: Second Pre-Study for the EU27. Department of Development and Planning, Aalborg University, p. 54.

54 Heat demanded by residential and service sector buildings, also called “low-temperature heat demand”, according to 2015 data from the Heat Roadmap Europe 4. This demand does not cover industrial heat demand as required input temperatures are too high for excess heat recovery technologies.

55 Heat Roadmap Europe (n.d.). Pan-European Thermal Atlas 4.3.

56 Moreno et al. (2022). The European Waste Heat Map. ReUseHeat project - Recovery of Urban Excess Heat.

57 Luo et al. (2017). Mapping potentials of low-grade industrial waste heat in Northern China. Resources, Conservation and Recycling, vol. 125, p. 335-348.

58 TVIS (2022). Fjernvarme til 1300 husstande mere fra Danmarks første PtX-aftale.

59 COWI (2023). Kassø PTX (E-methanol) - Miljøkonsekvensrapport, p. 24.

60 For descriptions on how the excess heat potentials are estimated, we refer you to the Appendix: Excess heat from electrolysis.

61 For descriptions on how the excess heat potentials are estimated, we refer you to the Appendix: Excess heat from electrolysis.

62 BloombergNEF (2022). New Energy Outlook 2022.

63 The White House (2023). Biden-Harris Administration Announces Regional Clean Hydrogen Hubs to Drive Clean Manufacturing and Jobs.

64 Office of Clean Energy Demonstrations. Regional Clean Hydrogen Hubs Selections for Award Negotiations.

65 The White House (2023). Biden-Harris Administration Announces Regional Clean Hydrogen Hubs to Drive Clean Manufacturing and Jobs.

66 For descriptions on how the excess heat potentials are estimated, we refer you to the Appendix: Excess heat from electrolysis.

67 Oh, H. & Beckers, K (2023). Geospatial Characterization of LowTemperature Heating and Cooling Demand in the United States. p. 3-8. Golden, CO: National Renewable Energy Laboratory. NREL/CP-5700-84708. https://www.nrel.gov/docs/fy23osti/84708.pdf