News

Online Feature: Green H2: A critical balancing act─Part 3

Mika Kulju, President, Danfoss Drives

Part 3 of this series addresses decision-makers’ need to establish supportive regulatory and economic frameworks to enable a large-scale rollout of green H2. Key policy principles include prioritizing energy efficiency and direct electrification, using green H2 for challenging sectors, ensuring H2 production is complemented by renewable energy, repurposing excess heat and integrating sectors for efficient resource use. Click here to read Part 2.

H2 is an effective energy carrier, and the end uses are many. However, just because it is effective does not mean that it is efficient. Indeed, green H2 production is costly and requires large amounts of renewable electricity when produced at scale. In the electrolysis process, energy is lost. And in cases where we need to convert H2 back to electricity or further into other forms of low-emission fuels, more energy is lost. H2 will play a key role in decarbonizing our energy system, but it must be considered a costly and therefore limited resource.

It will require substantial investments to produce the low-emissions H2 required in 2050.68 But how much H2 will we actually need in the future? The EU plans to produce and import a total of 666 TWh of H2 by 2030, all produced by low-emissions sources.69 This is equivalent to the energy production from about 140 nuclear power plants.70 One analysis suggests that the EU can reduce the need for H2 to about 116 TWh – less than a fifth – by focusing on energy efficiency and electrification while massively scaling solar and wind energy, district heating, and highly efficient heat pumps.71

Regardless, 116 TWh of H2 by 2030 is still ambitious and will require a very large amount of electricity, which will pose challenges to the stability and security of the energy grid. The necessary investments will also be tremendous, underlining that a cost- efficient transition must consider where the greatest potential benefits of H2 can be yielded. Less than 1% of today’s H2 production is based on water electrolysis and makes green H2. Decarbonizing current production facilities is essential, and gray H2 production facilities should start repurposing and adapting to green H2 production, making use of existing H2 infrastructure.

Producing green H2 is energy intensive, and we will need vast amounts of electricity for this. This means that we must use H2 as a last resort in sectors that are otherwise hard to decarbonize, such as long-distance shipping, international aviation, and steel and cement production. Many countries are considering powering their electricity production or heat supply with H2. While this is a good application when used for meeting peak demand, it is highly inefficient to use H2 as a regular source of electricity or heat. For primary use, there are many better alternatives, such as renewables and heat pumps. H2 will be a scarce resource, so the use of it must be considered carefully.

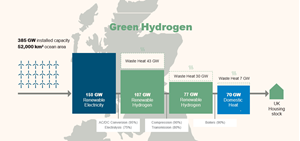

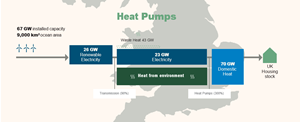

Using H2 the right way. There are efficient and inefficient ways to use H2. An example of inefficient use of H2 is space heating.72 If we were to provide the UK with domestic heating from low-emissions H2 produced from offshore wind farms, we would need a capacity of 385 GW to produce enough H2 to heat the UK. However, the global offshore wind capacity is only expected to grow by 380 GW in the next ten years.73 But if we instead heated the UK with heat pumps and district energy, we would need a much smaller capacity. With heat pumps, we would only need a capacity of 67 GW of offshore wind farms, and even less power if we supplied the more densely populated areas with district heating – this way it would also be easier to use excess heat from surrounding buildings and processes to heat local homes. The offshore wind farms for the H2 solution would take up 52,000 km2.

However, it would take up only 9,000 km2 for offshore wind farms to supply heat pumps. Essentially, it would take one-sixth of the power to get the British through the winter with heat pumps instead of H2, and even less if heat pumps were combined with district energy.74

Fortunately, with a ban on boilers in all homes built from 2025, the debate on whether to use H2 for home heating has come to an end in the UK.75 However, there are many other countries, especially in Europe, where the discussion is still very much alive.76,77 The science unequivocally shows that heat pumps and district energy are more effective solutions and should be considered the primary sources for home heating in a decarbonized future.78

In the following cases, we take a deep dive into use cases where H2 is the wise choice, such as the production of virtually carbon-free fuels, as well as how it can be a great lever to decarbonize food production (FIGS. 6a and 6b).

Case: eFueling the future. Where we cannot yet electrify efficiently, we can at least decarbonize. For example, steel and cement production require extremely high temperatures – so high, in fact, that electric furnaces cannot yet produce them efficiently. And while we are seeing positive technological developments for electrifying high-temperature processes, these are not currently operating at scale, leaving us with few options other than fossil fuels. Similarly, in industries such as aviation and long-distance shipping, electric motors actually can produce enough power. However, they also require batteries, which are far too heavy and require too much space to be practical. In both cases, H2 is our best hope for decarbonization (FIG. 7).

H2 can be converted into alternative fuels, such as eAmmonia, eKerosene and eMethanol. These can then be used to fuel industries or processes requiring either high temperatures or long-distance mobility. Additionally, though still in development, H2 can be utilized in fuel cells, where it is mixed with oxygen and releases energy in the process. With a fuel cell, ships, planes, and long-distance trucks can be fueled without fossil sources.79,80

At each step in the conversion process, there is energy loss. For example, when converting electricity to H2, there is an energy loss of roughly 30%.81 When then converting that H2 back into some other form of deployable energy (such as eFuels), there is an additional energy loss. Because of this energy loss, these eFuels are not necessarily more energy efficient than fossil fuels. However, assuming that the electricity used to create the initial H2 comes from renewable sources, as the vast majority will in our 2050 energy system, this is a viable pathway to decarbonize these energy-intensive sectors, where until recently decarbonization was seen as nothing but a pipe dream.

Case: Decarbonizing agriculture with low-emissions ammonia. Agriculture emits 12% of global emissions, a number which is only projected to increase over the coming decade.82,83 It is one of the most challenging sectors to decarbonize, given the GHG-intensive nature of crop and livestock production. This carbon intensity is in part due to fertilizer production. Ammonia is an essential nutrient in fertilizer, and 70% of today's ammonia is used in fertilizer production. Without it we cannot grow crops. However, the production of ammonia accounts for about 1.3% of global CO2 emissions and 2% of the final global energy consumption (FIG. 8).84

By 2040, the ammonia demand for fertilizer will have almost doubled and the total demand will have more than doubled.85 And regardless of this increasing demand, the emissions from ammonia production must be reduced by 95%.86 Decarbonizing ammonia production with H2 can prove one of the greatest levers in decarbonizing our food production and this is one of the areas that can be decarbonized without disrupting the existing production processes in agriculture.87

Today, ammonia is produced by splitting natural gas into H2 and CO2, and then combining the H2 with nitrogen from the atmosphere under high pressure and temperature – also known as the Haber-Bosch process.88 This is a very GHG-intensive process since the CO2 is released into the atmosphere. Actually, 1.6 t−2.6 t of CO2 are emitted for every ton of ammonia produced.89,90,91 In the future, the H2 and electricity for ammonia production can be supplied from renewable sources, drastically lowering the climate footprint from ammonia.92 According to the IEA, about one-third of the GHG reductions in ammonia production must stem from electrolytic H2 to reach the Paris goals.93

There are currently nearly 250 projects worldwide in the pipeline that plan to produce electrolysis- based ammonia, and international organizations and policy makers are increasingly realizing that green ammonia is a part of the future.94,95

POLICY RECOMMENDATIONS

Now is the time for decision-makers to set the right regulatory and economic framework for an efficient large-scale rollout of H2. Public support is needed at the local, regional and national level to address regulatory barriers and improve implementation plans. Similarly, we must stimulate more international cooperation and cross-industry collaboration and synergies. These are also likely to be a driving force behind innovation, demand and growth of green H2.

H2 has its complications, and those need to be addressed to unlock the full potential of a H2 economy. Today, H2 is largely being produced with natural gas, and less than 1% of today’s global production is green H2, produced via water electrolysis based on renewable electricity. To reach the goals of the Paris Agreement, significant upscaling needs to happen sooner rather than later.

A good place to start would be to repurpose gray H2 production facilities and have them produce green H2, making good use of the already established H2 infrastructure. Moreover, the demand for H2 is still overwhelmingly focused on traditional purposes, such as ammonia production or refining, while use in hard-to-abate sectors like steel-making or heavy transport is still very limited.96 As such, H2 is still an immature technology in the green transition. The following overall principles and policy measures can accelerate a transition to a cost-efficient deployment of green H2. Overall policy principles include:

- Energy efficiency and electrification first. While green H2 can open doors for the transition to a green economy, focus should remain on direct electrification of as many elements of our energy systems as possible. Next, a rapid scale up of green H2 as opposed to high-emission H2 is needed.

- Use H2 for hard-to-abate sectors. Green H2 provides a means to decarbonize and indirectly electrify sectors in which full decarbonization is not yet possible. This includes decarbonizing heavy industry, ammonia to decarbonize agriculture, and using green H2 for eFuels.

- Build out of H2 must go hand in hand with the build out of renewables. Electrolysis will have a significant pull on the electricity grid, and H2 production must not overload an increasing demand. Renewable energy sources driving H2 production must be auxiliary.

- Leverage excess heat from green H2 Electrolytic H2 production generates a substantial proportion of heat loss. If H2 production is planned strategically, much of the excess heat can be repurposed in district heating or microgrids.

- Examine potential sector integration opportunities. Green H2 production has a large electricity pull, high water consumption and vast amounts of excess heat accessible. Before building facilities, thorough sector integration due diligence must be conducted. For instance, areas with water scarcity issues might benefit from optimized desalination facilities, which are critical in providing the pure water needed for electrolysis as well as drinking water.

Incentivize green H2 production:

- Subsidize research and development to increase feasibility of green H2 High production costs limit the economic feasibility of electrolysis facilities. Investment costs are estimated to be reduced by 80% if electrolyzers become cheaper. Lowering tariffs and creating tax incentives, such as the tax credit on green H2 in the Inflation Reduction Act, are pivotal (IRA Clean H2 Production Credit). Financing instruments like the EU H2 Bank can also play an important role in facilitating investments into the green H2 value chain. On the demand side, research and development into novel applications such as green H2 for steel-making or heavy transport should also be supported.

- Strengthen the willingness of investors and customers to pay. Clear goals supported by national H2 strategies create predictability and stability for investors. Ensuring future demand for green H2 – especially in hard-to-abate sectors – is key to de-risk projects today and incentivize upstream investments. Accommodating the lack of long-term viability is therefore essential in creating a green H2

- Lower tariffs on H2 as a commodity. Address barriers limiting trade and investment in the entire green H2 supply chain. Tariffs on electrolyzers and H2 derivatives create barriers for promoting green H2. To increase green H2 demand and incentivize investments, green H2 and its derivatives should benefit from tax and tariff exemptions. Phasing out subsidies on fossil fuels would further close the economic gap between gray, blue and green H2.

- Incentivize H2 transition through build out of infrastructure. In many use cases, infrastructure will inform applicability. Lack of ambition and planning of H2 infrastructure limit investors and market actors’ ability to predict green H2 In some cases, it is both possible and feasible to retrofit existing natural gas pipelines to enable them to transport H2.

- Regulate government procurement strategies to stimulate a green H2 Introduce requirements for hard-to-abate sectors’ deliveries on government contracts like green steel in new buildings and long-haul shipping imports running on eFuels.

- Incentivize investments in developing countries with high renewable energy potential. Many developing economies have access to vast amounts of renewable energy and will thus be able to produce a lot of green H2 when they receive the investments needed to scale up production. Apart from sparking developing countries’ economy by exporting, it can support other economies’ H2 import requirements.

Produce efficiently:

- Implement high standards for efficient H2 To lower the amount of renewable energy used on green H2 production, standards should dictate the efficiency of production. For example, regulation incentivizing the use of high-efficiency grid converters and eliminating inefficient pressurization methods and technologies could be considered.

- Ensure H2 production does not add to an increasing water scarcity issue. All forms of H2 production are water intensive. For example, conventional, carbon-intensive methods of H2 production, as well as production utilizing carbon capture and storage, require large amounts of water for steam generation and cooling. But despite requiring water for electrolysis, green H2 is actually the least water-intensive production method. Careful planning of production and use of efficient desalination technologies are pivotal.

- Use H2 as a tool to increase flexibility. Efficient H2 production is not just about how we produce it, but also when we produce it. Producing green H2 in periods of high renewable electricity supply and low demand means we can store it for peak demand periods, accelerating a phase out of fossil-fuel power plants. Flexible H2 production can also balance and stabilize the grid, meaning renewable electricity generation does not have to be curtailed. H2T

LITERATURE CITED

68 In 2030 we will need 90 Mt (10.79 EJ/9 million kg) H2 (IEA (2022). World Energy Outlook, p. 136.). The lowest price is $1.3 to 3.5/kg H2 (IEA (2021). Global H2 Review: Executive Summary.). 90 billion kg H2 X $1.3 to 3.5/kg H2 = USD 117-315 billion investments needed.

69 European Commission (n.d.). H2. Assuming a lower heating value of H2 of 33.3 kWh/kg.

70 In 2017, the U.S. nuclear power plant R.S. Ginna (American Geosciences Institute (n.d.). How much electricity does a typical nuclear power plant generate?) produced 4,697,675 MWh or 4,697 TWh electricity. The EU plans to produce and import a total of 666 TWh H2. 666 TWh/4.697 TWh = 142 nuclear plants like R.S. Ginna.

71 Agora Energiewende (2023). Breaking free from fossil gas: A new path to a climate-neutral Europe, p. 11.

72 Hydrogen Insight (2023). A total of 37 independent studies have now concluded there will be no significant role for H2 in heating homes.

73 Global Wind Energy Council (2023). Global Offshore Wind Report 2023. p. 2.

74 Hydrogen Science Coalition (2022). H2 for heating? A comparison with heat pumps (Part 1).

75 The Conversation (2023). UK ban on boilers in new homes rules out H2 as a heating source.

76 Reuters (2023). German parliament passes law to phase out gas and oil heating.

77 Trade.gov.pl (2024). Poland’s H2 Strategy: A Green Future. Polish Ministry of Economic Development and Technology.

78 Hydrogen Insight (2023). A total of 37 independent studies have now concluded there will be no significant role for H2 in heating homes.

79 Odenweller et al. (2022). Probabilistic feasibility space of scaling up green H2 supply. Nature Energy 7, 854-865.

80 Hydrogen Science Coalition (2022). H2 for heating? A comparison with heat pumps (Part 1).

81 Buitendach et al. (2021). Effect of a ripple current on the efficiency of a PEM electrolyser. Results in Engineering 10, 1-13.

82 In 2020, the global emissions including LUCF was 47,513.2 megaton CO2e and agriculture emitted 5,865.5 megaton CO2e, 12.3% of the global emissions (Climate Watch (n.d.). Data Explorer. Filter: Data sources: Climate Watch, Parties and regions: World, Sectors: ‘Agriculture’ and ‘Total including LUCF’, Gases: ‘All gases’, Year: ‘2020’)

83 OECD (2023). Production growth to slow in step with population, while geopolitical tensions, climate change, animal and plant diseases and price volatility of critical farming inputs pose long-term uncertainty.

84 IEA (2021). Ammonia Technology Roadmap.

85 IRENA and AEA (2022), Innovation Outlook: Renewable Ammonia. International Renewable Energy Agency, Abu Dhabi, Ammonia Energy Association, Brooklyn, p. 15.

86 IEA (2021). Ammonia Technology Roadmap, p.61.

87 McKinsey & Company (2023). From green ammonia to lower-carbon foods.

88 Yale Environment 360 (2022). From Fertilizer to Fuel: Can ‘Green’ Ammonia Be a Climate Fix?

89 Elshishini, Shadia (2024). Product carbon footprint methodology for ammonia production by conventional steam reforming – A case study. European Journal of Sustainable Development Research, vol. 8, issue 1.

90 Liu et al. (2020). Life cycle energy use and greenhouse gas emissions of ammonia production from renewable resources and industrial byproducts. Green Chem., 2020, 22, 5751-5761.

91 IEA (2021). Ammonia Technology Roadmap.

92 Stocks et al. (2022). Global emissions implications from co-combusting ammonia in coal fired power stations: An analysis of the Japan-Australia supply chain, Journal of Cleaner Production, Volume 336.

93 IEA (2021). Ammonia Technology Roadmap, p.61.

94 IEA (2023). H2 Production and Infrastructure Projects Database. The ‘H2 production projects’ database is filtered to show all electrolysis- based projects, with ammonia as an end-use, being conceptualized, undergoing feasibility studies, or under construction.

95 IRENA and AEA (2022). Innovation Outlook: Renewable Ammonia. Chapter 4.6 Outlook for the ammonia economy. p. 90.

96 IEA (2023). Energy System – H2.

97 Hauch, A., R. Küngas, P. Blennow, A. B. Hansen, J. B. Hansen, B. V. Mathiesen, and M. B. Mogensen. “Recent Advances in Solid Oxide Cell Technology for Electrolysis.” Science 370, no. 6513 (October 9, 2020): eaba6118. https://doi.org/10.1126/science.aba6118.

98 The Danish Energy Agency (2024). Technology Data for Renewable Fuels. Data Sheets for energy carrier generation and conversion. Sheets: “86 AEC 100 MW”, “86 PEMEC 100 MW”, and “SOEC 100 MW”.

99 IEA (2022). World Energy Outlook 2022, p. 136.

100 IEA (2023).Energy Statistics Data Browser. Filter: Energy topic: Electricity and heat, Indicator: Heat generation by source, Country or region: World).

101 EU (2022). Energy – H2.

102 EU (2020). EUR-Lex. Document 52020DC0301. Communication from the commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions - A H2 strategy for a climate-neutral Europe.

103 Statistiches Bundesamt (2017). Balance sheet of heat supply, total.

104 IEA (2022). Opportunities for H2 Production with CCUS in China. Executive summary.

105 IEA (2023). Energy Statistics Data Browser. Filter: Energy topic: Electricity and heat, Indicator: Heat generation by source, Country or region: People’s Republic of China.

106 The White House (2023). Biden-Harris Administration Announces Regional Clean H2 Hubs to Drive Clean Manufacturing and Jobs.

107 IEA (2023). Global H2 Review 2023, p. 65.

108 IEA (2023).Energy Statistics Data Browser. Filter: Energy topic: Electricity and heat, Indicator: Heat generation by source, Country or region: United States.

109 IEA (2023). Global H2 Review 2023, p. 66.

110 District Energy in Cities Initiative (n.d.). Chile.

111 Paardekooper et al. (2019). Heat Roadmap Chile: Quantifying the potential of clean district heating and energy efficiency for a long-term energy vision for Chile. Executive Summary. Department of Development and Planning, Aalborg University.